Table of Contents

Benefits of Using Seamless Casing Tubing Coupling in Oilfield Services

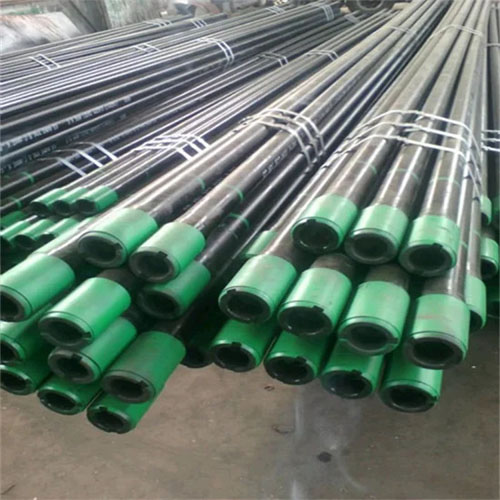

Seamless casing tubing coupling, also known as sucker rods line drill oil pipe, plays a crucial role in oilfield services. These components are essential for the extraction of oil and gas from deep within the earth. The seamless design of these couplings ensures a tight and secure connection between the various components of the drilling equipment, allowing for efficient and effective operation in challenging environments.

One of the key benefits of using seamless casing tubing coupling in oilfield services is its durability. These couplings are made from high-quality materials that can withstand the harsh conditions of drilling operations. They are designed to resist corrosion, abrasion, and other forms of wear and tear, ensuring that they can perform reliably over an extended period of time. This durability is essential for maintaining the integrity of the drilling equipment and preventing costly downtime due to equipment failure.

Another advantage of seamless casing tubing coupling is its versatility. These couplings come in a variety of sizes and configurations, allowing them to be used in a wide range of drilling applications. Whether drilling in shallow or deep wells, onshore or offshore, these couplings can be customized to meet the specific requirements of the project. This versatility makes them a valuable asset for oilfield services companies looking to maximize their operational efficiency and productivity.

In addition to durability and versatility, seamless casing tubing coupling offers superior performance in terms of pressure and temperature resistance. These couplings are designed to withstand high pressures and temperatures, making them ideal for use in challenging drilling environments. They can maintain a tight seal even under extreme conditions, ensuring that the drilling operation can proceed smoothly and safely. This performance is essential for ensuring the success of oilfield services projects and minimizing the risk of accidents or equipment failure.

Furthermore, seamless casing tubing coupling is easy to install and maintain, reducing the time and effort required to keep the drilling equipment in optimal working condition. These couplings can be quickly and securely connected to the various components of the drilling rig, allowing for fast and efficient setup and operation. Additionally, their durable design minimizes the need for frequent maintenance and replacement, saving time and money for oilfield services companies.

Overall, seamless casing tubing coupling offers a range of benefits for oilfield services companies looking to maximize their operational efficiency and productivity. From durability and versatility to superior performance and ease of installation, these couplings are an essential component of any drilling operation. By investing in high-quality seamless casing tubing coupling, oilfield services companies can ensure the success of their projects and maintain a competitive edge in the industry.

How to Properly Maintain Sucker Rods Line Drill Oil Pipe in Oilfield Operations

Oilfield operations are complex and require meticulous maintenance to ensure smooth and efficient functioning. One crucial component of oilfield services is the sucker rods line drill oil pipe, which plays a vital role in extracting oil from the ground. Proper maintenance of these components is essential to prevent costly downtime and ensure the longevity of equipment. In this article, we will discuss how to properly maintain sucker rods line drill oil pipe in oilfield operations.

Regular inspection of sucker rods line drill oil pipe is essential to identify any signs of wear and tear. Inspect the pipe for any cracks, corrosion, or other damage that could compromise its integrity. Any defects should be addressed promptly to prevent further damage and potential failure. Additionally, ensure that the pipe is properly lubricated to reduce friction and wear during operation.

https://www.youtube.com/watch?v=1OzG0ltsqcoIn addition to regular inspections, it is important to clean sucker rods line drill oil pipe regularly to remove any debris or buildup that could impede its performance. Use a suitable cleaning solution and equipment to thoroughly clean the pipe and ensure that it is free from any contaminants. Proper cleaning will help maintain the efficiency of the pipe and prevent blockages that could disrupt oil extraction.

Proper storage of sucker rods line drill oil pipe is also crucial to prevent damage and ensure its longevity. Store the pipe in a dry, well-ventilated area away from direct sunlight and extreme temperatures. Avoid stacking the pipe or placing heavy objects on top of it, as this could cause deformation or other damage. Proper storage will help preserve the integrity of the pipe and prevent premature wear and tear.

Regular maintenance of coupling and tubing is essential to ensure the seamless operation of sucker rods line drill oil pipe. Inspect the coupling and tubing for any signs of wear or damage, such as cracks or leaks, and replace them as needed. Properly maintained coupling and tubing will help prevent leaks and ensure the efficient flow of oil through the pipe.

In addition to maintaining the physical components of sucker rods line drill oil pipe, it is important to monitor the pressure and flow rate of the oil during operation. Regularly check the pressure Gauges and flow meters to ensure that they are within the recommended range. Any deviations from the normal operating parameters should be investigated and addressed promptly to prevent equipment failure.

Proper maintenance of sucker rods line drill oil pipe is essential to ensure the smooth and efficient operation of oilfield services. By regularly inspecting, cleaning, and storing the pipe, as well as maintaining coupling and tubing, operators can prevent costly downtime and ensure the longevity of equipment. Monitoring pressure and flow rates during operation will help identify any issues early and prevent potential failures. With proper maintenance, sucker rods line drill oil pipe can continue to extract oil efficiently and effectively in oilfield operations.