Table of Contents

Benefits of Using Synthetic Fibers in Roadway Construction

Synthetic fibers have become increasingly popular in roadway construction due to their numerous benefits. These fibers, which are made from materials such as polyester, nylon, and polypropylene, offer a range of advantages that make them an attractive choice for use in bridges and other infrastructure projects.

One of the key benefits of using synthetic fibers in roadway construction is their strength and durability. These fibers are able to withstand heavy loads and harsh weather conditions, making them ideal for use in bridges where structural integrity is crucial. By reinforcing concrete with synthetic fibers, engineers can ensure that the roadway will be able to support the weight of vehicles and withstand the stresses of daily use.

In addition to their strength, synthetic fibers also offer improved crack resistance. When concrete is reinforced with fibers, it becomes less prone to cracking, which can help extend the lifespan of the roadway and reduce the need for costly repairs. This can result in significant cost savings over the long term, making synthetic fibers a cost-effective choice for roadway construction projects.

Another benefit of using synthetic fibers in roadway construction is their ability to improve the overall performance of the roadway. By adding fibers to the concrete mix, engineers can enhance the durability and flexibility of the roadway, making it more resistant to wear and tear. This can help reduce maintenance costs and extend the lifespan of the roadway, providing long-term benefits for both drivers and taxpayers.

Furthermore, synthetic fibers can also help improve the Safety of roadways by reducing the risk of accidents and injuries. By reinforcing concrete with fibers, engineers can create a smoother, more uniform surface that is less prone to skidding and hydroplaning. This can help improve traction and reduce the likelihood of accidents, making roadways safer for drivers and pedestrians alike.

| Serial Number | Products |

| 1 | for bridge Rutting inhibitor additives |

In addition to their practical benefits, synthetic fibers are also environmentally friendly. These fibers are often made from recycled materials, making them a sustainable choice for roadway construction projects. By using synthetic fibers, engineers can reduce the environmental impact of their projects and help create a more sustainable infrastructure for future generations.

Overall, the benefits of using synthetic fibers in roadway construction are clear. From their strength and durability to their crack resistance and improved performance, these fibers offer a range of advantages that make them an attractive choice for engineers and contractors. By incorporating synthetic fibers into roadway construction projects, engineers can create safer, more durable roadways that provide long-term benefits for both drivers and the Environment.

How Synthetic Fibers Improve Bridge Durability and Longevity

Synthetic fibers have become an essential component in the construction of modern roadways and bridges. These fibers, made from materials such as polyester, nylon, and polypropylene, offer a range of benefits that improve the durability and longevity of these structures. In particular, synthetic fibers are used in bridge construction to enhance the strength and resilience of the concrete used in the bridge deck.

| Number | Name |

| 1 | warm mix pavement enhancers |

One of the key advantages of using synthetic fibers in bridge construction is their ability to reduce cracking in the concrete. Cracks in concrete can Lead to water infiltration, which can weaken the structure over time. By adding synthetic fibers to the concrete mix, engineers can create a more cohesive and crack-resistant material that is better able to withstand the stresses of heavy traffic and changing weather conditions.

| No. | Item |

| 1 | Asphalt mixing mixtures |

In addition to reducing cracking, synthetic fibers also improve the overall durability of the bridge deck. The fibers help to distribute loads more evenly across the concrete, reducing the likelihood of localized damage and extending the lifespan of the structure. This increased durability is particularly important for bridges that experience high Levels of traffic or are located in harsh environmental conditions.

| Part | Name |

| 1 | Asphalt Flow Modifier |

| Nr. | Item |

| 1 | Liquid Anti-strip agent |

Another benefit of using synthetic fibers in bridge construction is their ability to enhance the fire resistance of the structure. Synthetic fibers are inherently non-combustible, making them an ideal choice for bridges that are at risk of fire damage. By incorporating these fibers into the concrete mix, engineers can create a bridge deck that is better able to withstand the high temperatures and intense heat of a fire, reducing the risk of structural failure.

