Table of Contents

Advantages of Using Q195/Q235/Q345/Ss400/A36/Q235B/Q275sch40 Carbon Steel Pipe for Welded/Seamless Applications

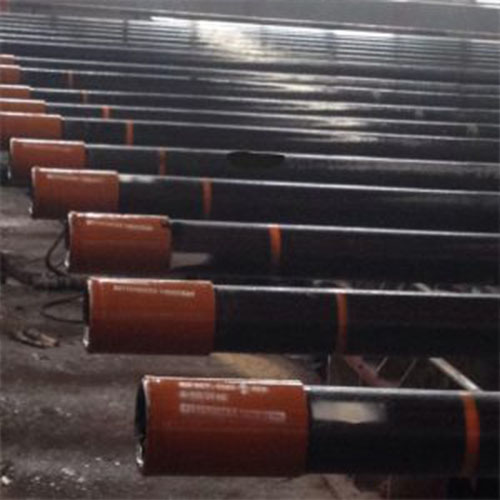

Carbon Steel Pipes are widely used in various industries for a multitude of applications due to their durability, strength, and versatility. Among the different grades of carbon steel available in the market, Q195, Q235, Q345, Ss400, A36, Q235B, and Q275sch40 are some of the most commonly used grades for welded and seamless carbon steel pipes. These grades offer a range of advantages that make them ideal for a wide range of applications.

One of the key advantages of using Q195/Q235/Q345/Ss400/A36/Q235B/Q275sch40 carbon steel pipes is their high strength-to-weight ratio. These grades of carbon steel are known for their excellent tensile strength, which makes them suitable for applications where high strength and durability are required. Whether used in structural applications, machinery, or construction projects, these carbon steel pipes can withstand heavy loads and harsh environmental conditions without compromising on performance.

In addition to their high strength, Q195/Q235/Q345/Ss400/A36/Q235B/Q275sch40 carbon steel pipes also offer excellent weldability. Welding is a common method used to join carbon steel pipes in various applications, and the weldability of these grades ensures that strong and reliable joints can be achieved with ease. This makes them ideal for use in welded structures, pipelines, and other applications where welding is required.

Furthermore, Q195/Q235/Q345/Ss400/A36/Q235B/Q275sch40 carbon steel pipes are known for their corrosion resistance. These grades of carbon steel are often coated with a layer of Zinc to provide additional protection against corrosion, making them suitable for use in outdoor and corrosive environments. The high zinc coating on these pipes helps to prevent rust and corrosion, extending the lifespan of the pipes and reducing maintenance costs over time.

Another advantage of using Q195/Q235/Q345/Ss400/A36/Q235B/Q275sch40 carbon steel pipes is their cost-effectiveness. Compared to other materials such as Stainless Steel or Aluminum, carbon steel pipes are more affordable, making them a cost-effective choice for a wide range of applications. Whether used in construction, manufacturing, or infrastructure projects, these carbon steel pipes offer a cost-effective solution without compromising on quality or performance.

Moreover, Q195/Q235/Q345/Ss400/A36/Q235B/Q275sch40 carbon steel pipes are readily available in a variety of shapes and sizes, including round, square, and rectangular. This versatility makes them suitable for a wide range of applications, from structural support to fluid transportation. Whether you need a pipe for a specific application or a custom solution, these carbon steel pipes can be easily sourced and tailored to meet your requirements.

In conclusion, Q195/Q235/Q345/Ss400/A36/Q235B/Q275sch40 carbon steel pipes offer a range of advantages that make them ideal for welded and seamless applications. From their high strength and weldability to their corrosion resistance and cost-effectiveness, these grades of carbon steel provide a reliable and versatile solution for a wide range of industries. Whether used in construction, manufacturing, or infrastructure projects, these carbon steel pipes are a dependable choice that can withstand the demands of various applications.

Comparison of High Zinc Coating Gi/Gl Carbon Steel Pipe vs. Other Coating Options

When it comes to choosing the right type of carbon steel pipe for your project, there are a variety of options available on the market. One popular choice is the high zinc coating Gi/Gl carbon steel pipe, which offers a number of advantages over other coating options. In this article, we will compare the high zinc coating Gi/Gl carbon steel pipe with other coating options to help you make an informed decision for your next project.

One of the key benefits of the high zinc coating Gi/Gl carbon steel pipe is its superior corrosion resistance. The high zinc coating provides a protective barrier that helps prevent rust and corrosion, making it ideal for use in outdoor or high-moisture environments. This can help extend the lifespan of the pipe and reduce the need for frequent maintenance or replacement.

In addition to its corrosion resistance, the high zinc coating Gi/Gl carbon steel pipe also offers excellent durability and strength. The zinc coating helps protect the underlying steel from damage, such as scratches or dents, which can help maintain the structural integrity of the pipe over time. This can be especially important in applications where the pipe is exposed to heavy loads or harsh conditions.

Another advantage of the high zinc coating Gi/Gl carbon steel pipe is its versatility. This type of pipe can be used in a wide range of applications, including plumbing, construction, and manufacturing. Its high zinc coating makes it suitable for both indoor and outdoor use, and it can be easily welded or sealed for a secure fit. This versatility can help streamline the construction process and reduce the need for multiple types of pipe for different applications.

In comparison to other coating options, such as epoxy or paint, the high zinc coating Gi/Gl carbon steel pipe offers a more cost-effective solution. The zinc coating is applied using a hot-dip process, which is both efficient and economical. This can help lower the overall cost of the project without sacrificing quality or performance.

While the high zinc coating Gi/Gl carbon steel pipe offers many advantages, it is important to consider the specific requirements of your project before making a decision. Other coating options, such as epoxy or paint, may be better suited for certain applications where additional properties, such as chemical resistance or color options, are needed. It is important to consult with a professional to determine the best coating option for your specific needs.

In conclusion, the high zinc coating Gi/Gl carbon steel pipe offers a number of advantages over other coating options, including superior corrosion resistance, durability, strength, versatility, and cost-effectiveness. By carefully considering the requirements of your project and consulting with a professional, you can make an informed decision on the best type of carbon steel pipe for your next project.