Table of Contents

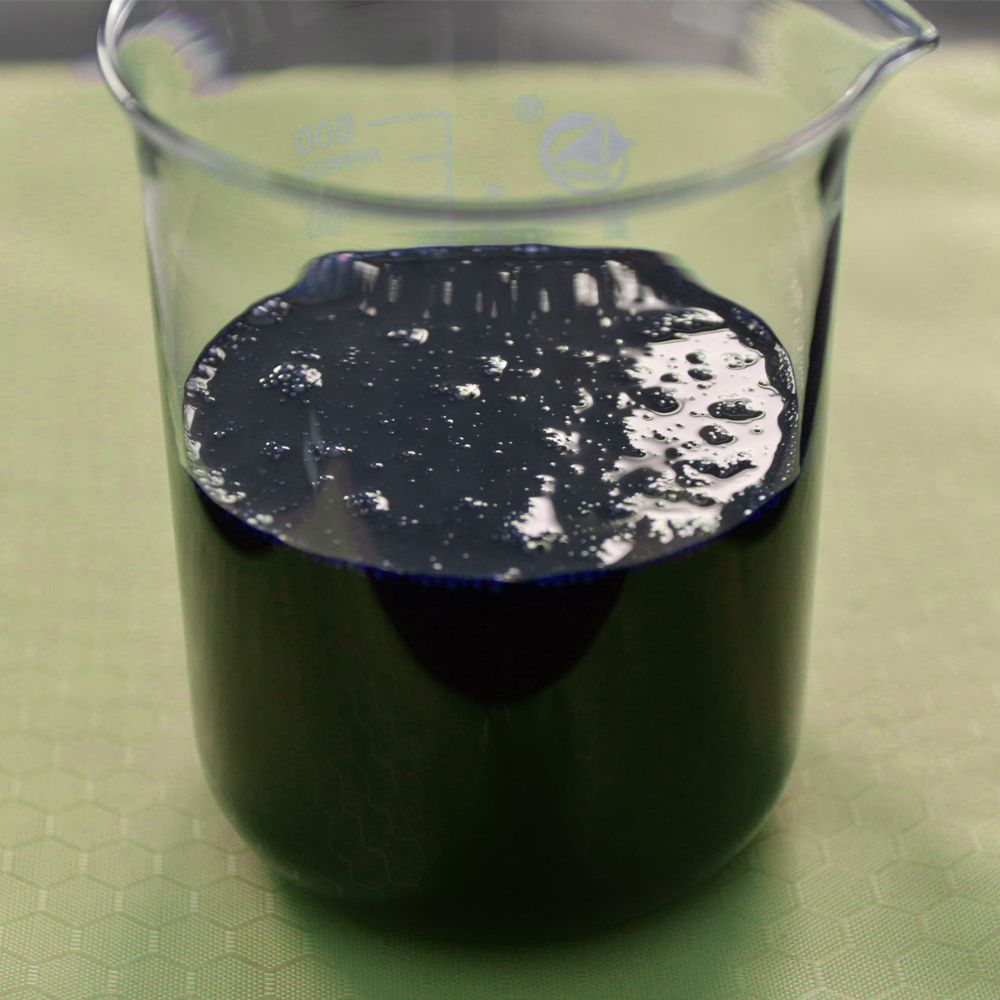

The Importance of Bitumen Stripping Resistance Agents in Factory Production

Bitumen stripping resistance agents play a crucial role in the production process of factories that deal with bitumen-based products. These agents are additives that are used to improve the adhesion of bitumen to aggregates, preventing the stripping of the bitumen from the surface of the aggregates. This is important because stripping can Lead to premature pavement failure, reducing the lifespan of the road and increasing maintenance costs.

| Serial Number | Item |

| 1 | Bitumen bonding agent agent |

One of the key reasons why bitumen stripping resistance agents are essential in factory production is that they help to ensure the durability and longevity of the final product. When bitumen does not adhere properly to the aggregates, it can lead to the formation of voids and moisture infiltration, which can weaken the pavement structure over time. By using stripping resistance agents, factories can enhance the bond between the bitumen and aggregates, creating a more durable and long-lasting pavement.

In addition to improving the durability of the pavement, bitumen stripping resistance agents also help to enhance the overall performance of the road. When bitumen is stripped from the aggregates, it can lead to a loss of skid resistance, making the road surface slippery and dangerous for drivers. By using stripping resistance agents, factories can ensure that the pavement maintains its skid resistance, providing a safer driving experience for motorists.

Furthermore, bitumen stripping resistance agents can also help to reduce maintenance costs for road authorities. When pavement fails prematurely due to stripping, it requires costly repairs and rehabilitation work to restore its integrity. By using stripping resistance agents during the production process, factories can help to prevent premature pavement failure, reducing the need for expensive maintenance and repairs in the future.

It is important for factories to carefully select the right type of bitumen stripping resistance agent for their production process. There are various types of agents available on the market, each with its own unique properties and benefits. Factors such as the type of aggregates being used, the climate conditions, and the traffic volume on the road should be taken into consideration when choosing a stripping resistance agent.

In addition to selecting the right type of agent, it is also important for factories to follow proper mixing and application procedures to ensure the effectiveness of the stripping resistance agent. Improper mixing or application can lead to uneven distribution of the agent, reducing its effectiveness in preventing stripping. By following best practices in mixing and application, factories can maximize the performance of the stripping resistance agent and ensure the quality of the final product.

In conclusion, bitumen stripping resistance agents play a vital role in the production process of factories that deal with bitumen-based products. These agents help to improve the adhesion of bitumen to aggregates, preventing the stripping of the bitumen from the surface of the aggregates. By using stripping resistance agents, factories can enhance the durability, performance, and Safety of the pavement, while also reducing maintenance costs for road authorities. It is important for factories to carefully select the right type of agent and follow proper mixing and application procedures to ensure the effectiveness of the stripping resistance agent in their production process.