Table of Contents

Best Chinese Exporters for Asphalt Production Temperature Aids

Asphalt production temperature plays a crucial role in the manufacturing of warm mix asphalt modifiers. Warm mix asphalt is a sustainable alternative to traditional hot mix asphalt, as it requires lower production temperatures, which in turn reduces energy consumption and greenhouse gas emissions. In recent years, the demand for warm mix asphalt modifiers has been on the rise, as governments and industries worldwide are increasingly focusing on sustainable practices.

One of the key components in warm mix asphalt modifiers is the use of additives that lower the production temperature of the asphalt mix. These additives are typically organic or chemical compounds that help reduce the viscosity of the asphalt binder at lower temperatures, allowing for easier mixing and compaction. By using these additives, asphalt producers can achieve the same level of performance and durability as traditional hot mix asphalt, while also reaping the environmental benefits of reduced energy consumption and emissions.

| No. | Product Name |

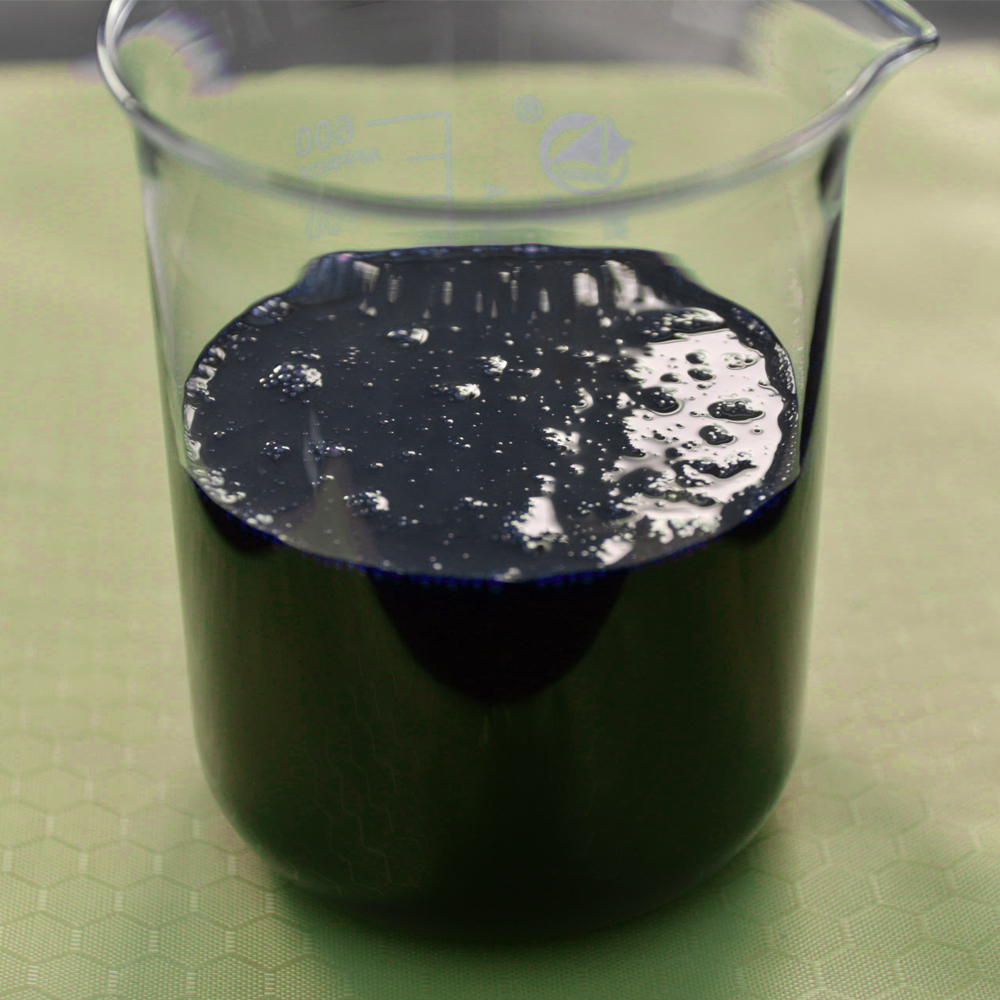

| 1 | Warm Mix Bituminous Modifier |

Chinese exporters have been at the forefront of supplying high-quality warm mix asphalt modifiers to the global market. With their advanced manufacturing capabilities and competitive pricing, Chinese exporters have become a preferred choice for many asphalt producers looking to incorporate warm mix asphalt technology into their operations. In addition, Chinese exporters have also been investing in research and development to improve the performance and efficiency of their warm mix asphalt modifiers, making them a reliable partner for asphalt producers worldwide.

