Table of Contents

The Process of Manufacturing SAE1010 Brake Pads Steel Back Plates

Brake pads are an essential component of any vehicle’s braking system, providing the necessary friction to slow Down or stop a moving vehicle. One crucial part of a brake Pad is the steel back plate, which provides structural support and stability to the pad. In this article, we will explore the process of manufacturing SAE1010 brake pads steel back plates in a factory setting.

The first step in producing SAE1010 brake pads steel back plates is to procure the raw materials. SAE1010 steel is a low-Carbon Steel that is commonly used in the automotive industry due to its excellent formability and weldability. The steel is typically sourced in the form of coils or sheets and undergoes a thorough inspection to ensure quality and consistency.

Once the raw materials are approved, the steel is cut into the desired shape and size using precision cutting machines. This step is crucial in ensuring that the steel back plates meet the exact specifications required for the brake pads. The cut pieces are then cleaned and deburred to remove any sharp edges or burrs that could affect the performance of the brake pads.

After the steel back plates are cut and cleaned, they undergo a series of forming processes to give them the necessary shape and curvature. This is typically done using Hydraulic Presses or stamping machines that apply pressure to the steel, shaping it into the desired form. The formed back plates are then heat-treated to improve their strength and durability, ensuring that they can withstand the high temperatures and pressures generated during braking.

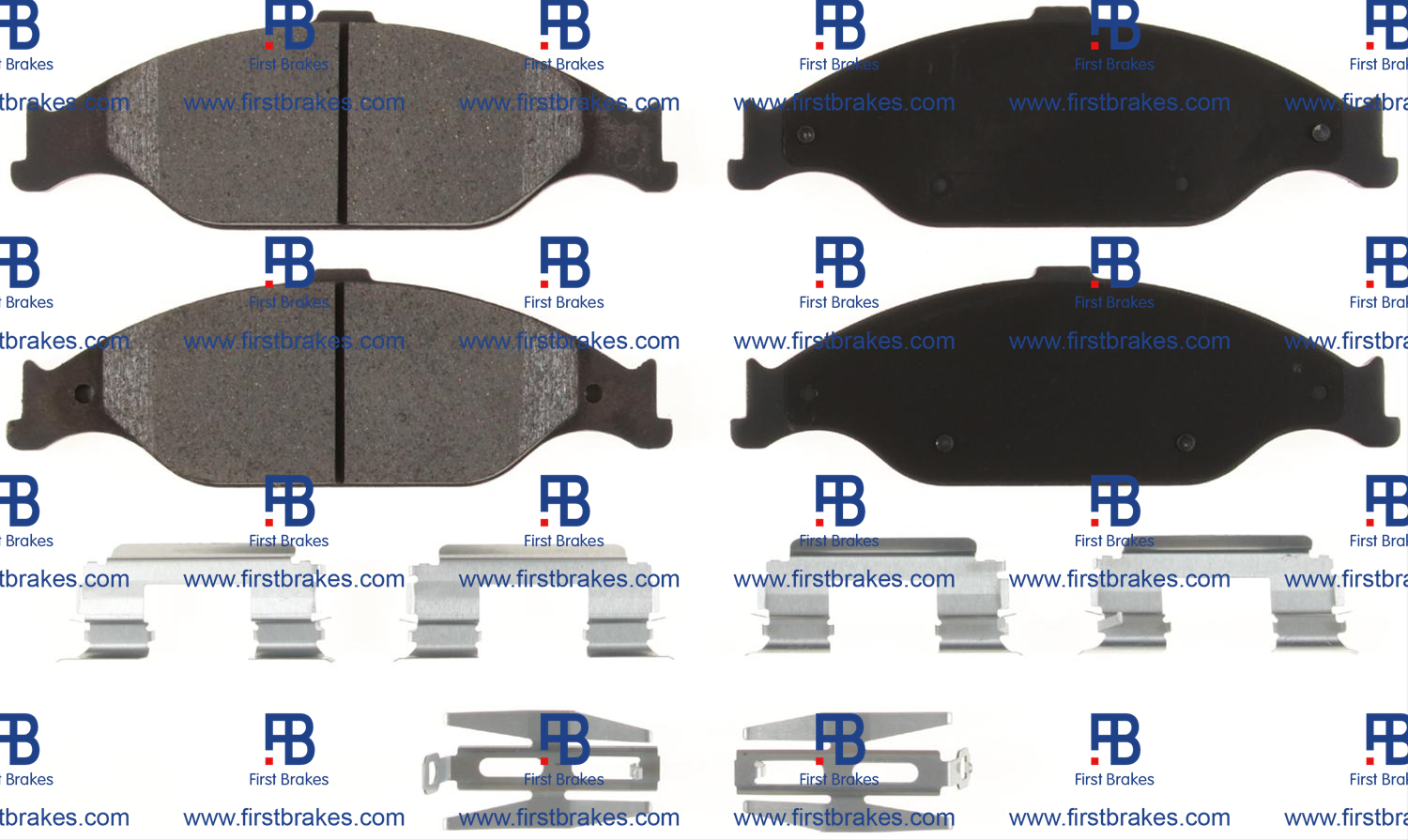

Once the steel back plates have been formed and heat-treated, they are coated with a protective layer to prevent corrosion and improve their appearance. This coating can be applied using various methods, such as painting, powder coating, or plating, depending on the specific requirements of the brake pad manufacturer. The coated back plates are then cured in ovens to ensure that the coating adheres properly and provides long-lasting protection.

After the coating process is complete, the steel back plates undergo a final inspection to check for any defects or imperfections. This inspection is crucial in ensuring that the back plates meet the strict quality standards required for automotive applications. Any faulty back plates are rejected, while those that pass inspection are packaged and prepared for shipment to the brake pad manufacturer.

In conclusion, the process of manufacturing SAE1010 brake pads steel back plates is a complex and precise operation that requires careful attention to detail and quality control. From procuring raw materials to forming, heat-treating, coating, and inspecting the back plates, each step plays a crucial role in ensuring the performance and reliability of the final product. By following strict manufacturing processes and quality standards, factories can produce high-quality steel back plates that meet the demanding requirements of the automotive industry.