Table of Contents

Benefits of Using Extraction SCF Machine for Motor Oil Production

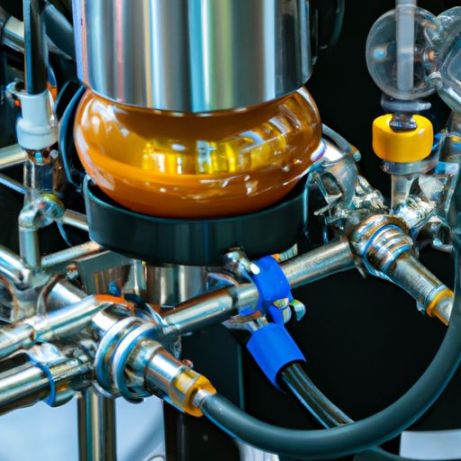

Extraction SCF Machine for Motor Oil Curcumin Extraction Equipment Supercritical CO2 Fluid

In the world of motor oil production, efficiency and quality are paramount. Manufacturers are constantly seeking ways to improve their processes and produce the best possible product for their customers. One technology that has revolutionized the industry is the extraction SCF machine, specifically designed for motor oil production. This equipment utilizes supercritical CO2 fluid to extract curcumin, a key component in motor oil, with unparalleled precision and efficiency.

One of the primary benefits of using an extraction SCF machine for motor oil production is the ability to extract curcumin at a higher purity level than traditional extraction methods. Supercritical CO2 fluid is able to penetrate the plant material more effectively, resulting in a purer extract with fewer impurities. This purity is crucial in motor oil production, as even small contaminants can affect the performance and longevity of the oil.

Additionally, the extraction SCF machine is able to extract curcumin more quickly than traditional methods. The supercritical CO2 fluid is able to dissolve the curcumin at a faster rate, reducing the overall extraction time and increasing production efficiency. This means that manufacturers can produce more motor oil in a shorter amount of time, ultimately increasing their output and profitability.

Another key benefit of using an extraction SCF machine for motor oil production is the ability to control the extraction process more precisely. The machine allows manufacturers to adjust the temperature and pressure of the supercritical CO2 fluid, resulting in a more customized extraction process. This level of control ensures that the curcumin is extracted in the most efficient and effective way possible, leading to a higher quality end product.

Another key benefit of using an extraction SCF machine for motor oil production is the ability to control the extraction process more precisely. The machine allows manufacturers to adjust the temperature and pressure of the supercritical CO2 fluid, resulting in a more customized extraction process. This level of control ensures that the curcumin is extracted in the most efficient and effective way possible, leading to a higher quality end product.

Furthermore, the extraction SCF machine is a more environmentally friendly option for motor oil production. Traditional extraction methods often use harsh Chemicals and solvents that can be harmful to the Environment. In contrast, supercritical CO2 fluid is a non-toxic and renewable solvent that can be easily recycled and reused. This reduces the overall environmental impact of the extraction process and aligns with the growing trend towards sustainable manufacturing practices.

In conclusion, the extraction SCF machine is a game-changer for motor oil production. Its ability to extract curcumin at a higher purity level, more quickly, and with greater precision makes it an invaluable tool for manufacturers looking to improve their processes and produce the best possible product. Additionally, its environmentally friendly nature aligns with the growing demand for sustainable manufacturing practices. Overall, the extraction SCF machine offers numerous benefits for motor oil production and is sure to continue revolutionizing the industry for years to come.

How Curcumin Extraction Equipment Utilizing Supercritical CO2 Fluid Works

Curcumin, a compound found in turmeric, has gained popularity in recent years for its potential health benefits. From its anti-inflammatory properties to its antioxidant effects, curcumin has been studied for its potential in treating a variety of health conditions. However, extracting curcumin from turmeric can be a complex process. This is where extraction SCF machines utilizing supercritical CO2 fluid come into play.

Supercritical fluid extraction is a process that uses supercritical fluids, such as carbon dioxide, to extract compounds from a solid or liquid material. In the case of curcumin extraction, supercritical CO2 fluid is used to extract the compound from turmeric. The process involves using high pressure and temperature to turn the CO2 into a supercritical state, where it behaves both like a gas and a liquid. This unique state allows the CO2 to effectively extract the curcumin from the turmeric, leaving behind a pure extract.

One of the key advantages of using supercritical CO2 fluid for curcumin extraction is its ability to produce a high-quality extract. Unlike traditional extraction methods that may use solvents or heat, supercritical CO2 extraction is a clean and efficient process that does not leave behind any residue or impurities. This results in a pure curcumin extract that is free from contaminants and retains its natural properties.

Another benefit of using extraction SCF machines for curcumin extraction is the ability to control the extraction process. By adjusting the pressure and temperature of the supercritical CO2 fluid, manufacturers can optimize the extraction process to yield the highest quality extract. This level of control allows for a more consistent and reliable extraction process, ensuring that each batch of curcumin extract meets the desired specifications.

Furthermore, supercritical CO2 extraction is a sustainable and environmentally friendly process. Unlike traditional extraction methods that may use harmful solvents or produce waste, supercritical CO2 extraction is a closed-loop system that recycles the CO2 used in the process. This not only reduces the environmental impact of the extraction process but also minimizes waste and energy consumption.

In addition to its efficiency and sustainability, extraction SCF machines utilizing supercritical CO2 fluid offer a cost-effective solution for curcumin extraction. While the initial investment in the equipment may be higher than traditional extraction methods, the long-term savings in terms of efficiency, quality, and sustainability make it a worthwhile investment for manufacturers looking to produce high-quality curcumin Extracts.

Overall, extraction SCF machines utilizing supercritical CO2 fluid offer a superior method for curcumin extraction. From its ability to produce high-quality extracts to its sustainability and cost-effectiveness, supercritical CO2 extraction is a preferred method for manufacturers looking to extract curcumin from turmeric. As the demand for curcumin continues to grow, extraction SCF machines will play a crucial role in meeting this demand while maintaining the quality and purity of the extract.