Table of Contents

Advantages of Using Nylon Drill Pipe Casing

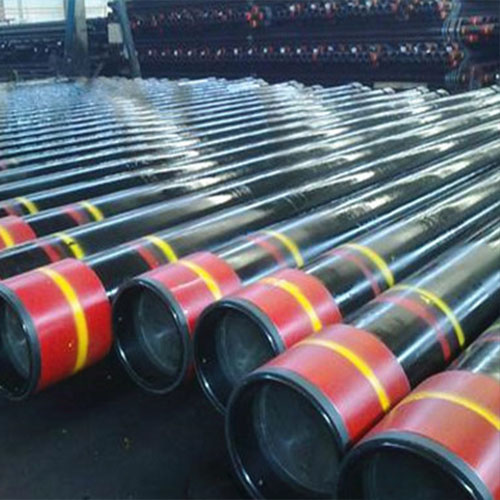

Nylon drill pipe casing drift tubing drift gauge API 5CT is a type of casing used in the oil and gas industry. It is made from nylon, a durable and lightweight material that offers several advantages over traditional steel casing. In this article, we will discuss the benefits of using nylon drill pipe casing and why it is becoming increasingly popular in the industry.

One of the main advantages of nylon drill pipe casing is its lightweight nature. Nylon is significantly lighter than steel, making it easier to transport and handle on the rig. This can help reduce the risk of injuries to workers and improve overall efficiency on the job site. Additionally, the lightweight nature of nylon casing can also reduce the overall weight of the drilling operation, which can Lead to cost savings in terms of fuel consumption and equipment wear and tear.

Another advantage of nylon drill pipe casing is its resistance to corrosion. Steel casing is prone to rust and corrosion over time, especially in harsh environments such as offshore drilling rigs. Nylon, on the other hand, is highly resistant to corrosion, making it a more durable and long-lasting option for casing. This can help extend the life of the casing and reduce the need for frequent replacements, saving time and money in the long run.

In addition to its corrosion resistance, nylon drill pipe casing is also highly resistant to Chemicals and other harsh substances commonly found in drilling operations. This can help prevent damage to the casing and ensure that it remains intact and functional throughout the drilling process. The durability of nylon casing can also help reduce the risk of leaks and other issues that can arise from damaged or compromised casing.

Furthermore, nylon drill pipe casing is easy to install and maintain. Unlike steel casing, which can be heavy and difficult to handle, nylon casing is lightweight and easy to maneuver. This can help speed up the installation process and reduce downtime on the rig. Additionally, nylon casing requires minimal maintenance compared to steel casing, as it does not require painting or coating to protect against corrosion. This can help save time and money on maintenance costs over the life of the casing.

Overall, nylon drill pipe casing offers several advantages over traditional steel casing, including its lightweight nature, corrosion resistance, chemical resistance, and ease of installation and maintenance. These benefits make nylon casing an attractive option for drilling operations looking to improve efficiency, reduce costs, and increase overall Safety on the job site. As the oil and gas industry continues to evolve, nylon drill pipe casing is likely to become an increasingly popular choice for casing applications.

Importance of Tubing Drift Gauge in API 5CT Standards

Nylon Drill Pipe Casing Drift Tubing Drift Gauge API 5CT

In the oil and gas industry, ensuring the integrity of drilling equipment is of utmost importance. One crucial tool used for this purpose is the tubing drift gauge, which plays a vital role in maintaining the quality and safety of drilling operations. The American Petroleum Institute (API) has set standards for tubing drift Gauges to ensure that they meet the necessary requirements for use in the industry.

Tubing drift gauges are used to measure the internal diameter of tubing, casing, and drill pipe to ensure that they are within the specified tolerances. This is important because any deviation from the required dimensions can lead to issues such as stuck pipe, poor cementing, and even wellbore collapse. By using a tubing drift gauge, operators can quickly identify any anomalies in the equipment and take corrective action before they escalate into more significant problems.

