Table of Contents

Advantages of Using Traction Steel Wire Rope in Industrial Applications

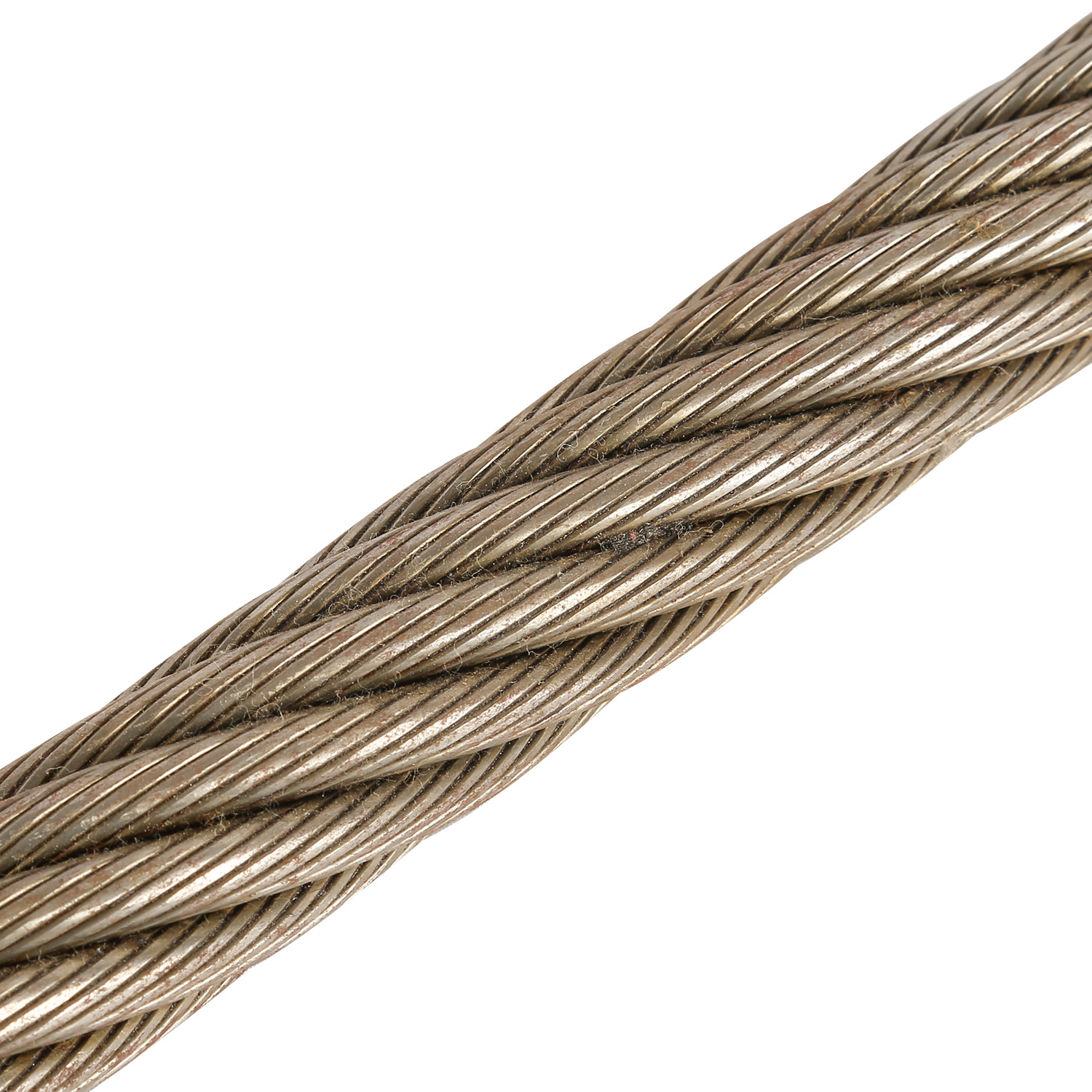

Traction steel wire rope is a crucial component in many industrial applications, providing strength and durability for a variety of tasks. One of the key advantages of using traction steel wire rope is its ability to withstand heavy loads and harsh conditions. This makes it an ideal choice for industries such as construction, mining, and transportation, where reliability and Safety are paramount.

