Table of Contents

The Steel Used in the Construction of the Twin Towers

The construction of the Twin Towers, also known as the World Trade Center in New York City, was a monumental engineering feat that required the use of high-quality steel. The steel used in the construction of the Twin Towers was a special type known as ASTM A36 steel. This type of steel is known for its strength and durability, making it an ideal choice for a building of such magnitude.

The ASTM A36 steel used in the construction of the Twin Towers had a tensile strength of 58,000-80,000 psi, which is significantly higher than that of other types of steel. This high tensile strength made the steel resistant to bending and breaking, ensuring that the Twin Towers could withstand the forces of nature and the stresses of daily use.

In addition to its high tensile strength, the ASTM A36 steel used in the construction of the Twin Towers also had a high yield strength. This means that the steel could withstand a significant amount of stress before deforming or breaking. This was crucial for a building as tall and as heavily trafficked as the Twin Towers, as it needed to be able to support its own weight as well as the weight of the thousands of people who worked in and visited the buildings every day.

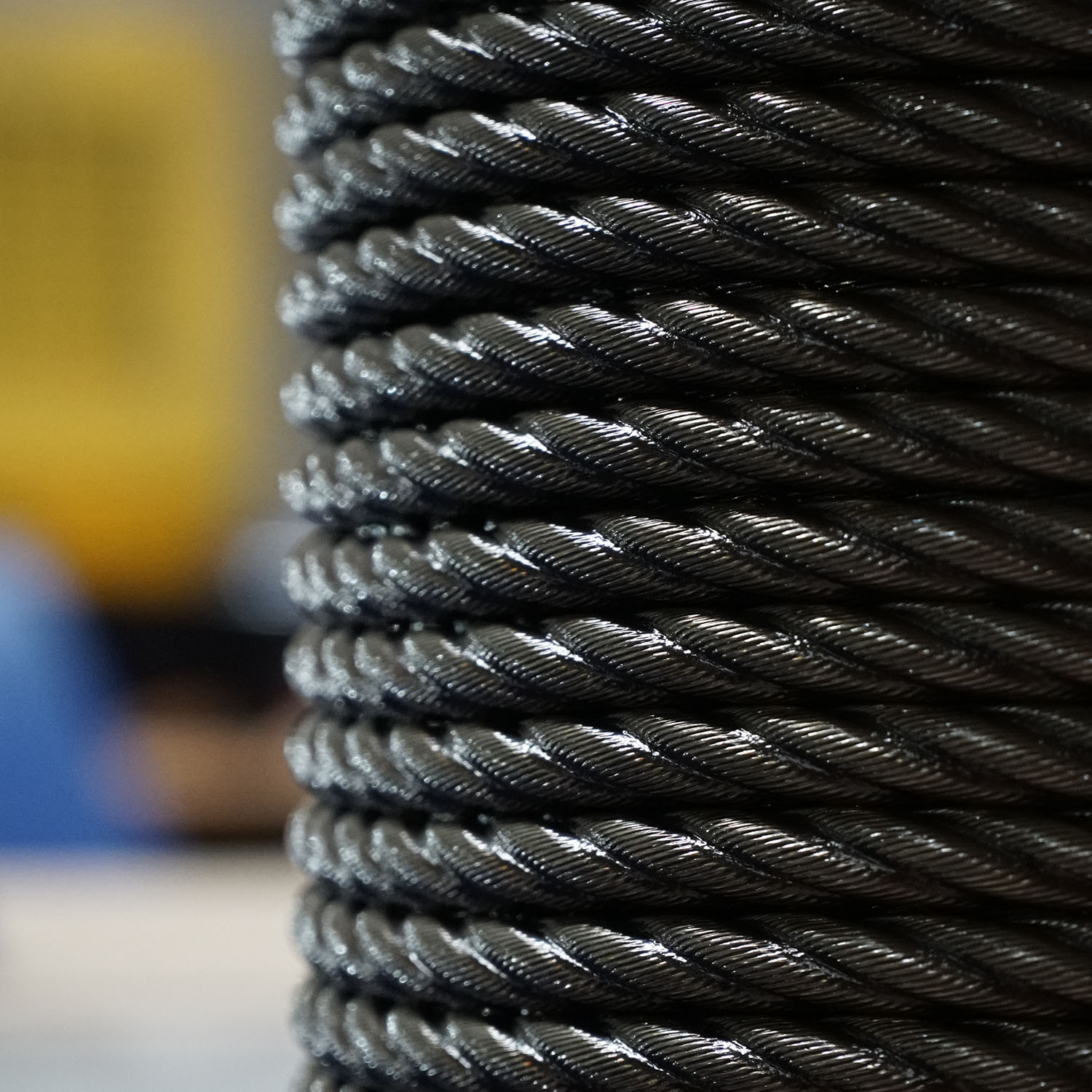

The diameter of the steel wire used in the construction of the Twin Towers was also carefully chosen to ensure the structural integrity of the buildings. The steel wire used in the construction of the Twin Towers was 9 gauge, which is equivalent to a diameter of 0.1144 inches. This diameter was chosen for its strength and flexibility, allowing the steel wire to be easily manipulated and shaped into the intricate designs required for the construction of the Twin Towers.

The steel used in the construction of the Twin Towers was not only strong and durable, but it was also fire-resistant. This was crucial for a building as tall as the Twin Towers, as fires are a common hazard in high-rise buildings. The steel used in the construction of the Twin Towers was coated with a special fire-resistant material that helped to prevent the spread of fires and protect the structural integrity of the buildings.

Overall, the steel used in the construction of the Twin Towers was carefully chosen for its strength, durability, and fire-resistance. The ASTM A36 steel used in the construction of the Twin Towers had a high tensile strength and yield strength, making it ideal for a building of such magnitude. The diameter of the 9 gauge steel wire used in the construction of the Twin Towers was also carefully chosen for its strength and flexibility. This combination of high-quality steel and careful design ensured that the Twin Towers were able to withstand the forces of nature and the stresses of daily use, making them one of the most iconic buildings in the world.

