Table of Contents

Benefits of Using Steel Wire Rope 5/8 for Heavy-Duty Applications

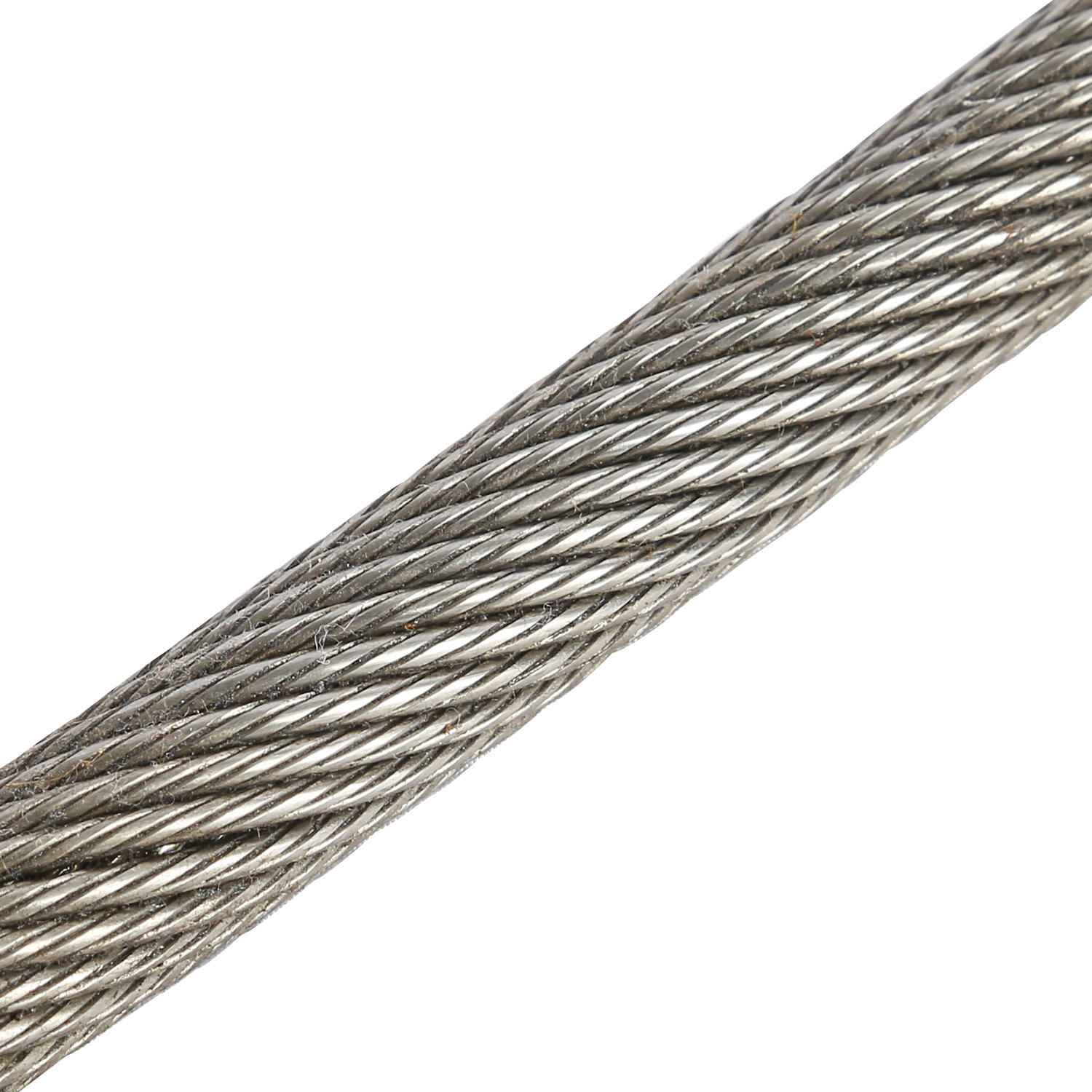

Steel wire rope 5/8 is a versatile and durable material that is commonly used in heavy-duty applications. Its strength and flexibility make it an ideal choice for a wide range of industries, including construction, mining, and transportation. In this article, we will explore the benefits of using steel wire rope 5/8 for heavy-duty applications.

One of the key advantages of steel wire rope 5/8 is its high tensile strength. This means that it can withstand heavy loads without breaking or stretching. This makes it an excellent choice for lifting and hoisting applications, where Safety and reliability are paramount. Whether you are lifting construction materials on a job site or Transporting goods in a warehouse, steel wire rope 5/8 can handle the job with ease.

In addition to its strength, steel wire rope 5/8 is also highly resistant to abrasion and corrosion. This makes it suitable for use in harsh environments where other materials may deteriorate over time. Whether you are working in a marine setting or a chemical plant, steel wire rope 5/8 will hold up to the elements and provide long-lasting performance.

Another benefit of using steel wire rope 5/8 is its flexibility. Unlike rigid materials like Chains, steel wire rope can bend and flex around corners and Obstacles without losing its strength. This makes it easier to work with in tight spaces and complex configurations. Whether you are rigging a Sailboat or securing a load on a Truck, steel wire rope 5/8 can adapt to the task at hand.

Furthermore, steel wire rope 5/8 is easy to maintain and inspect. Regular inspections can help identify any wear or damage before it becomes a safety hazard. With proper care and maintenance, steel wire rope 5/8 can last for years without needing to be replaced. This can save time and money in the long run, making it a cost-effective choice for heavy-duty applications.

