目录

Understanding the Market Trends and Industry Status of Foam Plastics

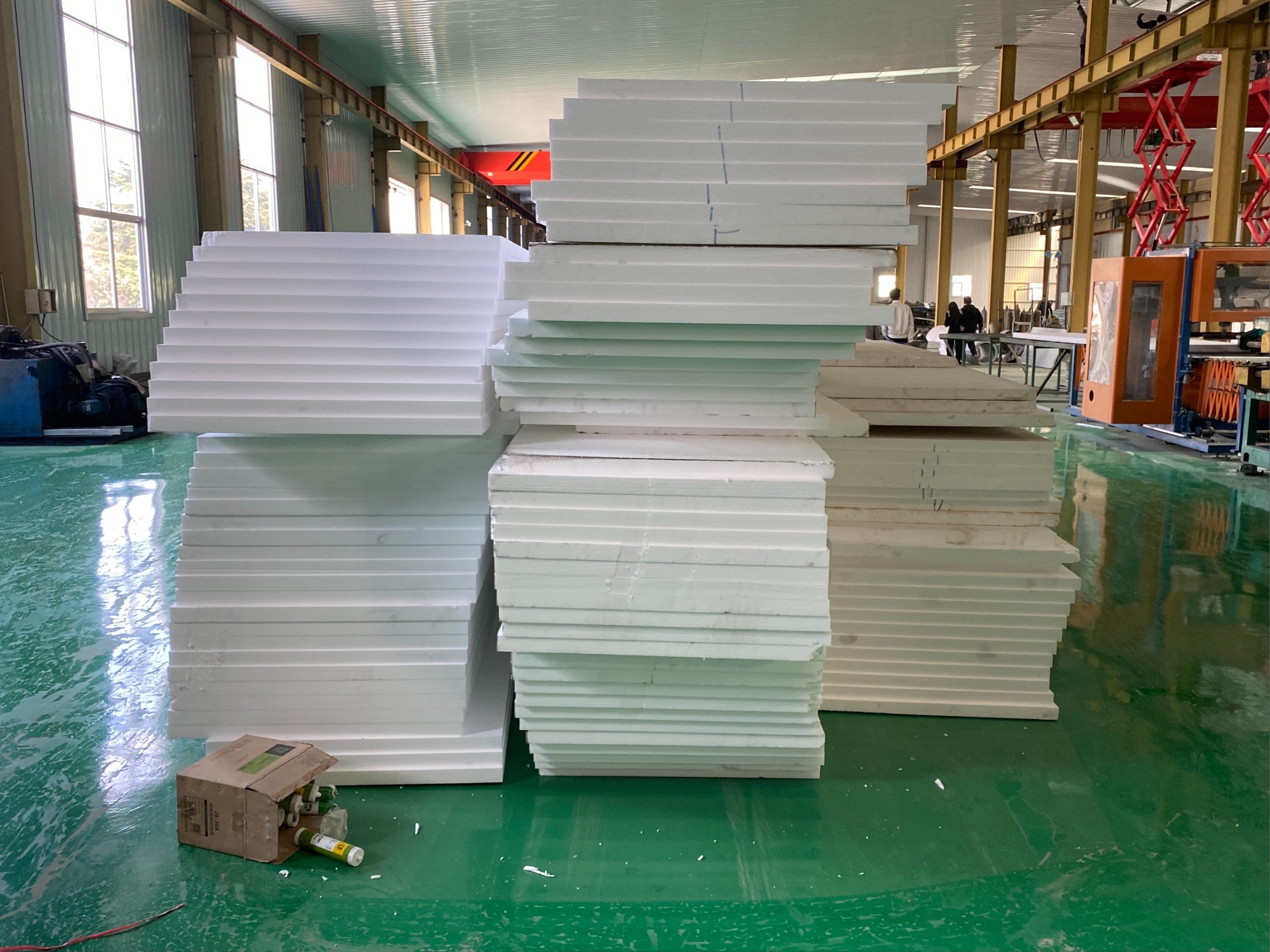

Foam plastics have become an integral part of our daily lives, with a wide range of applications in various industries such as packaging, construction, automotive, and electronics. The market for foam plastics has been steadily growing over the years, driven by factors such as increasing demand for lightweight and durable materials, as well as the growing awareness of environmental issues and the need for sustainable solutions.

A recent survey and analysis of the market situation and industry status of foam plastics reveal some interesting trends and insights. One of the key findings is the increasing demand for foam plastics in the packaging industry, driven by the rise of e-commerce and the need for protective packaging materials. Foam plastics are lightweight, versatile, and offer excellent cushioning properties, making them ideal for protecting fragile items during shipping and handling.

Another important trend is the growing use of foam plastics in the construction industry, particularly in insulation applications. Foam plastics offer superior thermal insulation properties compared to traditional materials such as fiberglass and cellulose, helping to improve energy efficiency and reduce heating and cooling costs. With the increasing focus on sustainability and green building practices, foam plastics are also being used in the construction of energy-efficient buildings that meet strict environmental standards.

In the automotive industry, foam plastics are being used in a wide range of applications, from interior components such as seats and headliners to exterior parts such as bumpers and body panels. Foam plastics offer excellent impact resistance, noise reduction, and weight savings, making them an attractive choice for automakers looking to improve fuel efficiency and Safety standards. With the growing demand for electric vehicles and autonomous driving technologies, the use of foam plastics in the automotive industry is expected to increase further in the coming years.

The electronics industry is another key market for foam plastics, with applications ranging from protective packaging for delicate electronic components to thermal management solutions for electronic devices. Foam plastics offer excellent shock absorption and vibration damping properties, helping to protect sensitive electronics from damage during shipping and handling. With the increasing miniaturization of electronic devices and the growing demand for high-performance materials, foam plastics are playing an important role in ensuring the reliability and durability of electronic products.

Overall, the survey and analysis of the market situation and industry status of foam plastics indicate a positive outlook for the industry, with strong growth potential in key end-use sectors such as packaging, construction, automotive, and electronics. As consumer preferences shift towards sustainable and eco-friendly products, foam plastics manufacturers are increasingly focusing on developing innovative solutions that meet the evolving needs of the market.

In conclusion, foam plastics continue to be a versatile and indispensable material in a wide range of industries, offering unique properties and benefits that drive their widespread adoption. With ongoing research and development efforts focused on enhancing performance, sustainability, and recyclability, foam plastics are poised to play a key role in shaping the future of materials science and engineering.