Table of Contents

Benefits of Using Precision Stainless Steel Pipe Tube in Oil/Gas Drilling Boilers

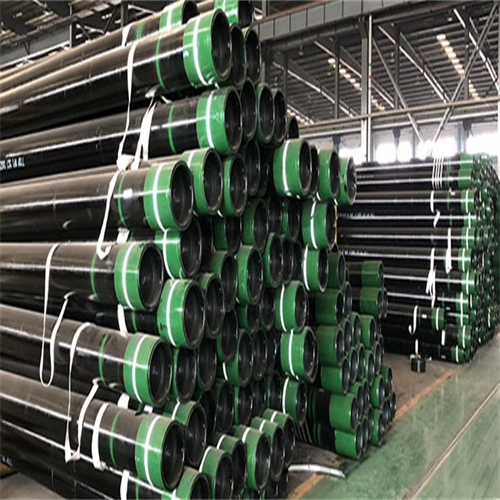

Oil and gas drilling operations require precision and reliability to ensure the Safety and efficiency of the process. One crucial component in these operations is the boiler, which plays a vital role in generating the steam needed for various drilling activities. To ensure the optimal performance of these boilers, it is essential to use high-quality materials that can withstand the harsh conditions of the drilling Environment. Precision stainless steel pipe tubes, manufactured according to ASTM/DIN standards, are an excellent choice for this purpose.

Precision stainless steel pipe tubes offer a range of benefits that make them ideal for use in oil and gas drilling boilers. One of the key advantages of using stainless steel is its corrosion resistance. The harsh conditions of oil and gas drilling operations, including exposure to high temperatures, pressure, and corrosive substances, can cause significant damage to traditional materials. Stainless steel, however, is highly resistant to corrosion, making it a durable and long-lasting option for boiler components.

In addition to its corrosion resistance, stainless steel also offers excellent strength and durability. This is crucial in oil and gas drilling operations, where equipment is subjected to high Levels of stress and pressure. Precision stainless steel pipe tubes, manufactured to ASTM/DIN standards, are designed to withstand these extreme conditions, ensuring the reliability and safety of the boiler.

Another benefit of using precision stainless steel pipe tubes in oil and gas drilling boilers is their high temperature resistance. Stainless steel can withstand high temperatures without losing its structural integrity, making it an ideal material for boiler components that are exposed to heat during the drilling process. This high temperature resistance helps to prevent the degradation of the boiler over time, ensuring its continued performance and efficiency.

Furthermore, stainless steel is easy to clean and maintain, making it a cost-effective option for oil and gas drilling operations. Regular maintenance is essential to ensure the optimal performance of boilers in these environments, and stainless steel simplifies this process by requiring minimal upkeep. This can help to reduce downtime and maintenance costs, ultimately improving the overall efficiency of the drilling operation.

Precision stainless steel pipe tubes also offer excellent dimensional accuracy, ensuring a perfect fit for boiler components. This precision manufacturing process, in accordance with ASTM/DIN standards, helps to minimize the risk of leaks or other issues that can compromise the performance of the boiler. By using stainless steel pipe tubes with precise dimensions, operators can have confidence in the reliability and safety of their drilling equipment.

In conclusion, the benefits of using precision stainless steel pipe tubes in oil and gas drilling boilers are clear. From their corrosion resistance and high temperature resistance to their strength, durability, and ease of maintenance, stainless steel offers a range of advantages that make it an ideal choice for boiler components. By investing in high-quality stainless steel pipe tubes manufactured to ASTM/DIN standards, operators can ensure the safety, reliability, and efficiency of their drilling operations.