目录

Benefits of Using Liquid Adhesion Promoter in Additive Fabrication

Additive fabrication, also known as 3D printing, has revolutionized the manufacturing industry by allowing for the creation of complex and customized parts with ease. However, one of the challenges that additive fabrication Shops face is ensuring proper adhesion between the printed layers. This is where liquid adhesion promoters come into play.

Liquid adhesion promoters are additives that are applied to the build platform or the printed part itself to improve adhesion between the layers. These promoters work by creating a strong bond between the printed material and the build platform, preventing warping, delamination, and other issues that can arise during the printing process.

One of the key benefits of using liquid adhesion promoters in additive fabrication is improved print quality. By ensuring proper adhesion between the layers, promoters help to create parts that are more accurate and have a smoother surface finish. This is especially important for parts that require tight tolerances or intricate details.

| Number | Product Name |

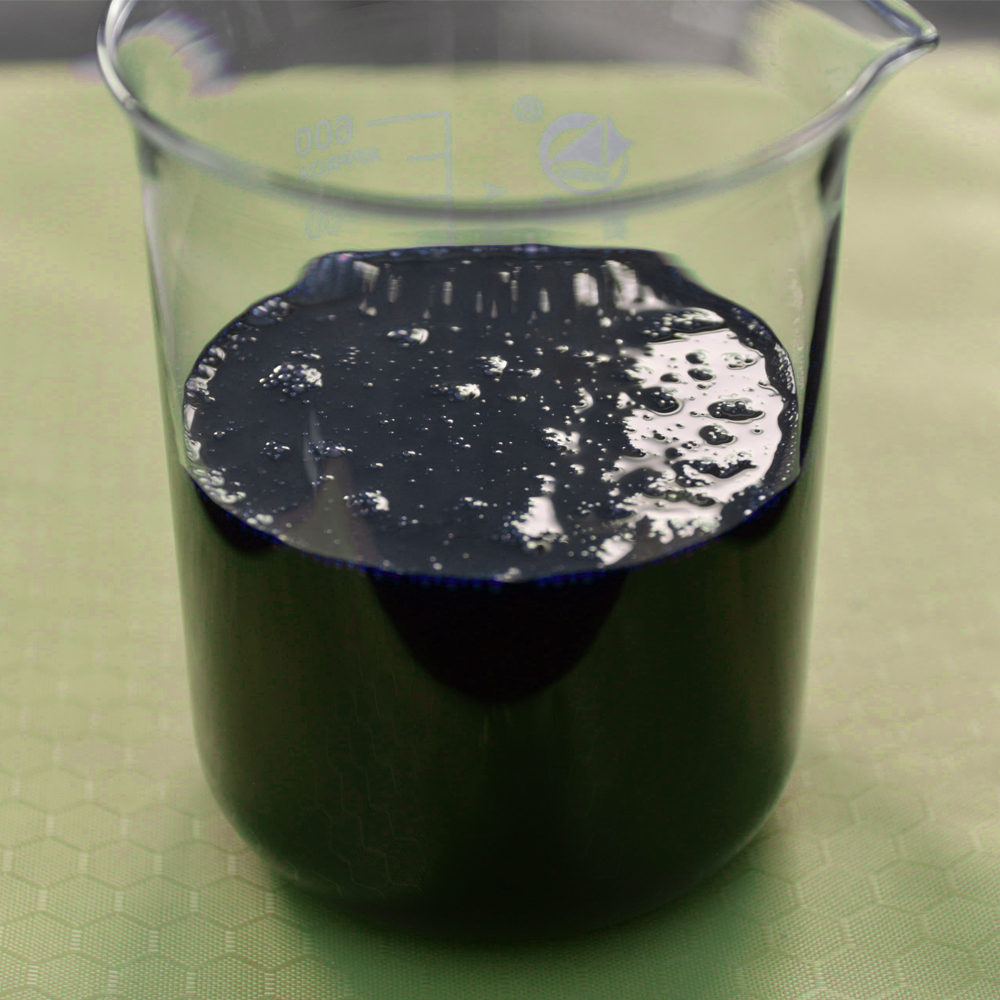

| 1 | asphalt anti-stripping additive |

Another benefit of using liquid adhesion promoters is increased print success rates. By reducing the likelihood of warping and delamination, promoters help to minimize the risk of print failures, saving time and materials in the process. This is particularly important for additive fabrication shops that rely on consistent and reliable printing results.

