Table of Contents

Strength and Durability Requirements for Steel Wire Rope Specifications PDF

Steel wire rope is a critical component in various industries, including construction, mining, and transportation. It is essential to understand the specifications of steel wire rope to ensure its strength and durability in different applications. In this article, we will delve into the requirements for steel wire rope specifications in PDF format.

Steel wire rope specifications in PDF format provide detailed information about the construction, materials, and performance characteristics of the rope. These specifications are crucial for ensuring that the rope meets the necessary strength and durability requirements for its intended use. When selecting a steel wire rope, it is essential to refer to the manufacturer’s specifications to ensure that it is suitable for the specific application.

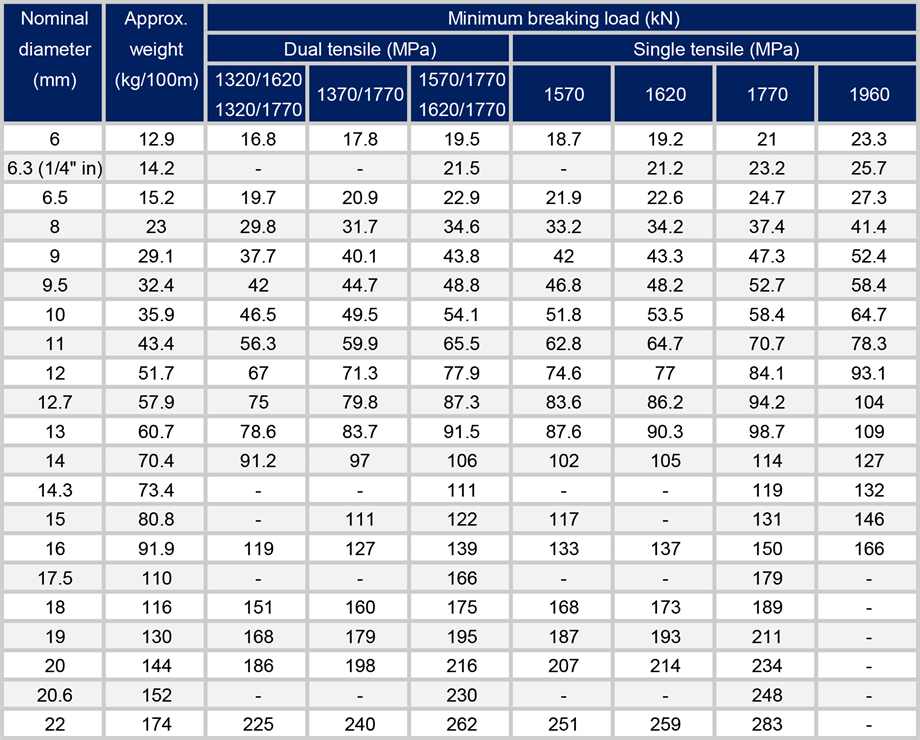

One of the key requirements for steel wire rope specifications is the breaking strength. This is the maximum load that the rope can withstand before it fails. The breaking strength of a steel wire rope is determined by factors such as the diameter of the rope, the number of strands, and the type of core. The breaking strength is typically expressed in kilonewtons (kN) or pounds (lbs) and is an important consideration when selecting a rope for lifting or pulling heavy loads.

In addition to breaking strength, steel wire rope specifications also include information about the fatigue resistance of the rope. Fatigue is a common cause of failure in steel wire ropes, especially in applications where the rope is subjected to repeated bending and flexing. The specifications will outline the number of cycles that the rope can withstand before it begins to show signs of fatigue, as well as any special treatments or coatings that can improve the fatigue resistance of the rope.

Another important consideration in steel wire rope specifications is the corrosion resistance of the rope. Steel wire ropes are often used in harsh environments where they are exposed to moisture, Chemicals, and other corrosive agents. The specifications will detail the type of coating or treatment applied to the rope to protect it from corrosion, as well as any maintenance requirements to ensure the longevity of the rope.

Furthermore, steel wire rope specifications in PDF format will provide information about the flexibility and abrasion resistance of the rope. These characteristics are crucial for ensuring that the rope can bend and flex without breaking, as well as withstand wear and tear from friction and contact with rough surfaces. The specifications will outline the minimum bend radius of the rope, as well as any special coatings or treatments that improve its abrasion resistance.

In conclusion, steel wire rope specifications in PDF format are essential for ensuring the strength and durability of the rope in various applications. By referring to the manufacturer’s specifications, users can select the right rope for their specific needs and ensure that it meets the necessary requirements for Safety and performance. Whether used for lifting heavy loads, securing equipment, or towing vehicles, steel wire rope specifications play a crucial role in ensuring the reliability and longevity of the rope.