In conclusion, steel wire rope 5/8 is a reliable and versatile material that is well-suited for heavy-duty applications. Its high tensile strength, resistance to abrasion and corrosion, flexibility, and ease of maintenance make it an ideal choice for industries that require durable and dependable lifting and hoisting solutions. Whether you are working in construction, mining, transportation, or any other industry that requires heavy lifting, steel wire rope 5/8 can help you get the job done safely and efficiently. Consider using steel wire rope 5/8 for your next heavy-duty application and experience the benefits for yourself.

Maintenance Tips for Extending the Lifespan of Steel Wire Rope 5/8

Steel wire rope 5/8 is a versatile and durable material commonly used in various industries for lifting, towing, and securing heavy loads. To ensure the longevity and safety of steel wire rope 5/8, proper maintenance is essential. In this article, we will discuss some maintenance tips that can help extend the lifespan of steel wire rope 5/8.

One of the most important maintenance practices for steel wire rope 5/8 is regular inspection. Inspecting the rope for signs of wear, corrosion, or damage is crucial in identifying potential issues before they escalate. Look for broken wires, kinks, or any abnormalities in the rope’s appearance. If any defects are found, the rope should be replaced immediately to prevent accidents or injuries.

In addition to visual inspections, it is also important to regularly lubricate steel wire rope 5/8. Lubrication helps reduce friction between the wires, preventing premature wear and extending the rope’s lifespan. Use a high-quality lubricant specifically designed for steel wire ropes and apply it evenly along the entire length of the rope. Be sure to follow the manufacturer’s recommendations for lubrication frequency and type of lubricant to use.

Another maintenance tip for steel wire rope 5/8 is proper storage. When not in use, the rope should be stored in a dry and well-ventilated area to prevent corrosion. Avoid storing the rope in damp or humid conditions, as moisture can accelerate rusting and weaken the rope. Coiling the rope neatly and storing it on a rack or reel can help prevent kinks and tangles, which can damage the rope over time.

Regularly inspecting and maintaining the fittings and attachments used with steel wire rope 5/8 is also important. Check for signs of wear or damage on Shackles, Hooks, and Other Hardware, and replace any components that show signs of wear. Properly securing fittings and attachments to the rope can help prevent accidents and ensure the safe operation of the rope.

When using steel wire rope 5/8 for lifting or towing heavy loads, it is important to follow safe handling practices. Avoid overloading the rope beyond its rated capacity, as this can cause the rope to fail. Use proper rigging techniques and equipment, and always follow the manufacturer’s guidelines for safe use of the rope. Inspect the rope and fittings before each use to ensure they are in good condition and free from defects.

In conclusion, proper maintenance is essential for extending the lifespan of steel wire rope 5/8 and ensuring safe operation. Regular inspections, lubrication, proper storage, and safe handling practices are key components of a comprehensive maintenance program for steel wire rope 5/8. By following these maintenance tips, you can help prevent accidents, extend the lifespan of the rope, and ensure the safety of workers and equipment.

Comparison of Different Types of Steel Wire Rope 5/8 for Various Industries

Steel wire rope 5/8 is a versatile and durable material that is used in a wide range of industries for various applications. From construction to mining to marine, steel wire rope 5/8 plays a crucial role in ensuring the safety and efficiency of operations. In this article, we will compare different types of steel wire rope 5/8 and their suitability for different industries.

One of the most common types of steel wire rope 5/8 is the galvanized wire rope. Galvanized wire rope is coated with a layer of Zinc to protect it from corrosion and rust. This makes it ideal for outdoor applications where the rope is exposed to moisture and harsh weather conditions. Galvanized wire rope 5/8 is commonly used in construction, Agriculture, and marine industries.

Another type of steel wire rope 5/8 is the Stainless Steel wire rope. Stainless steel wire rope is made from high-quality stainless steel, which makes it resistant to corrosion and rust. This type of wire rope is ideal for applications where hygiene and cleanliness are important, such as in the food and pharmaceutical industries. Stainless steel wire rope 5/8 is also commonly used in marine and offshore industries where the rope is exposed to saltwater.

For heavy-duty applications, such as mining and oil and gas industries, a high-strength steel wire rope 5/8 is required. High-strength steel wire rope is made from high-tensile steel, which gives it superior strength and durability. This type of wire rope is designed to withstand heavy loads and harsh conditions, making it ideal for demanding applications.

In the transportation industry, where safety is paramount, a compacted steel wire rope 5/8 is often used. Compacted wire rope is made by compressing the strands of the rope together, which reduces the size of the rope without compromising its strength. This makes compacted wire rope ideal for applications where space is limited, such as in Elevators and cranes.

When choosing a steel wire rope 5/8 for a specific industry, it is important to consider the requirements of the application. Factors such as load capacity, environmental conditions, and safety regulations should be taken into account when selecting the right type of wire rope. Consulting with a professional engineer or supplier can help determine the best wire rope for the job.

In conclusion, steel wire rope 5/8 is a versatile and durable material that is used in a wide range of industries for various applications. Different types of steel wire rope, such as galvanized, stainless steel, high-strength, and compacted, offer unique properties that make them suitable for different industries. By understanding the requirements of the application and selecting the right type of wire rope, industries can ensure the safety and efficiency of their operations.