Table of Contents

Benefits of Using High Modulus Agent for Driveway Rutting Resistance

Driveways are an essential part of any property, providing a safe and convenient way to access homes and businesses. However, over time, driveways can become susceptible to wear and tear, especially in areas with heavy traffic. One common issue that many property owners face is driveway rutting, which occurs when the surface of the driveway becomes uneven and develops depressions or ruts. This not only affects the appearance of the driveway but also poses a Safety hazard for vehicles and pedestrians.

To address this issue, many property owners are turning to high modulus agents as a solution for driveway rutting resistance. These additives are designed to improve the strength and durability of the driveway surface, making it more resistant to rutting and other forms of damage. By incorporating high modulus agents into the construction or maintenance of a driveway, property owners can enjoy a range of benefits that contribute to the longevity and performance of their driveway.

One of the key benefits of using high modulus agents for driveway rutting resistance is improved stability. These additives help to increase the stiffness and strength of the driveway surface, preventing it from deforming under the weight of vehicles or the pressure of heavy traffic. This enhanced stability not only reduces the likelihood of rutting but also helps to maintain a smooth and even surface, making it easier and safer to drive on.

In addition to stability, high modulus agents also offer increased durability. By strengthening the driveway surface, these additives help to protect it from the effects of wear and tear, such as cracking, crumbling, or erosion. This can significantly extend the lifespan of the driveway, reducing the need for costly repairs or replacements in the future. With proper maintenance and care, a driveway treated with high modulus agents can remain in good condition for many years to come.

Furthermore, high modulus agents can also improve the overall performance of the driveway. By enhancing its strength and durability, these additives can help to reduce the risk of damage from factors such as heavy loads, extreme weather conditions, or chemical exposure. This not only ensures the longevity of the driveway but also enhances its functionality, making it a reliable and safe surface for vehicles and pedestrians to use.

Another benefit of using high modulus agents for driveway rutting resistance is cost-effectiveness. While the initial investment may be higher compared to traditional construction methods, the long-term savings can be significant. By reducing the need for frequent repairs or replacements, property owners can save money on maintenance costs and prolong the lifespan of their driveway, ultimately providing a better return on investment.

Overall, high modulus agents offer a range of benefits for property owners looking to improve the durability and performance of their driveways. From increased stability and durability to enhanced performance and cost-effectiveness, these additives provide a reliable solution for addressing driveway rutting and ensuring a long-lasting and functional surface. By incorporating high modulus agents into the construction or maintenance of their driveways, property owners can enjoy a range of advantages that contribute to the overall quality and value of their property.

How to Choose the Right Driveway Rutting Resistance Additives for Your Project

When it comes to choosing the right driveway rutting resistance additives for your project, one of the most important factors to consider is the use of High Modulus Agents. These additives are specifically designed to improve the stiffness and strength of asphalt pavements, making them more resistant to rutting and other forms of distress. In this article, we will explore the benefits of using High Modulus Agents in your driveway construction projects and provide some tips on how to select the best additive for your specific needs.

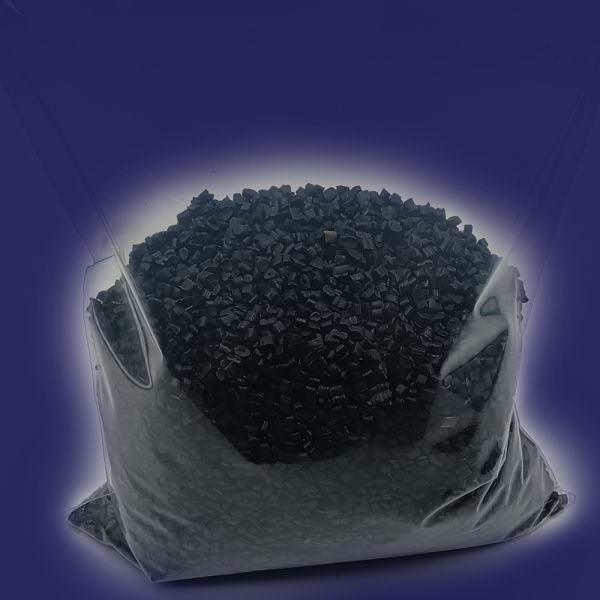

High Modulus Agents are typically made from polymers or fibers that are added to the asphalt mix during the production process. These additives work by increasing the stiffness of the asphalt binder, which helps to distribute loads more evenly across the pavement surface. This, in turn, reduces the likelihood of rutting and other forms of deformation that can occur under heavy traffic loads. High Modulus Agents are particularly effective in areas with high traffic volumes or where heavy trucks are common, as they help to improve the overall durability and longevity of the pavement.

One of the key benefits of using High Modulus Agents is their ability to improve the fatigue resistance of asphalt pavements. Fatigue cracking is a common form of distress that occurs when repeated loading causes the pavement to crack and break apart. By increasing the stiffness of the asphalt binder, High Modulus Agents help to reduce the likelihood of fatigue cracking, leading to a longer-lasting and more durable pavement surface. This can result in significant cost savings over the life of the pavement, as maintenance and repair costs are reduced.

When selecting a High Modulus Agent for your project, it is important to consider the specific requirements of your pavement design and the expected traffic loads. Different types of additives have varying Levels of stiffness and strength, so it is important to choose an additive that is compatible with your asphalt mix and construction methods. Additionally, some High Modulus Agents may require special equipment or application techniques, so be sure to consult with a qualified engineer or contractor before making a final decision.

In addition to improving the rutting resistance of asphalt pavements, High Modulus Agents can also help to reduce the overall thickness of the pavement structure. This can result in cost savings during construction, as less material is required to achieve the desired performance characteristics. By using High Modulus Agents, you can create a more sustainable and environmentally friendly pavement design that meets the needs of your project while minimizing the use of natural resources.

In conclusion, High Modulus Agents are a valuable tool for improving the rutting resistance of asphalt pavements and enhancing the overall durability and longevity of the pavement surface. By selecting the right additive for your project and following best practices for application and construction, you can create a high-quality pavement that will stand up to the demands of heavy traffic and harsh environmental conditions. Consider using High Modulus Agents in your next driveway construction project to ensure a long-lasting and cost-effective pavement solution.

| Nr. | Item |

| 1 | Rut Resistance Additive for Road maintenance |