Inhoudsopgave

Benefits of Compatibility Testing for Asphalt Adhesion Promoters

Asphalt adhesion promoters are essential additives used in the construction industry to improve the bond between asphalt and various surfaces. These promoters play a crucial role in enhancing the durability and performance of asphalt pavements. However, the effectiveness of these adhesion promoters largely depends on their compatibility with the asphalt mixture. Compatibility testing is a critical step in ensuring that the adhesion promoter will work effectively with the asphalt.

One of the key benefits of compatibility testing is that it helps to determine the optimal dosage of the adhesion promoter. By testing the compatibility of the promoter with the asphalt mixture, engineers can identify the ideal concentration that will provide the best adhesion properties. This ensures that the adhesion promoter is not overused, which can Lead to issues such as reduced flexibility or cracking in the pavement.

Additionally, compatibility testing helps to assess the long-term performance of the adhesion promoter. By subjecting the asphalt mixture to various environmental conditions, such as temperature fluctuations and moisture exposure, engineers can evaluate how well the adhesion promoter maintains its bond with the asphalt over time. This information is crucial for ensuring the longevity of the pavement and preventing premature deterioration.

| No. | Commodity Name |

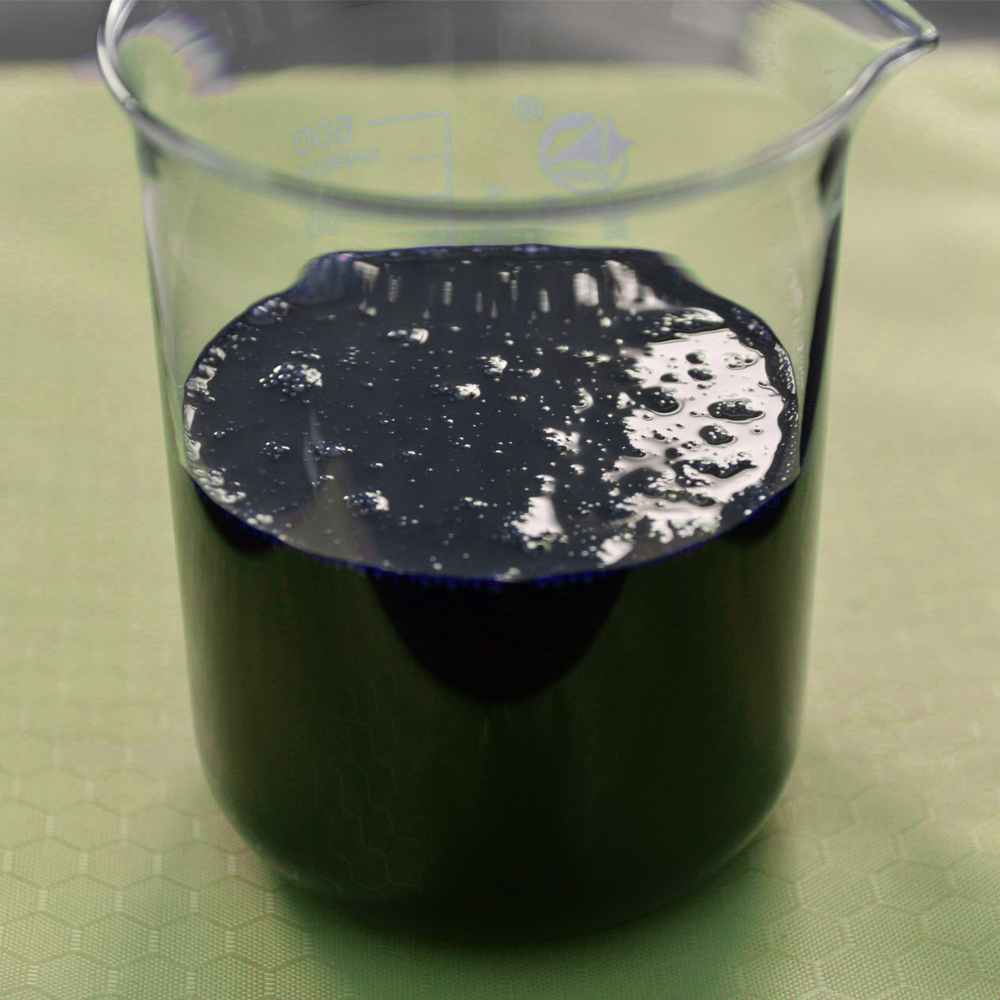

| 1 | Liquid Anti-strip Agents |

Furthermore, compatibility testing can help to identify any potential compatibility issues between the adhesion promoter and other additives in the asphalt mixture. Incompatibility between additives can lead to issues such as poor adhesion, reduced strength, or even pavement failure. By conducting thorough compatibility testing, engineers can avoid these problems and ensure that all additives work together harmoniously to enhance the performance of the pavement.

Another benefit of compatibility testing is that it allows engineers to tailor the adhesion promoter to specific project requirements. Different projects may have varying performance demands, such as high traffic volumes, extreme weather conditions, or specific surface types. By testing the compatibility of the adhesion promoter with the asphalt mixture, engineers can customize the formulation to meet the unique needs of each project, ensuring optimal performance and longevity.

In conclusion, compatibility testing is a crucial step in the development and implementation of asphalt adhesion promoters. By assessing the compatibility of the promoter with the asphalt mixture, engineers can determine the optimal dosage, evaluate long-term performance, identify potential compatibility issues, and tailor the formulation to specific project requirements. These benefits ultimately lead to improved adhesion, durability, and performance of asphalt pavements, making compatibility testing an essential tool for ensuring the success of construction projects.

Importance of Asphalt Compatibility Testing in Construction Projects