Compliance with Industry Standards and Regulations in Steel Wire Rope Specifications PDF

Steel wire ropes are essential components in various industries, including construction, mining, and transportation. These ropes are used for lifting heavy loads, securing structures, and providing support in various applications. To ensure the safety and reliability of steel wire ropes, it is crucial to adhere to industry standards and regulations outlined in the steel wire rope specifications PDF.

One of the key aspects of compliance with industry standards is the material used in manufacturing steel wire ropes. The specifications PDF provides detailed information on the type of steel, the diameter of the wire, and the construction of the rope. These specifications are designed to ensure that the steel wire rope meets the required strength and durability standards for its intended use.

In addition to material specifications, the PDF also outlines requirements for the design and construction of steel wire ropes. This includes details on the number of strands, the lay of the rope, and the type of core used. By following these specifications, manufacturers can produce steel wire ropes that are capable of withstanding the stresses and strains of everyday use.

Furthermore, the steel wire rope specifications PDF includes information on testing and inspection requirements. This ensures that each batch of steel wire ropes undergoes rigorous testing to verify its strength, flexibility, and overall quality. By conducting regular inspections, manufacturers can identify any defects or weaknesses in the ropes and take corrective action before they are put into service.

Compliance with industry standards is not only important for manufacturers but also for end-users of steel wire ropes. By using ropes that meet the specifications outlined in the PDF, companies can ensure the safety of their workers and the reliability of their equipment. Non-compliance with industry standards can Lead to accidents, injuries, and costly downtime.

It is essential for companies to familiarize themselves with the steel wire rope specifications PDF and ensure that they are purchasing ropes that meet these standards. This can be achieved by working with reputable suppliers who have a track record of producing high-quality steel wire ropes that comply with industry regulations.

In conclusion, compliance with industry standards and regulations in steel wire rope specifications PDF is crucial for ensuring the safety and reliability of these essential components. By following the material specifications, design requirements, and testing procedures outlined in the PDF, manufacturers can produce high-quality steel wire ropes that meet the needs of various industries. End-users can also benefit from using ropes that comply with industry standards, as this can help prevent accidents and ensure the longevity of their equipment. By working together to uphold these standards, the industry can continue to rely on steel wire ropes for years to come.

Importance of Proper Installation and Maintenance Procedures for Steel Wire Rope Specifications PDF

Steel wire ropes are essential components in various industries, including construction, mining, and transportation. They are used for lifting heavy loads, supporting structures, and providing stability in various applications. To ensure the safety and efficiency of these wire ropes, it is crucial to follow proper installation and maintenance procedures.

Proper installation of steel wire ropes is essential to ensure their performance and longevity. Before installing a wire rope, it is important to carefully read the manufacturer’s specifications provided in the PDF document. These specifications outline the recommended procedures for handling, storing, and installing the wire rope. Following these guidelines will help prevent damage to the wire rope and ensure that it performs as intended.

When installing a steel wire rope, it is important to inspect the rope for any signs of damage or wear. Any damaged or worn sections should be replaced before installation to prevent accidents or failures. Additionally, the wire rope should be properly lubricated to reduce friction and extend its lifespan. Proper lubrication will also help prevent corrosion and rust, which can weaken the wire rope over time.

During installation, it is important to follow the recommended procedures for attaching the wire rope to its intended anchor points. Using the correct fittings and Hardware will ensure that the wire rope is securely attached and can safely support the intended load. Improper attachment can lead to failure and pose a significant safety risk.

Once the wire rope is installed, regular maintenance is essential to ensure its continued performance. The manufacturer’s specifications in the PDF document will provide guidelines for inspecting and maintaining the wire rope. Regular inspections should be conducted to check for signs of wear, corrosion, or damage. Any issues should be addressed promptly to prevent accidents or failures.

In addition to regular inspections, proper maintenance procedures should be followed to extend the lifespan of the wire rope. This may include cleaning the wire rope regularly to remove dirt and debris that can cause abrasion and wear. Proper lubrication should also be maintained to reduce friction and prevent corrosion. Following these maintenance procedures will help ensure the safety and efficiency of the wire rope.

In conclusion, proper installation and maintenance procedures are essential for ensuring the safety and performance of steel wire ropes. By following the manufacturer’s specifications provided in the PDF document, you can ensure that the wire rope is installed correctly and maintained properly. Regular inspections and maintenance will help prevent accidents and failures, extending the lifespan of the wire rope and ensuring its continued performance. Proper installation and maintenance procedures are crucial for the safety and efficiency of steel wire ropes in various industries.