The success of Chinese exporters in the warm mix asphalt modifiers market can be attributed to their expertise in asphalt production temperature aids. By understanding the complex interactions between different additives and the asphalt binder, Chinese exporters have been able to develop innovative solutions that meet the specific needs of their customers. Whether it’s improving workability, reducing emissions, or enhancing durability, Chinese exporters have the knowledge and resources to deliver customized warm mix asphalt modifiers that perform optimally in various conditions.

Furthermore, Chinese exporters have also been proactive in collaborating with industry stakeholders to promote the adoption of warm mix asphalt technology. By participating in industry conferences, workshops, and trade shows, Chinese exporters have been able to showcase their products and share their expertise with a wider audience. This collaborative approach has not only helped raise awareness about the benefits of warm mix asphalt modifiers but has also fostered partnerships with asphalt producers and contractors around the world.

In conclusion, asphalt production temperature aids are essential for the successful manufacturing of warm mix asphalt modifiers. Chinese exporters have emerged as leaders in this field, offering high-quality products that meet the stringent requirements of the global market. With their expertise in asphalt production temperature aids and commitment to sustainability, Chinese exporters are well-positioned to drive the growth of warm mix asphalt technology and contribute to a more sustainable future for the asphalt industry.

Warm Mix Asphalt Component: Asphalt Production Temperature Aids

Asphalt production temperature plays a crucial role in the production of warm mix asphalt modifiers. Warm mix asphalt is a sustainable alternative to traditional hot mix asphalt, as it requires lower production temperatures, which in turn reduces energy consumption and greenhouse gas emissions. The use of warm mix asphalt modifiers further enhances the performance of the asphalt mixture, making it more durable and resistant to cracking and rutting.

One of the key components in warm mix asphalt modifiers is the use of additives that lower the production temperature of the asphalt mixture. These additives can be organic or chemical in nature, and they work by reducing the viscosity of the asphalt binder, allowing it to be mixed at lower temperatures. This not only saves energy during production but also reduces the risk of aging and oxidation of the asphalt binder, resulting in a longer-lasting pavement.

The production temperature of warm mix asphalt modifiers typically Ranges from 30 to 100 degrees Fahrenheit lower than that of traditional hot mix asphalt. This lower temperature not only reduces energy consumption but also minimizes the release of harmful emissions into the atmosphere. In addition, the use of warm mix asphalt modifiers can improve the workability of the asphalt mixture, making it easier to compact and achieve a smooth surface finish.

One of the key benefits of using warm mix asphalt modifiers is the ability to produce asphalt mixtures that are more resistant to moisture damage. By lowering the production temperature, the additives in warm mix asphalt modifiers help to maintain the properties of the asphalt binder, preventing it from becoming brittle and susceptible to cracking. This results in a more durable pavement that can withstand the effects of freeze-thaw cycles and heavy traffic loads.

Another advantage of using warm mix asphalt modifiers is the ability to extend the paving season in colder climates. Traditional hot mix asphalt production is often limited to the warmer months of the year, when temperatures are high enough to allow for proper compaction of the asphalt mixture. By using warm mix asphalt modifiers, contractors can produce asphalt mixtures at lower temperatures, allowing them to pave roads and highways in colder weather conditions.

In conclusion, asphalt production temperature plays a critical role in the production of warm mix asphalt modifiers. By lowering the production temperature of the asphalt mixture, additives in warm mix asphalt modifiers help to reduce energy consumption, minimize emissions, and improve the performance of the pavement. With the use of warm mix asphalt modifiers, contractors can produce durable, long-lasting asphalt mixtures that are resistant to moisture damage and can be paved in a wider range of weather conditions. By incorporating warm mix asphalt modifiers into their production processes, Chinese exporters can enhance the quality and sustainability of their asphalt products, making them more competitive in the global market.