Asphalt adhesion promoters play a crucial role in enhancing the bond between asphalt and various surfaces in construction projects. These promoters are designed to improve the adhesion of asphalt to aggregates, pavement surfaces, and other materials, ultimately increasing the durability and longevity of the asphalt pavement. However, in order for these adhesion promoters to be effective, it is essential to ensure that they are compatible with the specific type of asphalt being used.

Compatibility testing for asphalt adhesion promoters and asphalt is a critical step in the construction process, as it helps to determine whether the two materials will work together effectively. This testing involves evaluating the chemical and physical properties of both the adhesion promoter and the asphalt to ensure that they are compatible and will form a strong bond.

One of the main reasons why compatibility testing is so important is that using incompatible materials can lead to a variety of issues, such as poor adhesion, delamination, and premature failure of the pavement. By conducting thorough compatibility testing, construction professionals can identify any potential compatibility issues early on and make any necessary adjustments to ensure that the materials will work together effectively.

There are several methods that can be used to test the compatibility of asphalt adhesion promoters and asphalt. One common method is to perform a bond strength test, which involves applying the adhesion promoter to a sample of asphalt and then measuring the force required to pull the two materials apart. This test can help to determine whether the adhesion promoter is able to effectively bond with the asphalt and provide the desired level of adhesion.

Another method of compatibility testing is to conduct a chemical analysis of both the adhesion promoter and the asphalt to identify any potential compatibility issues. This analysis can help to determine whether the two materials are chemically compatible and will not react negatively with each other when combined.

In addition to bond strength tests and chemical analysis, it is also important to consider the physical properties of the adhesion promoter and asphalt when conducting compatibility testing. Factors such as viscosity, curing time, and temperature resistance can all impact the compatibility of the two materials and should be taken into account during testing.

Overall, compatibility testing for asphalt adhesion promoters and asphalt is a crucial step in the construction process that should not be overlooked. By ensuring that these materials are compatible, construction professionals can help to prevent issues such as poor adhesion and premature pavement failure, ultimately leading to a more durable and long-lasting asphalt pavement.

In conclusion, compatibility testing for asphalt adhesion promoters and asphalt is an essential part of the construction process that can help to ensure the success of a project. By carefully evaluating the chemical and physical properties of these materials, construction professionals can identify any potential compatibility issues early on and make any necessary adjustments to ensure that the materials will work together effectively. Ultimately, this can help to create a stronger, more durable asphalt pavement that will stand the test of time.