Table of Contents

The Importance of Monitoring TDS Levels in RO Water Systems

Total Dissolved Solids (TDS) refer to the amount of Inorganic Salts, Minerals, and metals dissolved in water. In the context of Reverse Osmosis (RO) water systems, monitoring TDS levels is crucial to ensure the effectiveness and efficiency of the system. A TDS meter is a device used to measure the concentration of TDS in water, providing valuable information about water quality.

RO water systems are designed to remove impurities from water by forcing it through a semi-permeable membrane. This process effectively removes contaminants such as bacteria, viruses, and Chemicals, producing clean and safe Drinking Water. However, over time, the membrane can become clogged with impurities, reducing its efficiency and potentially allowing harmful substances to pass through.

By regularly monitoring TDS levels in RO water systems, users can determine when the membrane needs to be cleaned or replaced. A TDS meter provides a quick and easy way to check the quality of the water produced by the system, helping to maintain optimal performance and ensure the Safety of the water.

High TDS levels in RO water can indicate a variety of issues, such as a worn-out membrane, inadequate pre-filtration, or contamination of the source water. If left unchecked, these problems can Lead to poor water quality, reduced system efficiency, and potential health risks. By using a TDS meter to monitor TDS levels, users can identify and address these issues before they escalate.

In addition to maintaining the performance of the RO water system, monitoring TDS levels can also help users track changes in water quality over time. By regularly testing the water produced by the system, users can identify trends and patterns in TDS levels, allowing them to make informed decisions about water treatment and filtration.

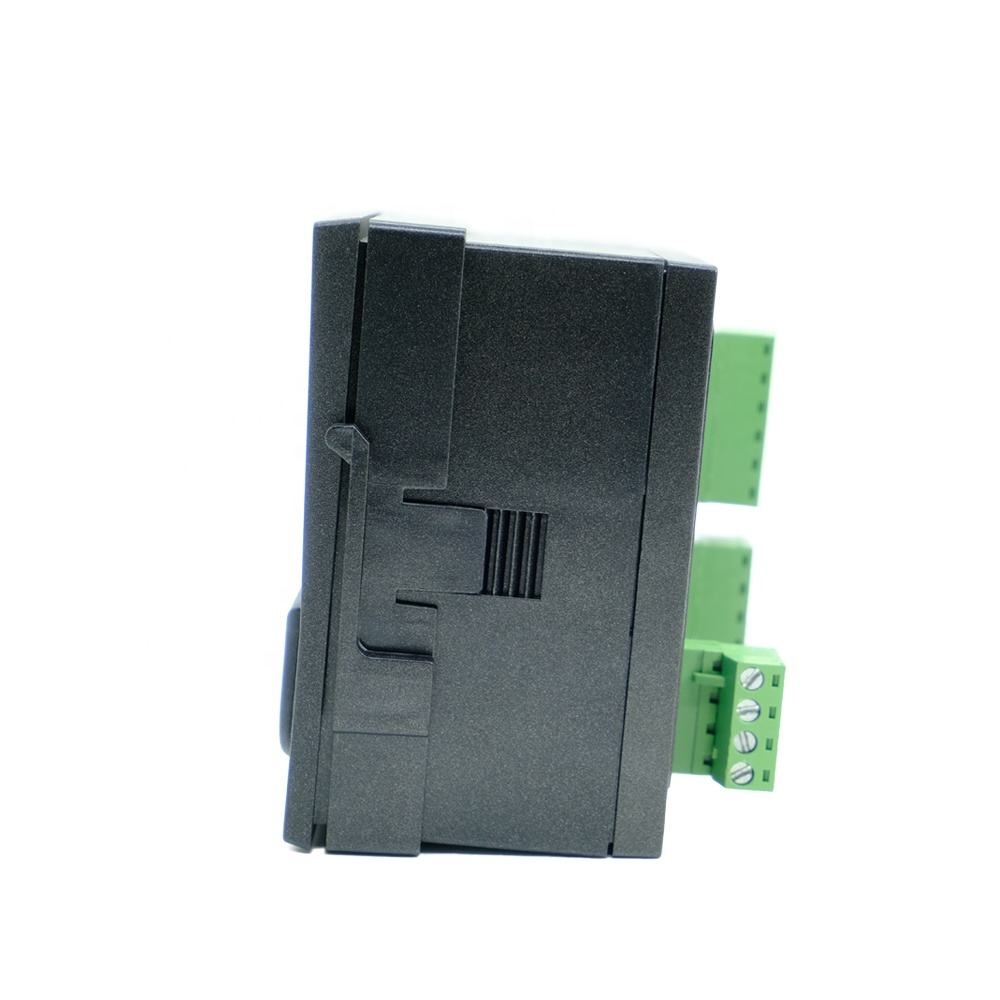

| ROS-360 Water Treatment RO Programmer Controller | ||

| Model | ROS-360 Single Stage | ROS-360 Double Stage |

| Measuring range | Source water0~2000uS/cm | Source water0~2000uS/cm |

| \\u3000 | First level effluent 0~1000uS/cm | First level effluent 0~1000uS/cm |

| \\u3000 | secondary effluent 0~100uS/cm | secondary effluent 0~100uS/cm |

| Pressure sensor(optional) | Membrane pre/post pressure | Primary/ secondary membrane front/rear pressure |

| Flow Sensor(optional) | 2 channels (Inlet/outlet flow rate) | 3 channels (source water, primary flow,secondary flow) |

| IO input | 1.Raw water low pressure | 1.Raw water low pressure |

| \\u3000 | 2.Primary booster pump inlet low pressure | 2.Primary booster pump inlet low pressure |