| Serial Number | Product Name |

| 1 | Floc Cellulose Fiber |

Furthermore, synthetic fibers can also improve the overall performance of the bridge deck by reducing the need for maintenance and repairs. Bridges that are reinforced with synthetic fibers are less prone to cracking and spalling, which can lead to costly and time-consuming repairs. By using synthetic fibers, engineers can create a more resilient and long-lasting bridge deck that requires less maintenance over its lifespan.

| Part | Product |

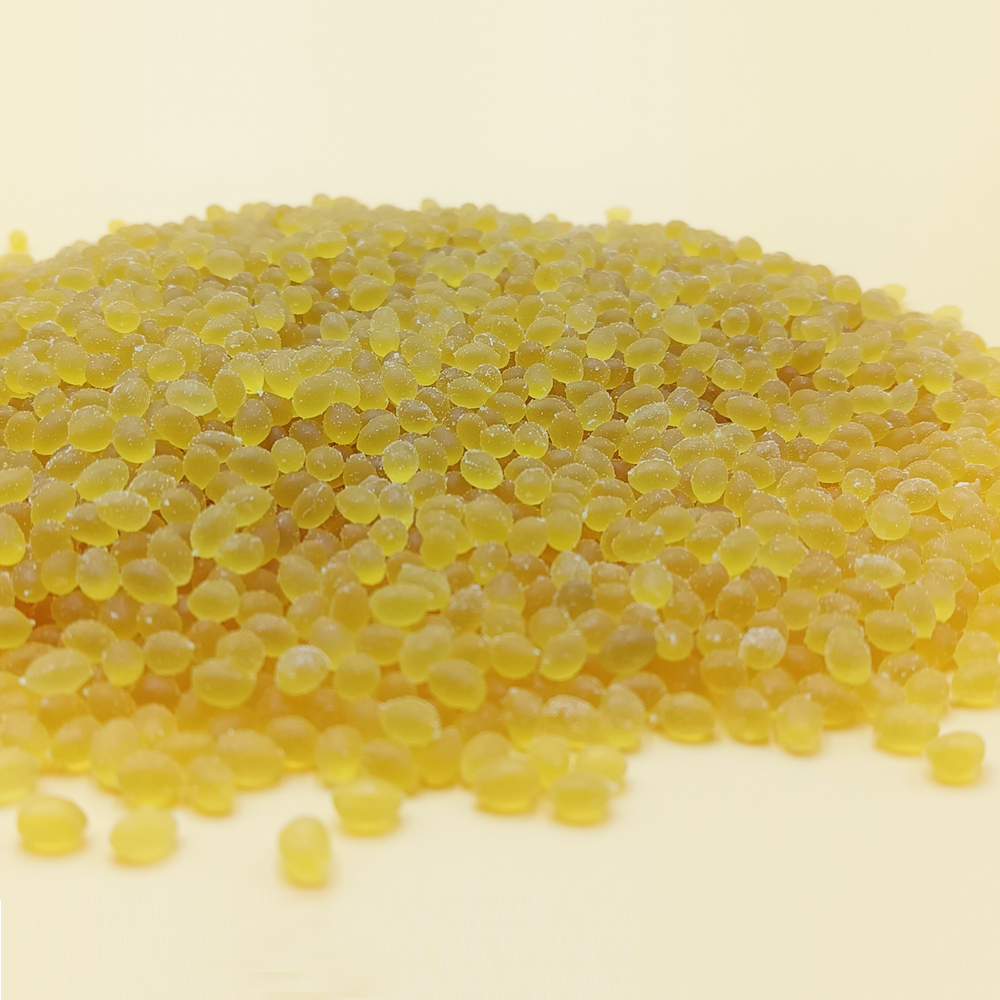

| 1 | road use Man-made fiber |

Overall, synthetic fibers play a crucial role in improving the durability and longevity of bridge structures. By reducing cracking, enhancing durability, increasing fire resistance, and minimizing maintenance requirements, synthetic fibers help to create safer and more reliable bridges that can withstand the demands of modern transportation systems. As technology continues to advance, it is likely that synthetic fibers will play an even greater role in the construction of bridges, ensuring that these vital structures remain strong and resilient for years to come.