Table of Contents

Benefits of Using ASTM A106 A53 Gr. B Steel Standard for Seamless Carbon Steel Pipes

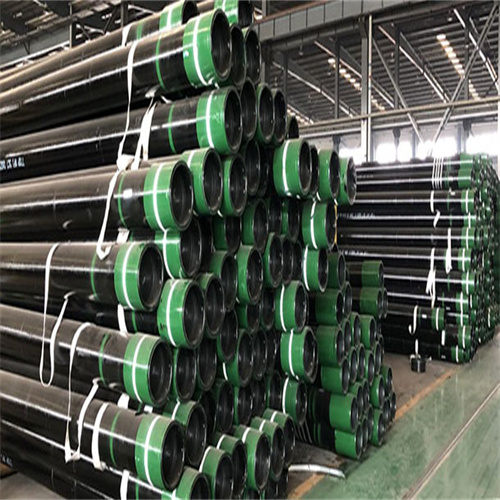

Steel is one of the most widely used materials in various industries due to its strength, durability, and versatility. When it comes to seamless carbon Steel Pipes, the choice of steel standard is crucial in ensuring the quality and performance of the pipes. One of the most commonly used steel standards for seamless carbon steel pipes is ASTM A106 A53 Gr. B.

ASTM A106 A53 Gr. B is a standard specification for seamless carbon steel pipe for high-temperature service. This steel standard is widely recognized for its excellent mechanical properties, including high tensile strength and good weldability. The seamless carbon steel pipes manufactured in accordance with ASTM A106 A53 Gr. B are suitable for a wide range of applications, from oil and gas to petrochemical and power generation industries.

One of the key benefits of using ASTM A106 A53 Gr. B steel standard for seamless carbon steel pipes is its high temperature resistance. These pipes are designed to withstand high temperatures and pressure, making them ideal for applications where extreme conditions are present. Whether it’s Transporting hot fluids or gases, ASTM A106 A53 Gr. B pipes can handle the heat without compromising their structural integrity.

In addition to their high temperature resistance, seamless carbon steel pipes made to ASTM A106 A53 Gr. B standard also offer excellent corrosion resistance. This is essential for applications where the pipes are exposed to corrosive environments, such as in chemical processing plants or offshore oil rigs. The corrosion-resistant properties of ASTM A106 A53 Gr. B pipes ensure long-term durability and reliability, even in harsh conditions.

Another advantage of using ASTM A106 A53 Gr. B steel standard for seamless carbon steel pipes is their uniformity and consistency in quality. The strict manufacturing processes and quality control measures specified in the standard ensure that each pipe meets the required specifications and performance criteria. This consistency in quality not only ensures the reliability of the pipes but also simplifies the installation and maintenance processes.

Furthermore, seamless carbon steel pipes manufactured in accordance with ASTM A106 A53 Gr. B standard are known for their smooth surface finish and precise dimensions. This makes them easy to install and connect, reducing the risk of leaks or failures. The precise dimensions also allow for tight Seals and efficient flow of fluids or gases, improving overall system performance.

In conclusion, ASTM A106 A53 Gr. B steel standard offers a range of benefits for seamless carbon steel pipes, including high temperature resistance, corrosion resistance, uniformity in quality, and precise dimensions. These qualities make ASTM A106 A53 Gr. B pipes a preferred choice for various industrial applications where reliability, durability, and performance are paramount. By choosing seamless carbon steel pipes manufactured to this standard, industries can ensure the long-term success and efficiency of their operations.

Comparison of St37 Carbon Steel and ASTM A106 A53 Gr. B Steel Standards for Seamless Pipes

Steel pipes are an essential component in various industries, including construction, oil and gas, and manufacturing. When it comes to choosing the right type of steel pipe for a specific application, it is crucial to consider the standards that govern their production. Two common standards for seamless carbon steel pipes are St37 and ASTM A106 A53 Gr. B. In this article, we will compare these two standards to help you make an informed decision when selecting a seamless carbon steel pipe for your project.