The high tensile strength of traction steel wire rope allows it to support heavy loads without stretching or breaking. This is essential in applications where the safety of workers and equipment is at stake. Traction steel wire rope is also resistant to corrosion, making it suitable for use in outdoor environments where exposure to moisture and other elements is common.

In addition to its strength and durability, traction steel wire rope is also flexible and easy to work with. This makes it a versatile option for a wide range of applications, from lifting and hoisting to towing and anchoring. Traction steel wire rope can be easily cut to size and spliced together to create custom lengths, making it a cost-effective solution for many industrial tasks.

Another advantage of using traction steel wire rope is its long lifespan. When properly maintained and inspected regularly, traction steel wire rope can last for years, providing reliable performance and peace of mind for industrial operators. This longevity helps to reduce downtime and maintenance costs, making traction steel wire rope a smart investment for businesses looking to improve efficiency and productivity.

Malleable steel Wire Rope Clips are often used in conjunction with traction steel wire rope to secure and fasten the rope in place. These clips are designed to grip the wire rope tightly, preventing slippage and ensuring a secure connection. Malleable steel wire rope clips are easy to install and can be adjusted as needed, making them a convenient and reliable option for industrial applications.

In conclusion, the advantages of using traction steel wire rope in industrial applications are clear. Its strength, durability, flexibility, and longevity make it a versatile and cost-effective solution for a wide range of tasks. When paired with malleable steel wire rope clips, traction steel wire rope provides a secure and reliable connection that can withstand heavy loads and harsh conditions. For businesses looking to improve efficiency, safety, and productivity, traction steel wire rope is a smart choice that delivers results.

How to Properly Install and Maintain Malleable Steel Wire Rope Clips

Steel wire ropes are essential components in various industries, providing strength and durability for lifting, towing, and securing heavy loads. To ensure the safety and efficiency of these wire ropes, proper installation and maintenance are crucial. Malleable steel wire rope clips are commonly used to secure the loose end of a wire rope to the standing part, creating a loop or eyelet. In this article, we will discuss how to properly install and maintain malleable steel wire rope clips to maximize their effectiveness and longevity.

When installing malleable steel wire rope clips, it is important to follow a few key steps to ensure a secure and reliable connection. First, select the appropriate size of wire rope clip for the diameter of the wire rope being used. It is recommended to use a clip that is at least the same size as the wire rope to ensure a proper fit. Next, place the wire rope clip over the end of the wire rope, making sure that the saddle of the clip is on the live end of the rope.

Once the clip is in position, tighten the Nuts evenly on the U-bolt using a Wrench. It is important to tighten the nuts to the manufacturer’s recommended torque specifications to ensure a secure grip on the wire rope. Over-tightening the nuts can cause damage to the wire rope, while under-tightening can result in slippage and potential failure of the connection. After the nuts are tightened, inspect the installation to ensure that the wire rope is properly seated in the saddle of the clip and that the nuts are secure.

Regular maintenance of malleable steel wire rope clips is essential to ensure their continued effectiveness and safety. Inspect the clips regularly for signs of wear, corrosion, or damage. If any of these issues are present, the clip should be replaced immediately to prevent failure of the connection. In addition, check the tightness of the nuts periodically to ensure that they have not loosened over time. If any nuts are found to be loose, tighten them to the manufacturer’s recommended torque specifications.

In environments where the wire rope is exposed to harsh conditions, such as saltwater or Chemicals, more frequent inspections and maintenance may be necessary. Cleaning the wire rope clips regularly with a wire brush and applying a rust-inhibiting lubricant can help prevent corrosion and extend the life of the clips. It is also important to store wire rope clips in a dry, clean Environment when not in use to prevent rust and deterioration.

Proper installation and maintenance of malleable steel wire rope clips are essential for ensuring the safety and reliability of wire rope connections. By following the steps outlined in this article and conducting regular inspections and maintenance, you can maximize the effectiveness and longevity of your wire rope clips. Remember to always consult the manufacturer’s guidelines and recommendations when installing and maintaining malleable steel wire rope clips to ensure proper usage and safety.