Table of Contents

Benefits of Using Liquid Stripping-resistant Additive in Asphalt Mixtures

Asphalt mixtures are commonly used in road construction due to their durability and ability to withstand heavy traffic loads. However, one of the main challenges faced by asphalt pavements is stripping, which occurs when the bond between the asphalt binder and the aggregate is weakened, leading to pavement failure. To combat this issue, liquid stripping-resistant additives are often used in asphalt mixtures to improve the adhesion between the asphalt binder and the aggregate.

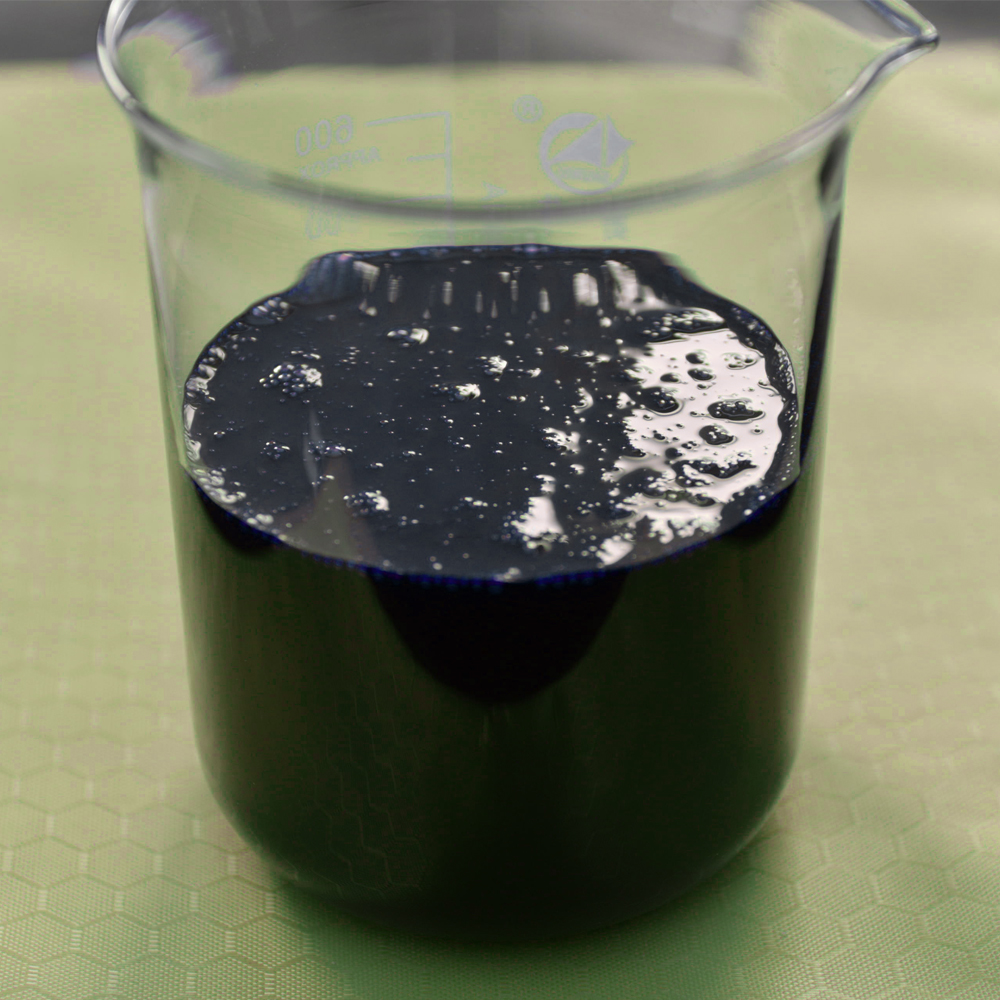

Liquid stripping-resistant additives, also known as asphalt anti-strip agents, are chemical compounds that are added to asphalt mixtures to enhance the adhesion between the asphalt binder and the aggregate. These additives work by modifying the surface chemistry of the aggregate, making it more compatible with the asphalt binder. This improved adhesion helps to prevent the stripping of the asphalt binder from the aggregate, thereby increasing the durability and longevity of the pavement.

One of the main benefits of using liquid stripping-resistant additives in asphalt mixtures is improved moisture resistance. Moisture is one of the main causes of stripping in asphalt pavements, as water can weaken the bond between the asphalt binder and the aggregate. By using a liquid stripping-resistant additive, the adhesion between the asphalt binder and the aggregate is enhanced, making the pavement more resistant to moisture damage. This helps to prevent the formation of cracks and potholes, prolonging the life of the pavement.

Another benefit of using liquid stripping-resistant additives is increased rutting resistance. Rutting, or the formation of depressions in the pavement due to repeated traffic loading, is a common issue in asphalt pavements. By improving the adhesion between the asphalt binder and the aggregate, liquid stripping-resistant additives help to distribute the load more evenly across the pavement, reducing the risk of rutting. This results in a smoother and more durable pavement surface that can withstand heavy traffic loads.

In addition to improving moisture and rutting resistance, liquid stripping-resistant additives also help to enhance the overall performance of the asphalt mixture. By increasing the adhesion between the asphalt binder and the aggregate, these additives improve the cohesion of the mixture, making it more resistant to cracking and fatigue. This results in a stronger and more durable pavement that requires less maintenance over time.

| Serial Number | Product Name |

| 1 | Stripping-resistant additive |

Overall, the use of liquid stripping-resistant additives in asphalt mixtures offers a range of benefits that contribute to the longevity and performance of the pavement. By improving moisture resistance, rutting resistance, and overall performance, these additives help to create a more durable and sustainable pavement that can withstand the challenges of heavy traffic and harsh weather conditions. As such, liquid stripping-resistant additives are an essential component of modern asphalt mixtures, helping to ensure the long-term success of road construction projects.