St37 is a German standard for carbon steel pipes, while ASTM A106 A53 Gr. B is an American standard. Both standards specify the chemical composition, mechanical properties, and testing requirements for seamless carbon steel pipes. One of the key differences between St37 and ASTM A106 A53 Gr. B is the grade of steel used in their production. St37 is a low carbon steel grade, while ASTM A106 A53 Gr. B is a medium carbon steel grade. This difference in carbon content affects the strength and ductility of the steel, as well as its weldability and corrosion resistance.

In terms of mechanical properties, St37 has a minimum yield strength of 235 MPa and a minimum tensile strength of 360-510 MPa. On the other hand, ASTM A106 A53 Gr. B has a minimum yield strength of 240 MPa and a minimum tensile strength of 415 MPa. This means that ASTM A106 A53 Gr. B is slightly stronger than St37, making it a better choice for applications that require higher strength and durability.

Another important factor to consider when comparing St37 and ASTM A106 A53 Gr. B is their chemical composition. St37 contains carbon, manganese, phosphorus, sulfur, and silicon, while ASTM A106 A53 Gr. B contains carbon, manganese, phosphorus, sulfur, and silicon, as well as trace amounts of other elements such as Copper, Nickel, and chromium. The chemical composition of the steel affects its mechanical properties, as well as its weldability and corrosion resistance.

When it comes to testing requirements, both St37 and ASTM A106 A53 Gr. B must undergo various tests to ensure their quality and performance. These tests include chemical analysis, tensile testing, hardness testing, impact testing, and non-destructive testing. By meeting these testing requirements, manufacturers can guarantee that their seamless carbon steel pipes meet the standards set forth by St37 and ASTM A106 A53 Gr. B.

In conclusion, when choosing between St37 and ASTM A106 A53 Gr. B for seamless carbon steel pipes, it is important to consider the grade of steel, mechanical properties, chemical composition, and testing requirements. While both standards have their own strengths and weaknesses, ASTM A106 A53 Gr. B is generally preferred for applications that require higher strength and durability. By understanding the differences between these two standards, you can make an informed decision when selecting a seamless carbon steel pipe for your project.

Installation and Maintenance Tips for Grooved Carbon Steel Pipes with 26 Sch40 Diameter

Steel pipes are a crucial component in various industries, including construction, oil and gas, and manufacturing. When it comes to choosing the right type of steel pipe for your project, it’s essential to consider factors such as material, size, and standards. One popular choice for many applications is the ASTM A106 A53 Gr. B 26″ Sch40 seamless carbon steel grooved pipe.

The ASTM A106 A53 Gr. B standard is one of the most commonly used standards for carbon steel pipes. It specifies the requirements for seamless carbon steel pipe suitable for high-temperature service. The 26″ Sch40 designation refers to the size and schedule of the pipe, with a 26-inch diameter and a schedule 40 thickness. This size and schedule combination is ideal for applications that require a balance of strength and flow capacity.

One of the key advantages of grooved carbon steel pipes is their ease of installation. The grooved ends of the pipe allow for quick and secure connections using grooved couplings. This eliminates the need for welding or threading, saving time and labor costs during installation. Additionally, grooved pipes can accommodate movement and vibration, making them suitable for applications where flexibility is required.

When installing grooved carbon steel pipes, it’s essential to follow best practices to ensure a secure and leak-free connection. Start by preparing the pipe ends by removing any burrs or debris. Next, apply a thin layer of lubricant to the grooves to facilitate assembly. Slide the grooved couplings onto the pipe ends and align them properly before tightening the Bolts to the recommended torque.

Proper maintenance is crucial to ensure the longevity and performance of grooved carbon steel pipes. Regular inspections should be conducted to check for signs of corrosion, leaks, or damage. Any issues should be addressed promptly to prevent further deterioration. Additionally, it’s important to follow the manufacturer’s recommendations for cleaning and maintenance to prevent buildup and blockages.

In conclusion, the ASTM A106 A53 Gr. B 26″ Sch40 seamless carbon steel grooved pipe is a reliable and versatile choice for various applications. Its adherence to industry standards ensures quality and performance, while its grooved design allows for easy installation and maintenance. By following best practices for installation and maintenance, you can maximize the lifespan and efficiency of grooved carbon steel pipes in your project.