Table of Contents

Benefits of Using Liquid Bonding Agent in Asphalt Pavement Construction

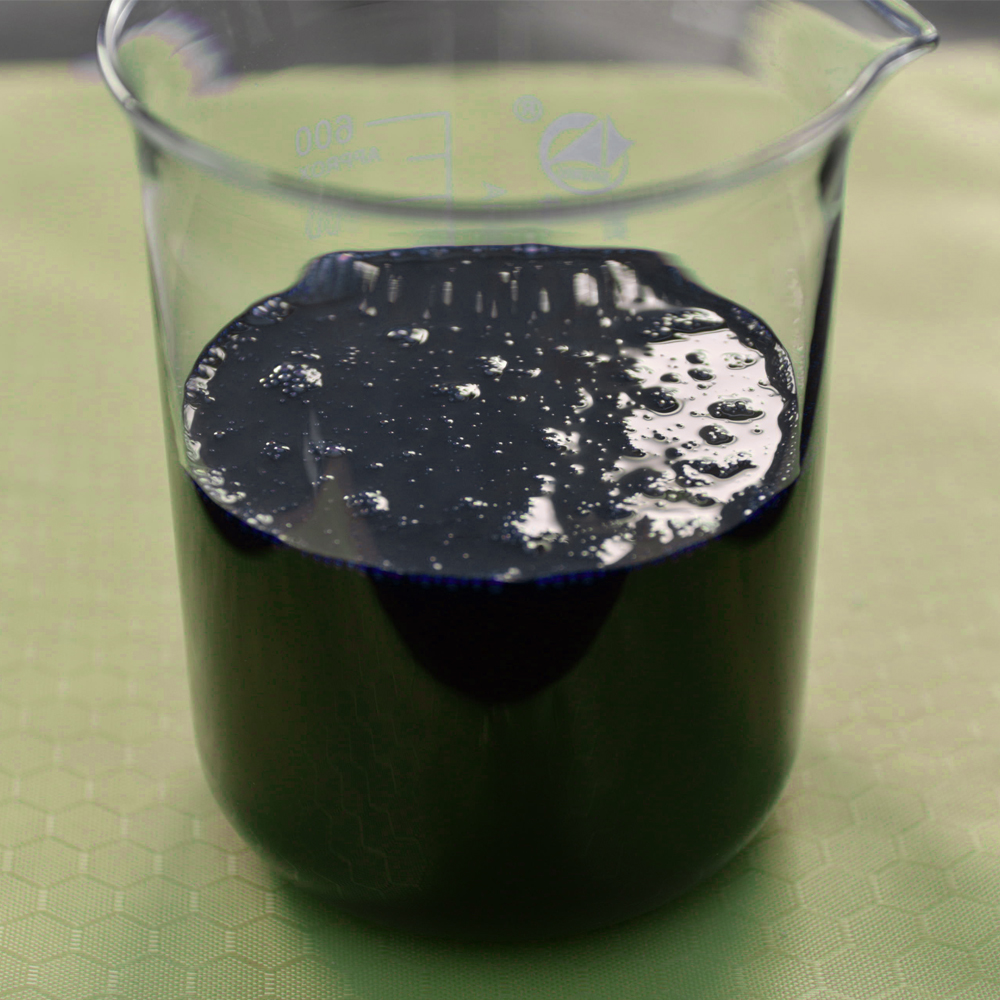

Liquid bonding agents are a crucial component in asphalt pavement construction, providing numerous benefits that contribute to the longevity and durability of the pavement. One such liquid bonding agent is the anti-strip asphalt additive, which helps prevent moisture damage and enhances the adhesion between asphalt binder and aggregate. In this article, we will explore the benefits of using liquid bonding agents, specifically the anti-strip asphalt additive, in asphalt pavement construction.

One of the primary benefits of using a liquid bonding agent in asphalt pavement construction is improved adhesion between the asphalt binder and aggregate. The anti-strip asphalt additive works by chemically modifying the asphalt binder to enhance its bonding properties, ensuring a strong and durable bond between the binder and aggregate. This improved adhesion helps prevent stripping, which is a common issue in asphalt pavements where the binder fails to adhere to the aggregate, leading to premature pavement failure.

