Table of Contents

Benefits of Using Liquid Anti-Strip Additives in Asphalt Mixtures

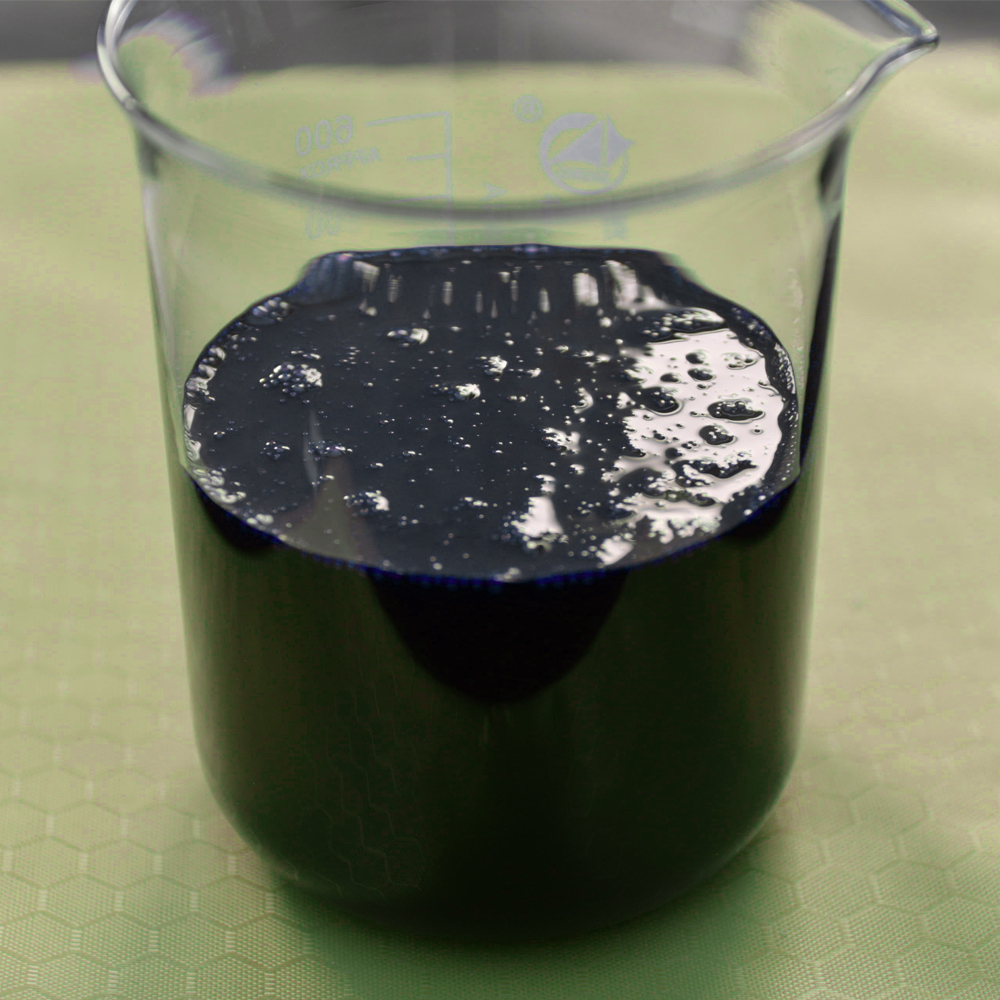

Liquid anti-strip additives are a crucial component in asphalt mixtures, as they help prevent moisture damage and improve the overall performance of the pavement. These additives work by enhancing the adhesion between the asphalt binder and the aggregate, ensuring that the mixture remains intact and durable over time. In this article, we will explore the benefits of using liquid anti-strip additives in asphalt mixtures and why they are essential for maintaining the quality and longevity of road surfaces.

One of the primary advantages of using liquid anti-strip additives is their ability to improve the resistance of asphalt mixtures to moisture damage. When water infiltrates the pavement, it can weaken the bond between the asphalt binder and the aggregate, leading to stripping and eventual pavement failure. By incorporating liquid anti-strip additives into the mixture, the adhesion between the binder and aggregate is significantly enhanced, reducing the likelihood of moisture damage and increasing the lifespan of the pavement.

