Table of Contents

Welding Techniques for Carbon Steel Pipe

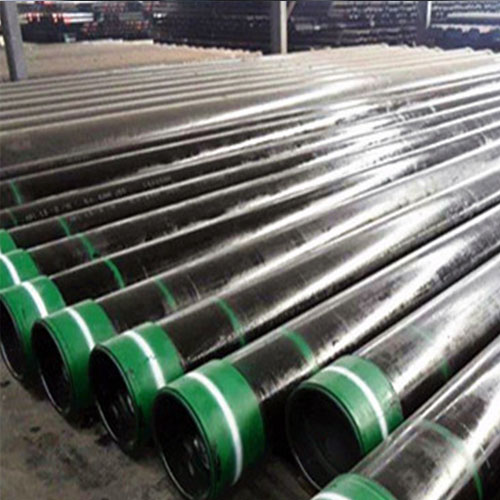

Welding techniques for carbon steel pipe are essential in the oil and gas drilling industry. Carbon Steel Pipes are commonly used in this industry due to their durability and strength. Welding is a critical process that joins two pieces of metal together to create a strong and reliable connection. There are several welding techniques that can be used for carbon steel pipes, each with its own advantages and disadvantages.

One of the most common welding techniques for carbon steel pipes is shielded metal arc welding (SMAW), also known as stick welding. This process involves using a flux-coated electrode to create an arc between the electrode and the workpiece. The heat generated by the arc melts the base metal and the electrode, creating a weld pool that solidifies to form a strong bond. SMAW is a versatile and cost-effective welding technique that can be used in various positions and environments.

Another popular welding technique for carbon steel pipes is gas metal arc welding (GMAW), also known as MIG welding. This process uses a continuous wire electrode and a shielding gas to protect the weld pool from atmospheric contamination. GMAW is a fast and efficient welding technique that produces high-quality welds with minimal spatter. It is commonly used in industrial applications where speed and precision are essential.

Flux-cored arc welding (FCAW) is another welding technique that is commonly used for carbon steel pipes. This process uses a tubular wire electrode with a flux core that provides a shielding gas to protect the weld pool. FCAW is a versatile welding technique that can be used in various positions and environments. It is ideal for welding thick materials and can produce high-quality welds with minimal distortion.

In addition to these welding techniques, there are also specialized processes that can be used for carbon steel pipes. Submerged arc welding (Saw) is a high-productivity welding technique that uses a granular flux to protect the weld pool. This process is ideal for welding thick materials and can produce high-quality welds with minimal spatter. SAW is commonly used in the oil and gas drilling industry for welding large-diameter pipes.

When welding carbon steel pipes, it is essential to follow proper Safety procedures and guidelines. Welders should wear Protective Gear, such as gloves, goggles, and Helmets, to protect themselves from sparks and fumes. It is also important to ensure that the work area is well-ventilated to prevent exposure to harmful gases and fumes.

In conclusion, welding techniques for carbon steel pipes are essential in the oil and gas drilling industry. There are several welding techniques that can be used for carbon steel pipes, each with its own advantages and disadvantages. It is important to choose the right welding technique based on the specific requirements of the project. By following proper safety procedures and guidelines, welders can create strong and reliable welds that meet the highest industry standards.