Table of Contents

Benefits of Using Asphalt Polyester Fiber in Roadway Engineering

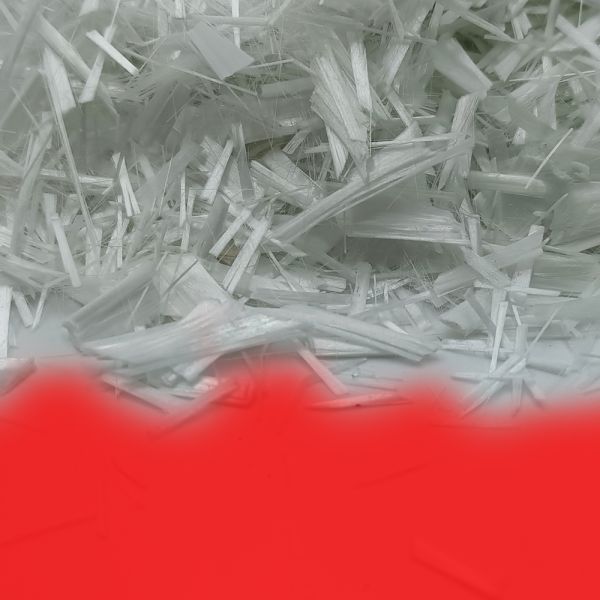

Asphalt polyester fiber is a material that has been gaining popularity in roadway engineering due to its numerous benefits. This synthetic fiber is made from polyester, a type of plastic that is known for its durability and strength. When added to asphalt mixtures, asphalt polyester fiber can improve the performance and longevity of roadways in various ways.

One of the key benefits of using asphalt polyester fiber in roadway engineering is its ability to enhance the tensile strength of asphalt mixtures. Tensile strength is the ability of a material to resist breaking under tension, and it is an important factor in determining the durability of roadways. By adding polyester fiber to asphalt mixtures, engineers can increase the tensile strength of the pavement, making it more resistant to cracking and rutting.

In addition to improving tensile strength, asphalt polyester fiber can also help reduce the occurrence of reflective cracking in roadways. Reflective cracking occurs when cracks in the underlying pavement are reflected through the surface layer, leading to premature pavement failure. By adding polyester fiber to asphalt mixtures, engineers can create a more flexible and crack-resistant pavement that is less prone to reflective cracking.

Another benefit of using asphalt polyester fiber in roadway engineering is its ability to improve the fatigue resistance of pavements. Fatigue resistance is the ability of a material to withstand repeated loading and unloading without experiencing permanent deformation. By adding polyester fiber to asphalt mixtures, engineers can enhance the fatigue resistance of the pavement, making it more durable and long-lasting.

Furthermore, asphalt polyester fiber can help improve the overall performance of roadways in terms of ride quality and Safety. By creating a more durable and crack-resistant pavement, polyester fiber can help reduce maintenance costs and prolong the lifespan of roadways. Additionally, the improved performance of roadways can enhance the driving experience for motorists, leading to smoother and safer roads.

In conclusion, asphalt polyester fiber offers numerous benefits for roadway engineering. From enhancing tensile strength and reducing reflective cracking to improving fatigue resistance and overall performance, polyester fiber can help create more durable and long-lasting roadways. By incorporating asphalt polyester fiber into asphalt mixtures, engineers can build high-quality pavements that provide a smoother and safer driving experience for motorists. As the demand for sustainable and cost-effective infrastructure solutions continues to grow, asphalt polyester fiber is poised to play a key role in the future of roadway engineering.

How Asphalt Polyester Fiber Enhances Durability and Performance of Road Surfaces

Asphalt polyester fiber is a material that has been gaining popularity in roadway engineering due to its ability to enhance the durability and performance of road surfaces. This synthetic fiber is made from a blend of asphalt and polyester, which gives it unique properties that make it ideal for use in various road construction projects.

One of the key benefits of using asphalt polyester fiber in road surfaces is its ability to improve the overall strength and durability of the pavement. The addition of polyester fibers to the asphalt mix helps to reinforce the pavement, making it more resistant to cracking, rutting, and other forms of damage that can occur over time. This increased strength and durability can help to extend the lifespan of the road surface, reducing the need for costly repairs and maintenance in the future.

In addition to enhancing the durability of road surfaces, asphalt polyester fiber can also improve the performance of the pavement. The fibers help to create a more uniform and stable pavement structure, which can reduce the occurrence of potholes, rutting, and other forms of pavement distress. This can Lead to a smoother and safer driving experience for motorists, as well as reduced wear and tear on vehicles.

Furthermore, asphalt polyester fiber can also help to improve the overall sustainability of road construction projects. By using a material that enhances the durability and performance of road surfaces, engineers can reduce the need for frequent repairs and maintenance, which can help to lower the environmental impact of road construction. Additionally, the use of asphalt polyester fiber can help to extend the lifespan of road surfaces, reducing the amount of materials that need to be used in future construction projects.

| Serial Number | Article Name |

| 1 | for road use Artificial fibers |

Overall, asphalt polyester fiber is a versatile material that offers a wide range of benefits for roadway engineering. Its ability to enhance the durability and performance of road surfaces can help to create safer, smoother, and more sustainable roadways for motorists. By incorporating this innovative material into road construction projects, engineers can improve the quality and longevity of road surfaces, ultimately leading to a more efficient and cost-effective transportation infrastructure.

In conclusion, asphalt polyester fiber is a valuable material that can significantly enhance the durability and performance of road surfaces. Its unique properties make it an ideal choice for use in roadway engineering projects, where strength, stability, and sustainability are key considerations. By incorporating asphalt polyester fiber into road construction projects, engineers can create road surfaces that are more resistant to damage, smoother to drive on, and more environmentally friendly. This innovative material is helping to shape the future of road construction, paving the way for safer, more sustainable transportation infrastructure.