Table of Contents

Basalt Chopped Fiber

Basalt fiber is a versatile material that has been gaining popularity in the construction industry for its strength and durability. One of the applications of basalt fiber is in flexible asphalt pavements, where it can enhance the performance and longevity of the pavement.

| Nr. | Products |

| 1 | Basalt road reinforcement fiber |

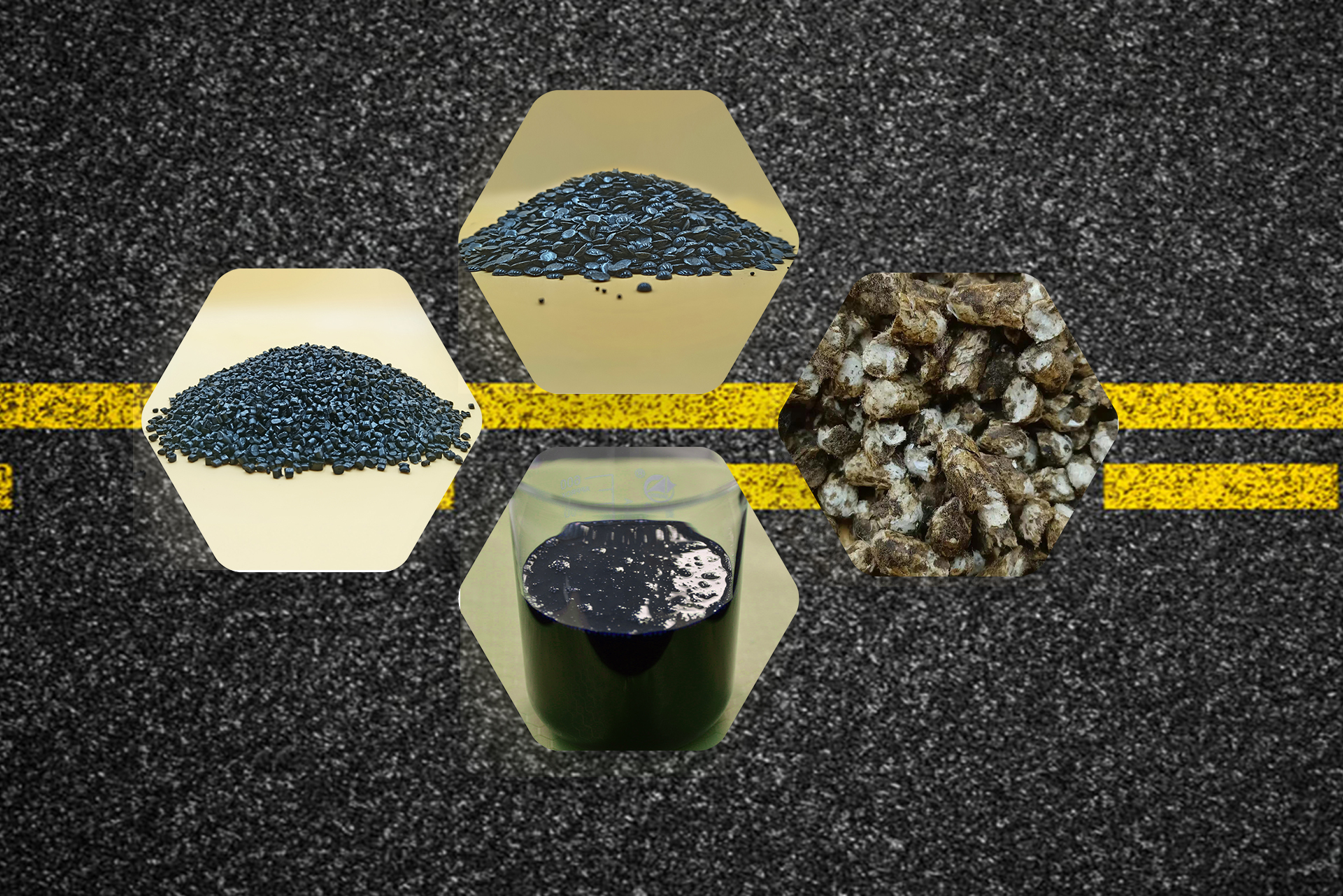

Basalt chopped fiber is a form of basalt fiber that is commonly used in asphalt pavements. It is made by chopping basalt fibers into short lengths, which are then mixed into the asphalt mixture. The addition of basalt chopped fiber can improve the tensile strength and fatigue resistance of the pavement, making it more durable and resistant to cracking.

