Table of Contents

Avantages de l’utilisation de tubes tressés industriels pour la distribution d’air, de pétrole, d’eau et de gaz à haute pression

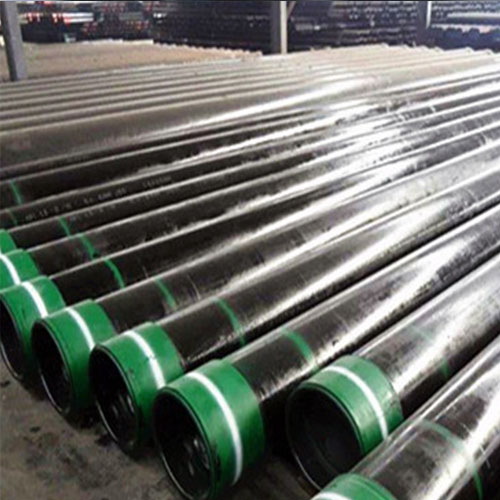

Dans l’ensemble, les avantages de l’utilisation de tubes tressés industriels pour l’acheminement de l’air, du pétrole, de l’eau et du gaz à haute pression sont nombreux. Ces tubes offrent durabilité, flexibilité, résistance aux pressions élevées et résistance à la température, ce qui en fait un choix idéal pour une large gamme d’applications industrielles. Qu’ils soient utilisés dans la fabrication, la construction ou dans d’autres contextes industriels, les tubes tressés industriels constituent un moyen fiable et efficace de transport de fluides et de gaz. Leur capacité à résister aux rigueurs des environnements industriels en fait un élément essentiel pour garantir la livraison sûre et efficace de fluides et de gaz dans diverses industries.

In addition to their durability, industrial braided tubes are also highly flexible. This flexibility allows the tubes to be easily maneuvered and installed in tight spaces, making them ideal for use in a variety of industrial settings. The flexibility of these tubes also allows for easy routing around Obstacles, ensuring that fluids and gases can be delivered efficiently and effectively. This flexibility is essential in industrial applications where space is limited, and the ability to navigate tight corners and bends is necessary.

Another key benefit of using industrial braided tubes is their resistance to high pressures. These tubes are designed to withstand the extreme pressures that are often encountered in industrial applications, making them an ideal choice for the delivery of high-pressure gases and fluids. The braided design of these tubes provides added strength and reinforcement, ensuring that they can safely transport fluids and gases at high pressures without the risk of failure. This resistance to high pressures is essential in industries where the safe and efficient delivery of fluids and gases is critical.

Furthermore, industrial braided tubes are also resistant to temperature extremes, making them suitable for use in a wide range of industrial environments. These tubes can withstand both high and low temperatures, ensuring that they can perform reliably in a variety of conditions. This temperature resistance is essential in industries where extreme temperatures are common, ensuring that the tubes can maintain their integrity and performance even in the harshest of environments.

Overall, the benefits of using industrial braided tubes for air, oil, water, and high-pressure gas delivery are numerous. These tubes offer durability, flexibility, resistance to high pressures, and temperature resistance, making them an ideal choice for a wide range of industrial applications. Whether used in manufacturing, construction, or other industrial settings, industrial braided tubes provide a reliable and efficient means of Transporting fluids and gases. Their ability to withstand the rigors of industrial environments makes them an essential component in ensuring the safe and efficient delivery of fluids and gases in a variety of industries.