Table of Contents

The Importance of Proper Tube and Casing Selection in Oil and Gas Wells

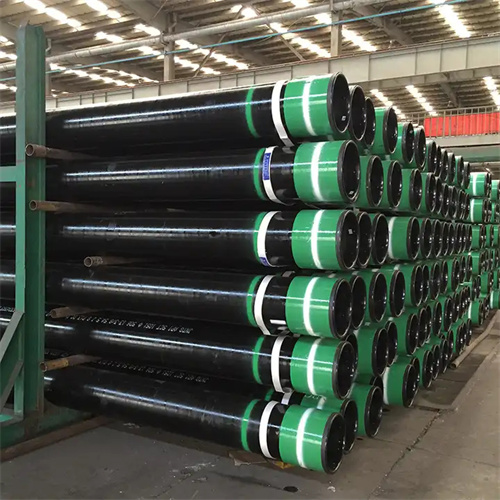

Tube and casing are essential components in the construction of oil and gas wells. They play a crucial role in ensuring the integrity and efficiency of the well, as well as protecting the surrounding Environment. Proper selection of tube and casing is vital to the success of a well, as it can impact production rates, well longevity, and overall Safety.

When it comes to selecting tube and casing for an oil or gas well, there are several factors that must be taken into consideration. One of the most important factors is the depth of the well. Deeper wells require stronger and more durable tube and casing to withstand the higher pressures and temperatures that are present at greater depths. Additionally, the type of formation that the well is being drilled into must also be considered. Different formations have different characteristics, such as hardness and porosity, which can impact the type of tube and casing that is needed.

Another important consideration when selecting tube and casing is the type of fluids that will be produced from the well. Some fluids, such as corrosive or abrasive substances, can cause damage to the tube and casing if they are not properly protected. In these cases, special coatings or materials may be required to ensure the longevity of the tube and casing.

In addition to the type of fluids being produced, the pressure and temperature conditions of the well must also be taken into account when selecting tube and casing. Wells that are subject to high pressures and temperatures require tube and casing that can withstand these extreme conditions without failing. Failure of the tube and casing can result in costly repairs, production delays, and even environmental damage.

Proper selection of tube and casing is not only important for the success of the well, but also for the safety of the workers and the surrounding environment. Tube and casing that are not properly selected or installed can Lead to catastrophic failures, such as blowouts or leaks, which can have devastating consequences. By choosing the right tube and casing for the specific conditions of the well, operators can minimize the risk of these types of incidents and ensure the safety of everyone involved.

In conclusion, proper selection of tube and casing is crucial for the success of oil and gas wells. By considering factors such as well depth, formation type, fluid characteristics, pressure and temperature conditions, operators can choose the right tube and casing to ensure the integrity and efficiency of the well. Additionally, selecting the proper tube and casing is essential for the safety of workers and the surrounding environment. By taking the time to carefully select the right tube and casing for each well, operators can minimize risks, maximize production rates, and ensure the longevity of the well.