In addition to improving print quality and success rates, liquid adhesion promoters also offer cost savings. By reducing the need for reprints due to failed prints, promoters help to lower overall production costs. This is especially beneficial for additive fabrication shops that produce large volumes of parts on a regular basis.

Furthermore, liquid adhesion promoters are easy to apply and can be used with a wide range of materials, making them versatile and convenient for additive fabrication shops. Whether printing with ABS, PLA, PETG, or other materials, promoters can help to ensure strong adhesion between the layers, regardless of the material being used.

Overall, the benefits of using liquid adhesion promoters in additive fabrication are clear. From improved print quality and success rates to cost savings and versatility, promoters offer a range of advantages for additive fabrication shops looking to optimize their printing processes.

In conclusion, liquid adhesion promoters are a valuable tool for additive fabrication shops looking to enhance their printing capabilities. By improving adhesion between layers, promoters help to create parts that are more accurate, reliable, and cost-effective. Whether printing with ABS, PLA, PETG, or other materials, promoters offer a versatile and convenient solution for achieving high-quality prints. With their numerous benefits, it’s clear that liquid adhesion promoters are a must-have additive for any fabrication shop looking to take their printing to the next level.

How to Choose the Right Liquid Adhesion Promoter for Your Fabrication Shop

Liquid adhesion promoters are essential additives for any fabrication shop looking to improve the adhesion of coatings, inks, or adhesives to a variety of substrates. These promoters work by creating a strong bond between the substrate and the applied material, ensuring a durable and long-lasting finish. However, with so many options available on the market, choosing the right liquid adhesion promoter for your fabrication shop can be a daunting task. In this article, we will discuss some key factors to consider when selecting a liquid adhesion promoter to ensure optimal performance and results.

One of the first things to consider when choosing a liquid adhesion promoter is the type of substrate you will be working with. Different promoters are designed to work with specific types of materials, so it is important to select a promoter that is compatible with the substrate you will be using. For example, if you are working with metal substrates, you will need a promoter that is specifically formulated for metal surfaces to ensure proper adhesion.

Another important factor to consider is the type of material you will be applying to the substrate. Some liquid adhesion promoters are designed to work with specific types of coatings, inks, or adhesives, so it is important to choose a promoter that is compatible with the material you will be using. This will help ensure that the promoter effectively bonds the material to the substrate, resulting in a strong and durable finish.

In addition to compatibility with substrates and materials, it is also important to consider the application method of the liquid adhesion promoter. Some promoters are designed for spray application, while others are better suited for brush or roller application. It is important to choose a promoter that is compatible with your preferred application method to ensure easy and efficient application.

Furthermore, it is important to consider the drying time and curing process of the liquid adhesion promoter. Some promoters require a longer drying time before the material can be applied, while others may require a specific curing process to achieve optimal adhesion. It is important to choose a promoter that fits within your production schedule and allows for efficient workflow in your fabrication shop.

Cost is also an important factor to consider when choosing a liquid adhesion promoter for your fabrication shop. While it is important to invest in a high-quality promoter that will deliver optimal results, it is also important to consider the overall cost of the product. It is important to find a balance between quality and cost to ensure that you are getting the best value for your money.

In conclusion, choosing the right liquid adhesion promoter for your fabrication shop is essential for achieving strong and durable adhesion between substrates and applied materials. By considering factors such as substrate compatibility, material compatibility, application method, drying time, curing process, and cost, you can select a promoter that will meet your specific needs and deliver optimal results. With the right liquid adhesion promoter, you can enhance the performance and durability of your coatings, inks, and adhesives, ensuring high-quality finishes for your fabrication projects.