Table of Contents

Benefits of Using Wood Cellulose Fibers in Chinese Manufacturing

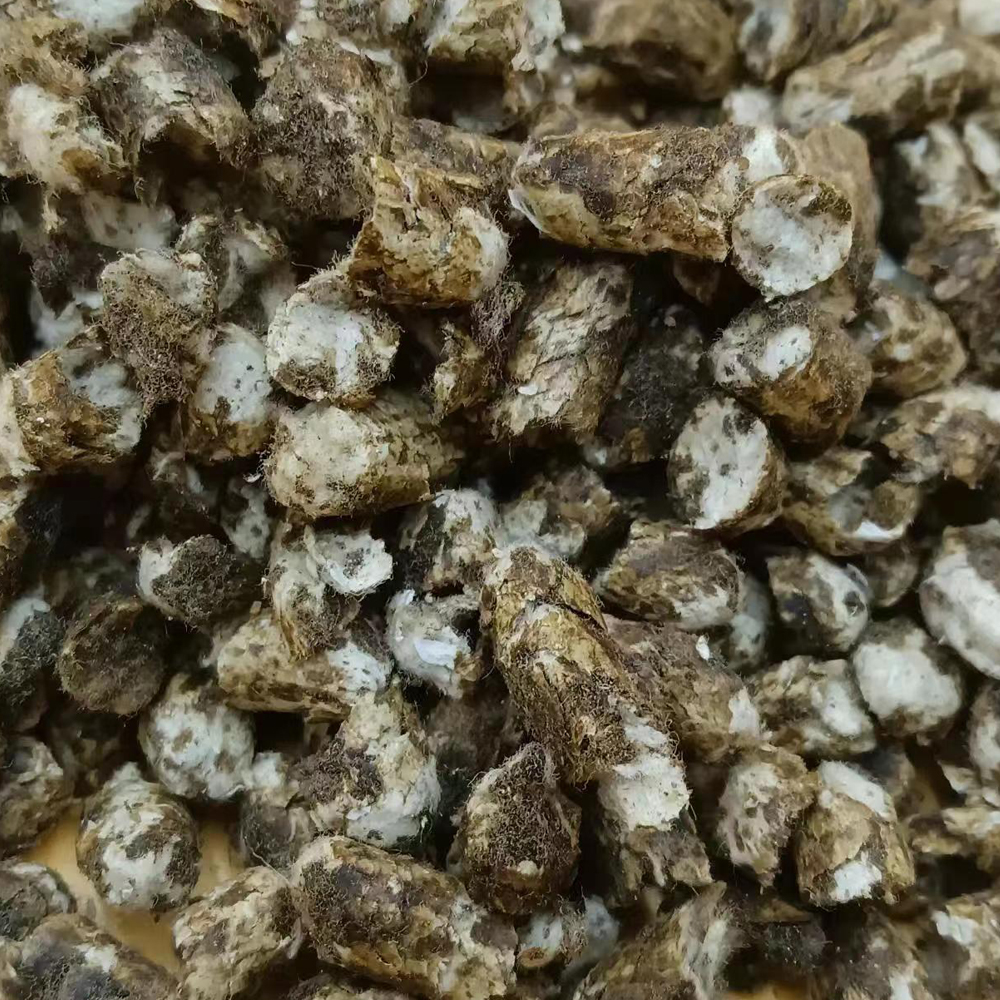

Wood cellulose fibers have long been used in various industries for their versatility and eco-friendly properties. In recent years, Chinese manufacturers have emerged as some of the leading exporters of wood cellulose fibers, offering high-quality products that meet the demands of a global market. There are several benefits to using wood cellulose fibers in Chinese manufacturing, ranging from their sustainability to their superior performance in a wide range of applications.

One of the key advantages of using wood cellulose fibers in Chinese manufacturing is their sustainability. As the demand for eco-friendly products continues to grow, manufacturers are increasingly turning to renewable resources like wood cellulose fibers to reduce their environmental impact. These fibers are derived from wood Pulp, a renewable resource that can be sustainably harvested and processed to create a wide range of products. By using wood cellulose fibers, Chinese manufacturers can reduce their reliance on non-renewable resources and help protect the Environment for future generations.

In addition to their sustainability, wood cellulose fibers offer superior performance in a variety of applications. These fibers are known for their strength, durability, and versatility, making them ideal for use in a wide range of products, from paper and textiles to plastics and composites. Chinese manufacturers have honed their production processes to create high-quality wood cellulose fibers that meet the stringent requirements of global markets. Whether used as a reinforcement in plastics or as a filler in paper products, wood cellulose fibers offer superior performance and durability compared to traditional materials.

