Table of Contents

Benefits of Using a Labeling Machine for Your Products

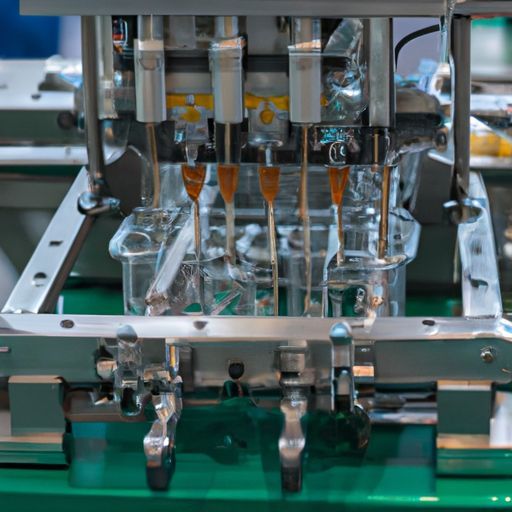

In today’s fast-paced world of manufacturing and production, efficiency is key. One way to streamline your production process and ensure consistency in your product labeling is by investing in a labeling machine. Labeling Machines are automated systems that apply labels to products quickly and accurately, saving time and reducing the risk of human error. There are many benefits to using a labeling machine for your products, from increased productivity to improved brand image.

One of the primary benefits of using a labeling machine is the speed at which labels can be applied to products. Manual labeling can be a time-consuming and labor-intensive process, especially for companies with high production volumes. A labeling machine can apply labels to products at a much faster rate than manual labeling, allowing you to increase your output and meet tight deadlines more easily.

In addition to speed, labeling machines also offer a high level of accuracy and consistency. Human error is always a risk when it comes to manual labeling, but with a labeling machine, you can ensure that each label is applied in the exact same position every time. This level of consistency is important for maintaining a professional brand image and ensuring that your products meet quality standards.

Another benefit of using a labeling machine is the versatility it offers. Labeling machines can be customized to accommodate a wide range of product sizes and shapes, making them suitable for a variety of industries. Whether you are labeling bottles, jars, boxes, or tubes, a labeling machine can be tailored to meet your specific needs.

In addition to speed, accuracy, and versatility, labeling machines also offer cost savings in the long run. While there is an initial investment required to purchase a labeling machine, the time and labor savings it provides can quickly offset this cost. By automating the labeling process, you can reduce the need for manual labor and free up your employees to focus on other tasks.

Furthermore, using a labeling machine can also help to reduce waste. Manual labeling can result in misaligned or wrinkled labels, which may need to be discarded and replaced. With a labeling machine, you can ensure that each label is applied correctly the first time, reducing the amount of wasted materials and saving you money in the long run.

Overall, investing in a labeling machine for your products can offer a wide range of benefits, from increased productivity and accuracy to cost savings and reduced waste. By automating the labeling process, you can streamline your production process and ensure that your products are consistently labeled to the highest standards. Whether you are a small business looking to improve efficiency or a large manufacturer seeking to increase output, a labeling machine can help you achieve your goals and take your business to the next level.