Table of Contents

Exploring the Production Process of Cheap Low Smoke Halogen-Free Network Cables

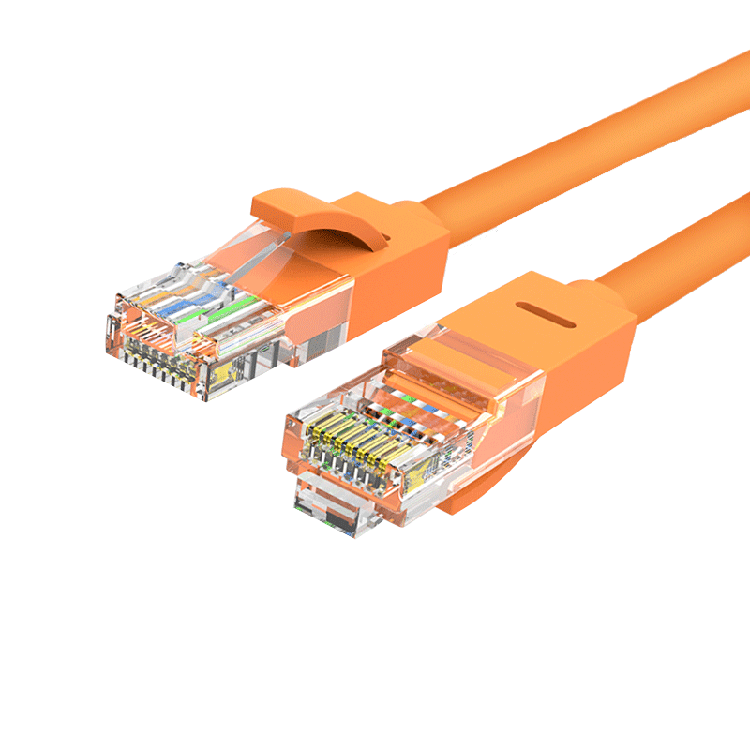

In the realm of network cables, the demand for cheap low smoke halogen-free (LSHF) cables is on the rise. These cables are lauded for their Safety features, particularly in the event of a fire, where they emit minimal smoke and no toxic halogen gases. This article aims to explore the production process of these cost-effective and environmentally friendly network cables.

| Serial Number | Product |

| 1 | patch cord wiring |

The production of cheap LSHF network cables begins with the selection of high-quality raw materials. The primary material used is a thermoplastic compound that is halogen-free, flame retardant, and emits low smoke when exposed to high temperatures. This compound is typically made from a blend of polyolefin and a special type of filler that aids in reducing the emission of smoke and toxic gases.

The next step in the production process involves the extrusion of the halogen-free compound. This is achieved by heating the compound until it becomes pliable, then forcing it through a die to form the insulation layer of the cable. The extrusion process is meticulously controlled to ensure the insulation layer is uniform and free from defects, which could compromise the cable’s performance.

Once the insulation layer is formed, the cable undergoes a process known as cabling. This involves twisting together different insulated conductors to form the cable core. The number of conductors twisted together depends on the specific requirements of the network cable. For instance, an Ethernet cable typically consists of four pairs of twisted conductors.

After the cabling process, a protective jacket is applied over the cable core. This jacket is also made from the low smoke halogen-free compound, providing an additional layer of protection. The jacket not only shields the cable from physical damage but also enhances its fire-resistant properties.

| Serial Number | Product |

| 1 | Communication Cable |

The final stage in the production process is quality control. Each batch of cables is subjected to rigorous testing to ensure they meet the required safety and performance standards. These tests include flame retardancy tests, smoke density tests, and halogen acid gas tests. Only those cables that pass these stringent tests are deemed fit for the market.

The production process of cheap LSHF network cables is a testament to the advancements in cable technology. It combines the use of innovative materials with precise manufacturing techniques to produce cables that are not only cost-effective but also environmentally friendly and safe to use.

However, it’s important to note that while these cables are cheaper than their counterparts, this does not mean they compromise on quality. The term ‘cheap’ refers to the cost-effectiveness of these cables, which is achieved through efficient production processes and the use of affordable, high-quality materials.

In conclusion, the production of cheap low smoke halogen-free network cables is a complex process that requires a high level of precision and quality control. It involves the use of innovative, environmentally friendly materials and advanced manufacturing techniques. The end result is a product that is safe, reliable, and cost-effective, making it an ideal choice for various networking applications.

Understanding the Benefits of Using Low Smoke Halogen-Free Network Cables from Affordable Factories

In the realm of network cabling, the importance of safety and environmental consciousness cannot be overstated. One of the most significant advancements in this field is the development of low smoke halogen-free (LSHF) network cables. These cables, produced by affordable factories, offer a myriad of benefits that make them an excellent choice for various applications.

LSHF network cables are designed to emit minimal smoke and no toxic halogen gases when exposed to high temperatures or fire. This characteristic is particularly crucial in densely populated settings such as Office Buildings, hospitals, and schools, where the safety of individuals is paramount. In the unfortunate event of a fire, traditional cables can release dense smoke and toxic gases, including chlorine, fluorine, and bromine, which can cause harm to people and impede firefighting efforts. On the other hand, LSHF cables produce less smoke and no harmful gases, significantly reducing the risk to human health and visibility during evacuation.

Moreover, LSHF network cables are environmentally friendly. The absence of halogens in these cables means that they do not release harmful substances into the Environment during their production, use, or disposal. This feature aligns with the growing global emphasis on sustainability and the need to reduce the environmental impact of our activities. By choosing LSHF cables, businesses can contribute to environmental conservation efforts and potentially enhance their reputation as responsible corporate citizens.

Despite these significant advantages, one might assume that LSHF network cables come with a hefty price tag. However, this is not the case. Thanks to advancements in manufacturing technology and economies of scale, factories can produce these cables at affordable prices. These cost savings are then passed on to the consumer, making LSHF cables a cost-effective choice for businesses of all sizes.

Furthermore, these affordable factories do not compromise on the quality of LSHF network cables. They adhere to stringent manufacturing standards to ensure that the cables are durable, reliable, and perform at optimal Levels. This commitment to quality ensures that businesses get value for their money and can rely on their network infrastructure for seamless operations.

In addition to their safety, environmental, and cost benefits, LSHF network cables also offer excellent performance. They are designed to support high-speed data transmission, making them suitable for modern networks that handle large volumes of data. This feature ensures that businesses can meet their communication needs effectively and efficiently.

In conclusion, low smoke halogen-free network cables from affordable factories offer a compelling combination of safety, environmental consciousness, cost-effectiveness, and performance. They are a testament to how innovation can drive improvements in safety and sustainability while delivering value for money. As businesses and individuals continue to seek solutions that align with their safety and environmental goals, LSHF network cables are poised to become an increasingly popular choice. Therefore, when planning your next network infrastructure upgrade or installation, consider the benefits of using low smoke halogen-free network cables.