One of the key benefits of using basalt chopped fiber in asphalt pavements is its ability to enhance the flexibility of the pavement. Flexible pavements are designed to withstand the stresses and strains caused by traffic loads, temperature fluctuations, and other environmental factors. By adding basalt chopped fiber to the asphalt mixture, engineers can create a more flexible pavement that can better accommodate these stresses without cracking or deteriorating.

In addition to improving flexibility, basalt chopped fiber can also help to reduce rutting and rutting-related issues in asphalt pavements. Rutting is a common problem in asphalt pavements, where the surface of the pavement becomes deformed and worn Down by repeated traffic loads. By reinforcing the asphalt mixture with basalt chopped fiber, engineers can increase the resistance of the pavement to rutting, prolonging its service life and reducing maintenance costs.

Basalt chopped fiber can also improve the overall performance of asphalt pavements in terms of durability and longevity. The addition of basalt fiber can increase the tensile strength of the pavement, making it more resistant to cracking and fatigue. This can extend the service life of the pavement and reduce the need for frequent repairs and maintenance.

Another advantage of using basalt chopped fiber in asphalt pavements is its environmental sustainability. Basalt fiber is a natural material that is derived from volcanic rock, making it a renewable and eco-friendly alternative to traditional reinforcement materials. By using basalt chopped fiber in asphalt pavements, engineers can reduce the environmental impact of construction projects and contribute to a more sustainable built Environment.

Overall, basalt chopped fiber is a valuable material for enhancing the performance and longevity of flexible asphalt pavements. Its ability to improve flexibility, reduce rutting, increase durability, and promote environmental sustainability make it a preferred choice for engineers and contractors looking to optimize the performance of their pavement projects. By incorporating basalt chopped fiber into asphalt mixtures, construction professionals can create pavements that are stronger, more resilient, and more sustainable in the long run.

Basalt Chopped Fiber Yarn

Basalt fiber is a versatile material that has been gaining popularity in the construction industry for its strength and durability. One of the applications of basalt fiber is in flexible asphalt pavements, where it can enhance the performance and longevity of the pavement. Basalt chopped fiber yarn is a form of basalt fiber that is commonly used in asphalt pavements to improve their flexibility and resistance to cracking.

Basalt chopped fiber yarn is made by chopping basalt fibers into short lengths and then twisting them together to form a yarn. This yarn can be easily mixed into asphalt mixtures to reinforce the pavement and improve its mechanical properties. The use of basalt chopped fiber yarn in asphalt pavements has been shown to increase the tensile strength and fatigue resistance of the pavement, making it more durable and long-lasting.

One of the key benefits of using basalt chopped fiber yarn in asphalt pavements is its ability to improve the flexibility of the pavement. Flexible pavements are designed to withstand the stresses and strains caused by traffic loads and temperature fluctuations without cracking or deteriorating. By adding basalt chopped fiber yarn to the asphalt mixture, the pavement becomes more flexible and better able to accommodate these stresses, reducing the likelihood of cracking and extending the life of the pavement.

In addition to improving flexibility, basalt chopped fiber yarn also enhances the resistance of asphalt pavements to rutting and fatigue. Rutting is a common issue in asphalt pavements where the surface becomes deformed and develops ruts due to repeated traffic loading. By reinforcing the pavement with basalt chopped fiber yarn, the asphalt mixture becomes more resistant to rutting, maintaining a smooth and even surface for longer periods.

Furthermore, basalt chopped fiber yarn can also improve the overall performance of asphalt pavements in terms of durability and sustainability. The use of basalt fiber as a reinforcement material reduces the need for traditional materials such as steel or fiberglass, which are more energy-intensive to produce and have a higher carbon footprint. Basalt fiber is a natural material that is abundant and environmentally friendly, making it a sustainable choice for construction projects.

Overall, basalt chopped fiber yarn is a valuable addition to asphalt pavements, offering a range of benefits including improved flexibility, resistance to cracking, rutting, and fatigue, as well as enhanced durability and sustainability. By incorporating basalt fiber into asphalt mixtures, engineers and contractors can create pavements that are stronger, longer-lasting, and more environmentally friendly. As the construction industry continues to seek innovative solutions for infrastructure challenges, basalt fiber is poised to play a key role in the development of flexible and sustainable asphalt pavements.