Table of Contents

Exploring the Benefits of Custom Made Cat7 Cable Patch Cord Directly from the Manufacturer

In the realm of network connectivity, the significance of high-quality cables cannot be overstated. Among the various types of cables available in the market, Cat7 cable patch Cords and Cat5e patch cables have gained considerable popularity due to their superior performance and reliability. However, the benefits of these cables can be further enhanced when they are custom made and directly supplied by the manufacturer. This article explores the advantages of procuring custom made Cat7 cable patch cords and Cat5e patch cables directly from the manufacturer.

| Number | Products |

| 1 | Communication Cable |

Firstly, custom made cables offer the advantage of being tailored to meet specific requirements. Every network setup is unique, with different lengths, configurations, and connection points. Custom made Cat7 cable patch cords and Cat5e patch cables can be designed to fit these unique specifications, ensuring optimal performance and reducing the risk of connectivity issues. This level of customization is typically not available with off-the-shelf products, making custom made cables a superior choice for complex network setups.

Secondly, purchasing directly from the manufacturer eliminates the need for middlemen, resulting in cost savings. Manufacturers have the capacity to produce large quantities of cables at a lower cost per unit, which can translate into significant savings for the buyer. Moreover, direct purchases from the manufacturer can also ensure faster delivery times, as there are no intermediaries to slow Down the process.

Thirdly, the quality of custom made cables is often superior to that of mass-produced ones. Manufacturers who specialize in custom made cables typically use high-quality materials and follow stringent quality control processes to ensure that every cable meets the highest standards of performance and durability. This can result in cables that are more reliable, longer-lasting, and less likely to cause network issues.

Furthermore, manufacturers often provide comprehensive after-sales support for their products. This can include technical support, warranty coverage, and assistance with installation and troubleshooting. Such support can be invaluable in ensuring the smooth operation of your network and can save you time and resources in the long run.

Lastly, purchasing custom made Cat7 cable patch cords and Cat5e patch cables directly from the manufacturer can contribute to sustainability. Manufacturers can design and produce cables in a way that minimizes waste and reduces the environmental impact. Moreover, by eliminating the need for transportation and packaging associated with retail sales, direct purchases from the manufacturer can further reduce the carbon footprint of these products.

In conclusion, custom made Cat7 cable patch cords and Cat5e patch cables directly supplied by the manufacturer offer numerous benefits. They can be tailored to meet specific requirements, are often more cost-effective, and typically offer superior quality and after-sales support. Moreover, they can contribute to sustainability by minimizing waste and reducing the environmental impact. Therefore, for those seeking to optimize their network performance while also saving costs and supporting sustainability, purchasing custom made cables directly from the manufacturer is an excellent option.

Understanding the Manufacturing Process of Cat7 Cable Patch Cord Custom Made

The manufacturing process of Cat7 cable patch cord custom made, as well as Cat5e patch cable wires, is a complex and intricate procedure that requires a high level of precision and expertise. These cables, which are directly supplied by manufacturers in China, are essential components in the world of information technology and Telecommunications. They play a crucial role in transmitting data across different devices, making them indispensable in our increasingly digital world.

The production of these cables begins with the selection of high-quality raw materials. The Cat7 cable, for instance, is made from four twisted pairs of Copper wires, each wrapped in a layer of high-density polyethylene insulation. This design not only enhances the cable’s performance but also provides superior protection against external interference. The Cat5e patch cable, on the other hand, is made from four pairs of copper wires, each pair twisted together to reduce crosstalk and noise interference.

Once the raw materials are selected, the next step in the manufacturing process involves the precise cutting of these materials. The copper wires are cut to the exact length required for the specific type of cable being produced. This is a critical step as the length of the wire can significantly impact the cable’s performance. Too long, and the signal may degrade; too short, and the cable may not reach its intended destination.

| Nr. | Product |

| 1 | crossover cable |

After the wires are cut, they are then twisted together in pairs. This twisting process is crucial in reducing signal interference and enhancing the overall performance of the cable. The number of twists per inch can vary depending on the type of cable being produced. For instance, Cat7 cables typically have more twists per inch compared to Cat5e cables, resulting in higher data transmission rates.

Once the wires are twisted, they are then insulated. This involves wrapping each pair of twisted wires in a layer of high-density polyethylene insulation. This insulation serves two primary purposes: it protects the wires from external interference, and it helps maintain the integrity of the signal being transmitted.

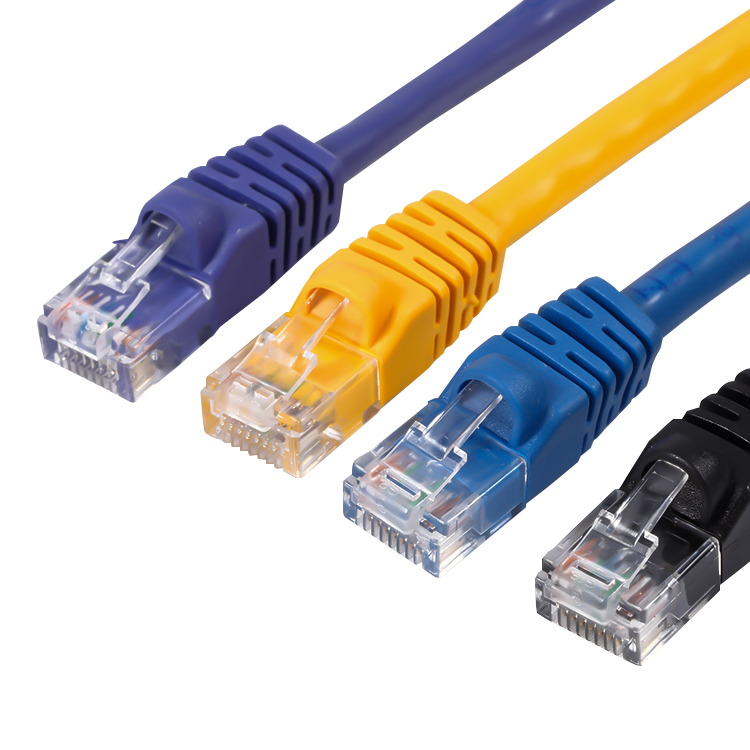

The final step in the manufacturing process involves the assembly of the cable. This includes attaching the Connectors at each end of the cable and testing the cable to ensure it meets the required performance standards. The connectors used for Cat7 and Cat5e cables are typically RJ45 connectors, which are widely used in Ethernet and network cables.

In conclusion, the manufacturing process of Cat7 cable patch cord custom made and Cat5e patch cable wires is a complex procedure that requires a high level of precision and expertise. These cables, which are directly supplied by manufacturers in China, play a crucial role in transmitting data across different devices. Despite their complexity, these cables are relatively affordable, making them a cost-effective solution for businesses and individuals alike. Whether you’re setting up a home network or a large-scale data center, these cables are an essential component in ensuring reliable and efficient data transmission.