The API 5CT standard sets guidelines for the design, manufacturing, and testing of tubing drift gauges to ensure their reliability and accuracy. These standards cover various aspects such as material selection, dimensional tolerances, and performance requirements. By adhering to these standards, manufacturers can produce tubing drift gauges that meet the industry’s stringent requirements and provide operators with the confidence that their equipment is in good working condition.

One of the key benefits of using a tubing drift gauge that meets API 5CT standards is the assurance of quality and consistency. These gauges are designed to withstand the harsh conditions encountered in drilling operations, such as high temperatures, pressure, and corrosive fluids. By using a high-quality tubing drift gauge, operators can minimize the risk of equipment failure and ensure the safety of personnel and the Environment.

https://www.youtube.com/watch?v=J1ao9j7SS_YFurthermore, tubing drift gauges that comply with API 5CT standards are more likely to provide accurate and reliable measurements. This is essential for ensuring that the equipment being used meets the required specifications and can perform its intended function effectively. By using a properly calibrated tubing drift gauge, operators can avoid costly mistakes and delays in drilling operations.

Another important aspect of tubing drift gauges in API 5CT standards is their role in quality control and assurance. By using gauges that have been tested and certified to meet the API standards, operators can be confident that they are using equipment that has been thoroughly inspected and verified for accuracy. This can help prevent issues such as equipment failure, non-compliance with regulations, and costly downtime.

In conclusion, tubing drift gauges play a critical role in maintaining the integrity and safety of drilling operations in the oil and gas industry. By adhering to API 5CT standards for tubing drift gauges, operators can ensure that they are using high-quality equipment that meets the industry’s stringent requirements. This not only helps to prevent costly mistakes and delays but also ensures the safety of personnel and the environment. By investing in quality tubing drift gauges that comply with API standards, operators can improve the efficiency and reliability of their drilling operations.

How to Properly Measure and Inspect Drill Pipe Casing Drift Tubing

When it comes to drilling operations, ensuring the integrity and quality of the equipment being used is crucial for the success and safety of the project. One important aspect of this is properly measuring and inspecting drill pipe casing drift tubing. This process is essential for determining the suitability of the tubing for use in drilling operations and ensuring that it meets the necessary standards and specifications.

One commonly used tool for measuring and inspecting drill pipe casing drift tubing is the API 5CT tubing drift gauge. This gauge is designed to accurately measure the internal diameter of the tubing and ensure that it meets the requirements set forth by the American Petroleum Institute (API). By using this tool, drillers can quickly and easily determine whether the tubing is within the acceptable tolerance range and is suitable for use in drilling operations.

To properly measure and inspect drill pipe casing drift tubing using the API 5CT tubing drift gauge, there are a few key steps that need to be followed. The first step is to ensure that the tubing is clean and free of any debris or obstructions that could affect the accuracy of the measurements. Once the tubing is clean, the next step is to insert the drift gauge into the tubing and push it through to the other end. As the gauge is pushed through the tubing, it will measure the internal diameter and provide a reading that indicates whether the tubing is within the acceptable tolerance range.

It is important to note that the API 5CT tubing drift gauge is designed to measure the internal diameter of the tubing, not the external diameter. This is because the internal diameter is the critical measurement when it comes to determining whether the tubing is suitable for use in drilling operations. By accurately measuring the internal diameter, drillers can ensure that the tubing will fit properly with other equipment and will not cause any issues during the drilling process.

In addition to measuring the internal diameter of the tubing, it is also important to visually inspect the tubing for any signs of damage or wear. This can include looking for dents, cracks, or other defects that could affect the integrity of the tubing. If any damage is found, it is important to address it immediately and determine whether the tubing is still suitable for use in drilling operations.

Overall, properly measuring and inspecting drill pipe casing drift tubing is essential for ensuring the quality and integrity of the equipment being used in drilling operations. By using tools like the API 5CT tubing drift gauge, drillers can quickly and accurately determine whether the tubing meets the necessary standards and specifications. This not only helps to ensure the success and safety of the drilling project but also helps to prolong the life of the equipment and reduce the risk of costly downtime due to equipment failure.