Table of Contents

Benefits of Using Low Carbon Black Iron Pipe ERW Steel Tubes

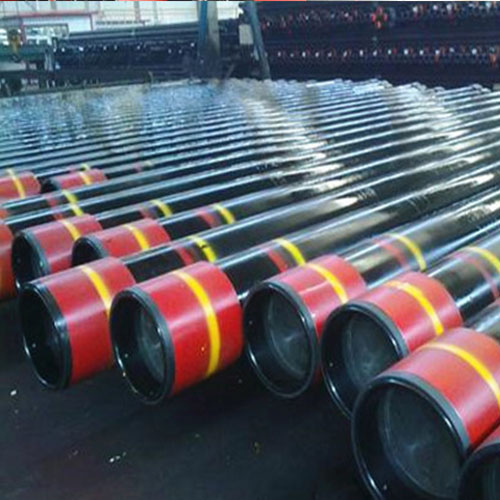

Low carbon black iron pipe ERW steel tubes are a popular choice in various industries due to their high quality and durability. These pipes are made from Carbon Steel, which is known for its strength and resistance to corrosion. ERW stands for Electric Resistance Welding, a process that involves the use of electricity to create a strong bond between the steel sheets. This results in a seamless and uniform pipe that is ideal for a wide range of applications.

One of the key benefits of using low carbon black iron pipe ERW steel tubes is their high quality. These pipes are manufactured to meet strict industry standards, ensuring that they are strong, durable, and reliable. This makes them an excellent choice for applications where strength and durability are essential, such as in construction, oil and gas, and automotive industries.

Another advantage of low carbon black iron pipe ERW steel tubes is their low carbon content. This makes them environmentally friendly and reduces their carbon footprint. By using low carbon steel, manufacturers can help reduce greenhouse gas emissions and contribute to a more sustainable future. Additionally, low carbon steel is easier to recycle, making it a more environmentally friendly option compared to other materials.

In addition to their high quality and low carbon content, low carbon black iron pipe ERW steel tubes are also lightweight and easy to install. This makes them a cost-effective option for a wide range of applications, as they require less labor and equipment to install compared to other types of pipes. Their lightweight nature also makes them easier to transport, reducing shipping costs and making them a more convenient option for manufacturers and contractors.

Furthermore, low carbon black iron pipe ERW steel tubes are highly versatile and can be used in a variety of applications. They are commonly used in plumbing, heating, ventilation, and Air Conditioning Systems, as well as in structural and mechanical applications. Their strength and durability make them suitable for high-pressure and high-temperature environments, making them a reliable choice for a wide range of industries.

Overall, low carbon black iron pipe ERW steel tubes offer a range of benefits that make them an excellent choice for a wide range of applications. Their high quality, low carbon content, lightweight nature, and versatility make them a cost-effective and environmentally friendly option for manufacturers and contractors. By choosing low carbon black iron pipe ERW steel tubes, businesses can benefit from a durable and reliable product that meets their needs while also contributing to a more sustainable future.

Comparison of High Quality ERW Steel Pipe vs. ERW Seamless Weight of Ms Square Steel Tubular

Low carbon black iron pipe ERW steel tubes/tubular carbon Steel Pipes are essential components in various industries, including construction, manufacturing, and infrastructure development. These pipes are known for their durability, strength, and versatility, making them a popular choice for a wide range of applications. In this article, we will compare high-quality ERW steel pipes with ERW seamless weight of MS square steel tubular to help you understand the differences between the two and make an informed decision when choosing the right type of pipe for your project.

ERW (Electric Resistance Welding) steel pipes are made by rolling a steel plate or coil into a cylindrical shape and then welding the edges together using a high-frequency electric current. This process results in a strong and durable pipe that is suitable for various applications. On the other hand, ERW seamless weight of MS square steel tubular is made by piercing a solid steel billet to create a seamless tube without any welding. This seamless construction provides a higher level of strength and reliability compared to ERW steel pipes.

https://youtube.com/watch?v=mlDSyUP5RK0

One of the key differences between high-quality ERW steel pipes and ERW seamless weight of MS square steel tubular is their manufacturing process. While both types of pipes are made using high-quality steel, the seamless construction of MS square steel tubular provides a higher level of structural integrity and resistance to pressure and corrosion. This makes seamless pipes ideal for applications where strength and durability are critical, such as in the oil and gas industry or in high-pressure hydraulic systems.

In terms of cost, ERW steel pipes are generally more affordable than seamless pipes due to their simpler manufacturing process. However, the initial cost savings of ERW steel pipes may be offset by the need for additional maintenance and repairs over time. On the other hand, ERW seamless weight of MS square steel tubular requires less maintenance and has a longer lifespan, making it a cost-effective choice in the long run.

When it comes to performance, both high-quality ERW steel pipes and ERW seamless weight of MS square steel tubular offer excellent strength and durability. However, seamless pipes have a smoother interior surface, which reduces friction and allows for better flow of fluids and gases. This makes seamless pipes ideal for applications where a high level of precision and efficiency is required, such as in the automotive or aerospace industries.

In conclusion, both high-quality ERW steel pipes and ERW seamless weight of MS square steel tubular have their own unique advantages and applications. While ERW steel pipes are more affordable and suitable for general-purpose use, seamless pipes offer superior strength, durability, and performance in demanding applications. When choosing between the two types of pipes, it is important to consider your specific requirements and budget to make the right decision for your project. Whether you choose high-quality ERW steel pipes or ERW seamless weight of MS square steel tubular, you can be confident that you are investing in a reliable and durable pipe that will meet your needs for years to come.