In addition to enhancing adhesion, liquid bonding agents also help improve the overall performance of the asphalt pavement. By ensuring a strong bond between the binder and aggregate, the pavement is better able to withstand the stresses and strains of traffic and environmental factors. This results in a longer-lasting pavement that requires less maintenance and repair over its lifespan, ultimately saving time and money for both contractors and road agencies.

Another benefit of using liquid bonding agents in asphalt pavement construction is their ability to reduce moisture damage. Moisture is one of the leading causes of pavement deterioration, as it can weaken the bond between the binder and aggregate and Lead to cracking and rutting. The anti-strip asphalt additive helps seal out moisture, preventing it from penetrating the pavement and causing damage. This not only extends the life of the pavement but also reduces the need for costly repairs and replacements.

Furthermore, liquid bonding agents can improve the workability of the asphalt mix, making it easier to handle and compact during construction. This results in a smoother and more uniform pavement surface, which enhances ride quality and reduces noise Levels for motorists. Additionally, the improved workability of the mix can help reduce construction time and labor costs, making the overall construction process more efficient and cost-effective.

Overall, the benefits of using liquid bonding agents, such as the anti-strip asphalt additive, in asphalt pavement construction are clear. From improving adhesion and performance to reducing moisture damage and enhancing workability, these agents play a crucial role in ensuring the longevity and durability of asphalt pavements. By incorporating liquid bonding agents into their construction practices, contractors and road agencies can create high-quality pavements that provide safe and smooth driving surfaces for years to come.

Importance of Understanding MSDS for Anti-Strip Asphalt Additives

In the construction industry, asphalt is a commonly used material for paving roads, parking lots, and other surfaces. To enhance the performance of asphalt, anti-strip additives are often used to improve the adhesion between the asphalt binder and the aggregate. One such additive is a liquid bonding agent, which is designed to prevent stripping and moisture damage in asphalt pavements.

Before using any chemical product, it is essential to understand its properties, potential hazards, and safe handling procedures. This is where Material Safety Data Sheets (MSDS) come into play. An MSDS provides detailed information about a chemical product, including its composition, physical and chemical properties, health hazards, and safety precautions. For liquid bonding agents used as anti-strip additives in asphalt, understanding the MSDS is crucial for ensuring the safety of workers and the quality of the final product.

| Nr. | Article Name |

| 1 | asphalt bonding agent agent |

One of the key reasons why understanding the MSDS for anti-strip asphalt additives is important is to protect the health and safety of workers. Liquid bonding agents may contain hazardous Chemicals that can pose risks to those who handle them. By reviewing the MSDS, workers can identify potential hazards, such as skin irritation, respiratory problems, or chemical burns, and take appropriate precautions to minimize the risks. This may include wearing Personal Protective Equipment, such as gloves, goggles, or respirators, and following safe handling procedures.

In addition to protecting workers’ health, understanding the MSDS for anti-strip asphalt additives is essential for ensuring the quality and performance of the final product. The composition of the bonding agent, its compatibility with the asphalt binder, and the recommended application rates can all impact the effectiveness of the additive in preventing stripping and improving adhesion. By reviewing the MSDS, contractors and engineers can make informed decisions about the selection and use of anti-strip additives to achieve the desired performance and durability of the asphalt pavement.

Furthermore, the MSDS provides valuable information about the environmental impact of anti-strip asphalt additives. Some liquid bonding agents may contain chemicals that are harmful to the Environment if not handled properly. By understanding the environmental hazards associated with these additives, contractors can take steps to minimize their impact on air, water, and soil quality during storage, handling, and disposal. This may include implementing spill prevention measures, using containment systems, or following proper waste management practices.

In conclusion, understanding the MSDS for anti-strip asphalt additives, such as liquid bonding agents, is essential for protecting the health and safety of workers, ensuring the quality and performance of the final product, and minimizing the environmental impact of these chemicals. By reviewing the MSDS and following the recommended safety precautions, contractors and engineers can make informed decisions about the selection, handling, and disposal of anti-strip additives to achieve safe and sustainable asphalt pavements.