Furthermore, wood cellulose fibers are biodegradable, making them an attractive option for manufacturers looking to reduce their environmental footprint. Unlike synthetic fibers, which can take hundreds of years to break Down in the environment, wood cellulose fibers are easily biodegradable and can be composted or recycled at the end of their life cycle. This makes them an ideal choice for manufacturers looking to create sustainable products that minimize waste and pollution.

Another benefit of using wood cellulose fibers in Chinese manufacturing is their cost-effectiveness. As the demand for eco-friendly products continues to grow, manufacturers are looking for cost-effective solutions that meet their sustainability goals. Wood cellulose fibers offer a cost-effective alternative to traditional materials, providing manufacturers with a sustainable option that does not compromise on quality or performance. Chinese manufacturers have invested in state-of-the-art production facilities to create high-quality wood cellulose fibers at competitive prices, making them an attractive option for businesses looking to reduce their production costs without sacrificing quality.

In conclusion, the use of wood cellulose fibers in Chinese manufacturing offers a wide range of benefits, from their sustainability and superior performance to their cost-effectiveness. Chinese manufacturers have emerged as some of the leading exporters of wood cellulose fibers, offering high-quality products that meet the demands of a global market. By using wood cellulose fibers, manufacturers can create sustainable products that reduce their environmental impact while also benefiting from the superior performance and cost-effectiveness of these versatile fibers. As the demand for eco-friendly products continues to grow, wood cellulose fibers are poised to play a key role in the future of manufacturing, providing a sustainable and cost-effective solution for businesses around the world.

How Chinese Exporters Can Improve the Quality of Wood Cellulose Fiber Products

Wood cellulose fibers are a versatile material that is used in a wide range of industries, from paper and textiles to pharmaceuticals and food products. Chinese exporters play a significant role in the global market for wood cellulose fibers, but there is always room for improvement when it comes to the quality of their products. By focusing on key areas such as production processes, quality control, and customer service, Chinese exporters can enhance the value of their wood cellulose fiber products and better meet the needs of their customers.

One of the most important ways that Chinese exporters can improve the quality of their wood cellulose fiber products is by paying close attention to their production processes. This includes everything from sourcing high-quality raw materials to using state-of-the-art equipment and technology to ensure that the fibers are processed efficiently and effectively. By investing in modern production techniques and equipment, Chinese exporters can increase the consistency and purity of their wood cellulose fibers, resulting in a higher-quality end product that is more attractive to customers.

In addition to improving their production processes, Chinese exporters should also focus on implementing rigorous quality control measures to ensure that their wood cellulose fiber products meet the highest standards. This includes conducting regular inspections and tests throughout the production process to identify any potential issues or defects and address them promptly. By maintaining strict quality control standards, Chinese exporters can minimize the risk of product recalls or returns and build a reputation for reliability and consistency in the market.

Another key area where Chinese exporters can improve the quality of their wood cellulose fiber products is by providing exceptional customer service. This includes offering personalized support and assistance to customers, responding promptly to inquiries and concerns, and being proactive in addressing any issues that may arise. By building strong relationships with their customers and demonstrating a commitment to meeting their needs, Chinese exporters can differentiate themselves from competitors and build a loyal customer base that values the quality and reliability of their products.

| Part | Products |

| 1 | Wood pulp fibers |

Furthermore, Chinese exporters can enhance the value of their wood cellulose fiber products by investing in research and development to explore new applications and uses for the material. By staying at the forefront of innovation and technology, Chinese exporters can develop new products and solutions that meet the evolving needs of their customers and open up new opportunities for growth and expansion in the market. By continuously seeking ways to improve and innovate, Chinese exporters can position themselves as leaders in the wood cellulose fiber industry and drive long-term success and sustainability.

In conclusion, Chinese exporters have a significant opportunity to improve the quality of their wood cellulose fiber products by focusing on key areas such as production processes, quality control, customer service, and research and development. By investing in these areas and demonstrating a commitment to excellence and innovation, Chinese exporters can enhance the value of their products, build strong relationships with customers, and drive long-term success in the global market for wood cellulose fibers. By taking proactive steps to improve the quality of their products, Chinese exporters can position themselves as leaders in the industry and create a competitive advantage that sets them apart from their peers.