Furthermore, liquid anti-strip additives can also improve the workability of asphalt mixtures during construction. These additives help reduce the viscosity of the binder, making it easier to mix and compact the asphalt mixture. This results in a more uniform and dense pavement structure, which is essential for ensuring the durability and longevity of the road surface. Additionally, the improved workability provided by liquid anti-strip additives can help reduce construction time and costs, making them a cost-effective solution for road construction projects.

Another benefit of using liquid anti-strip additives is their ability to enhance the overall performance of the pavement. By improving the adhesion between the binder and aggregate, these additives help increase the resistance of the pavement to rutting, cracking, and other forms of distress. This results in a smoother and more durable road surface that can withstand heavy traffic loads and harsh environmental conditions. Additionally, the enhanced performance provided by liquid anti-strip additives can help reduce maintenance and repair costs, making them a valuable investment for road agencies and contractors.

In addition to their performance benefits, liquid anti-strip additives are also environmentally friendly. These additives are typically made from renewable resources and do not contain harmful Chemicals or volatile organic compounds. This makes them a sustainable and eco-friendly option for road construction projects, helping to reduce the environmental impact of pavement construction and maintenance. By using liquid anti-strip additives, road agencies and contractors can contribute to a more sustainable and greener infrastructure that benefits both the Environment and the community.

Overall, the benefits of using liquid anti-strip additives in asphalt mixtures are clear. From improving resistance to moisture damage and enhancing workability to enhancing pavement performance and reducing environmental impact, these additives offer a wide range of advantages for road construction projects. By incorporating liquid anti-strip additives into asphalt mixtures, road agencies and contractors can ensure the quality and longevity of road surfaces, leading to safer and more durable infrastructure for years to come.

How to Properly Apply Liquid Anti-Strip Additives for Maximum Effectiveness

Liquid anti-strip additives are an essential component in asphalt pavement construction and maintenance. These additives are designed to improve the adhesion between asphalt binder and aggregate, ultimately enhancing the overall performance and durability of the pavement. However, in order to achieve maximum effectiveness, it is crucial to properly apply liquid anti-strip additives during the asphalt mixing process.

One of the key factors to consider when applying liquid anti-strip additives is the dosage. It is important to follow the manufacturer’s recommendations for the correct dosage of the additive based on the type of asphalt binder being used and the specific conditions of the project. Applying too little of the additive may not provide the desired level of adhesion improvement, while applying too much can Lead to negative effects on the performance of the asphalt mixture.

In addition to the correct dosage, the timing of adding the liquid anti-strip additive is also critical. The additive should be introduced into the asphalt mixture at the appropriate stage of the mixing process to ensure proper dispersion and interaction with the binder and aggregate. Typically, liquid anti-strip additives are added during the mixing of the asphalt binder and aggregate, either directly into the mixing Drum or through a separate injection system.

Proper mixing is essential to ensure that the liquid anti-strip additive is evenly distributed throughout the asphalt mixture. Inadequate mixing can result in uneven distribution of the additive, leading to inconsistent adhesion between the binder and aggregate. To achieve optimal mixing, it is important to follow the mixing time and temperature recommendations provided by the additive manufacturer.

After the asphalt mixture has been properly mixed with the liquid anti-strip additive, it is crucial to conduct quality control testing to verify the effectiveness of the additive. Testing methods such as the boiling water test or the Tensile Strength Ratio (TSR) test can be used to assess the adhesion properties of the asphalt mixture and determine if the additive has been applied correctly.

Proper storage and handling of liquid anti-strip additives are also important considerations to ensure their effectiveness. Additives should be stored in a cool, dry place away from direct sunlight and extreme temperatures. It is also important to follow proper Safety precautions when handling and applying liquid anti-strip additives to prevent exposure to skin or eyes.

In conclusion, liquid anti-strip additives play a crucial role in improving the adhesion between asphalt binder and aggregate in pavement construction. By following the correct dosage, timing, mixing, testing, and storage procedures, contractors can ensure that these additives are applied properly for maximum effectiveness. Proper application of liquid anti-strip additives can result in enhanced pavement performance, increased durability, and reduced maintenance costs in the long run.

| Nr. | Products |

| 1 | asphalt Stripping-resistant agent |