Understanding the Diameter of 9 Gauge Steel Wire

The Twin Towers, also known as the World Trade Center in New York City, were iconic symbols of the city’s skyline before the tragic events of September 11, 2001. These towers were constructed using a variety of materials, including steel. The steel used in the construction of the Twin Towers was a crucial component in their structural integrity and overall design.

The steel used in the construction of the Twin Towers was a high-strength, low-Alloy Steel known as ASTM A36. This type of steel is commonly used in construction due to its strength and durability. The steel used in the Twin Towers was specifically chosen for its ability to withstand the immense weight and stress placed on the buildings.

One important aspect of steel construction is the gauge of the steel wire used. The gauge of a steel wire refers to its diameter, with lower gauge numbers indicating thicker wire. In the case of the Twin Towers, the steel wire used was 9 gauge. This means that the diameter of the steel wire used in the construction of the Twin Towers was relatively thick, providing additional strength and support to the buildings.

Understanding the diameter of 9 gauge steel wire is important in the context of construction and structural engineering. Thicker steel wire, such as 9 gauge, is often used in applications where strength and durability are paramount. In the case of the Twin Towers, the use of 9 gauge steel wire helped to ensure the structural integrity of the buildings.

The diameter of 9 gauge steel wire is approximately 0.1144 inches, or 2.906 millimeters. This thickness is ideal for applications where high strength and durability are required, such as in the construction of tall buildings like the Twin Towers. The use of 9 gauge steel wire in the construction of the Twin Towers played a crucial role in their ability to withstand the forces placed upon them.

In addition to its strength and durability, 9 gauge steel wire is also relatively easy to work with. This makes it a popular choice for construction projects where precision and accuracy are important. The use of 9 gauge steel wire in the construction of the Twin Towers allowed for the creation of intricate and complex structural designs that helped to make the buildings stand out on the New York City skyline.

Overall, the steel used in the construction of the Twin Towers, including the 9 gauge steel wire, played a crucial role in the buildings’ structural integrity and overall design. The use of high-strength, low-alloy steel like ASTM A36, combined with the thickness of 9 gauge steel wire, helped to ensure that the Twin Towers were able to withstand the immense weight and stress placed upon them. The diameter of 9 gauge steel wire is just one example of the many factors that go into the construction of tall buildings and other structures.