| \\u3000 | 3.Primary booster pump outlet high pressure | 3.Primary booster pump outlet high pressure |

| \\u3000 | 4.High liquid level of Level 1 tank | 4.High liquid level of Level 1 tank |

| \\u3000 | 5.Low liquid level of Level 1 tank | 5.Low liquid level of Level 1 tank |

| \\u3000 | 6.Preprocessing signal\\u00a0 | 6.2nd booster pump outlet high pressure |

| \\u3000 | \\u3000 | 7.High liquid level of Level 2 tank |

| \\u3000 | \\u3000 | 8.Preprocessing signal |

| Relay output (passive) | 1.Water inlet valve | 1.Water inlet valve |

| \\u3000 | 2.Source water pump | 2.Source water pump |

| \\u3000 | 3.Booster pump | 3.Primary booster pump |

| \\u3000 | 4.Flush valve | 4.Primary flush valve |

| \\u3000 | 5.Water over standard discharge valve | 5.Primary water over standard discharge valve |

| \\u3000 | 6.Alarm output node | 6.Secondary booster pump |

| \\u3000 | 7.Manual standby pump | 7.Secondary flush valve |

| \\u3000 | \\u3000 | 8.Secondary water over standard discharge valve |

| \\u3000 | \\u3000 | 9.Alarm output node |

| \\u3000 | \\u3000 | 10.Manual standby pump |

| The main function | 1.Correction of electrode constant | 1.Correction of electrode constant |

| \\u3000 | 2.TDS alarm setting | 2.TDS alarm setting |

| \\u3000 | 3.All working mode time can be set | 3.All working mode time can be set |

| \\u3000 | 4.High and low pressure flushing mode setting | 4.High and low pressure flushing mode setting |

| \\u3000 | 5.Manual/automatic can be chosen when boot up | 5.Manual/automatic can be chosen when boot up |

| \\u3000 | 6.Manual debugging mode | 6.Manual debugging mode |

| \\u3000 | 7.Spare parts time management | 7.Spare parts time management |

| Expansion interface | 1.Reserved relay output | 1.Reserved relay output |

| \\u3000 | 2.RS485 communication | 2.RS485 communication |

| Power supply | DC24V\\u00b110% | DC24V\\u00b110% |

| Relative humidity | \\u226685% | \\u226485% |

| Environment temperature | 0~50\\u2103 | 0~50\\u2103 |

| Touch screen size | Touch screen size: 7 inches 203*149*48mm (Hx Wx D) | Touch screen size: 7 inches 203*149*48mm (Hx Wx D) |

| Hole Size | 190x136mm(HxW) | 190x136mm(HxW) |

| Installation | Embedded | Embedded |

For example, a sudden increase in TDS levels could indicate a problem with the system or source water, prompting users to take corrective action. Conversely, a gradual decrease in TDS levels may suggest that the membrane is becoming less effective and needs to be replaced. By monitoring TDS levels consistently, users can stay ahead of potential issues and ensure the continued reliability of their RO water system.

In conclusion, monitoring TDS levels in RO water systems is essential for maintaining water quality, system performance, and user safety. A TDS meter provides a simple and effective way to measure TDS levels, allowing users to identify problems, track changes, and make informed decisions about water treatment. By incorporating regular TDS testing into their maintenance routine, users can ensure that their RO water system continues to provide clean, safe, and reliable drinking water for years to come.

How to Use a TDS Meter to Ensure Optimal Performance of Your RO Water Filter

RO water TDS meter is a crucial tool for ensuring the optimal performance of your reverse osmosis water filter. Total Dissolved Solids (TDS) refer to the amount of inorganic salts, minerals, and metals present in water. These impurities can affect the taste, odor, and overall quality of your drinking water. By using a TDS meter, you can monitor the effectiveness of your RO water filter and make necessary adjustments to maintain clean and healthy drinking water.

To use a TDS meter, start by turning it on and allowing it to calibrate. Once the meter is ready, simply dip the probe into a sample of water from your RO system. Make sure the probe is fully submerged and wait for the reading to stabilize. The TDS meter will display the total dissolved solids in parts per million (ppm). A lower TDS reading indicates cleaner water, while a higher reading suggests the presence of impurities.

Regularly testing the TDS of your RO water is essential for ensuring that your filter is functioning properly. If you notice a significant increase in TDS levels, it may be time to replace the filter cartridges or perform maintenance on your system. By monitoring the TDS of your water, you can prevent the buildup of contaminants and ensure that your RO system is providing you with clean and safe drinking water.

In addition to monitoring TDS levels, it is also important to calibrate your TDS meter regularly to ensure accurate readings. Calibration involves adjusting the meter to account for any changes in its accuracy over time. Most TDS meters come with calibration solutions that allow you to adjust the readings to match a known standard. By calibrating your TDS meter regularly, you can trust that the readings are accurate and reliable.

When using a TDS meter, it is important to take multiple readings from different sources to get a comprehensive understanding of your water quality. Test the water from your RO system, as well as from other sources such as tap water or bottled water. Comparing the TDS levels of different water sources can help you identify any discrepancies and make informed decisions about the quality of your drinking water.

In conclusion, using a TDS meter is an essential tool for ensuring the optimal performance of your RO water filter. By regularly monitoring the TDS levels of your water, you can maintain clean and healthy drinking water for you and your family. Remember to calibrate your TDS meter regularly and take multiple readings from different sources to get a comprehensive understanding of your water quality. With proper maintenance and monitoring, you can enjoy the benefits of clean and safe drinking water from your RO system.