Table of Contents

Benefits of Using Electronic Controls and Power Modules Board in Industrial Applications

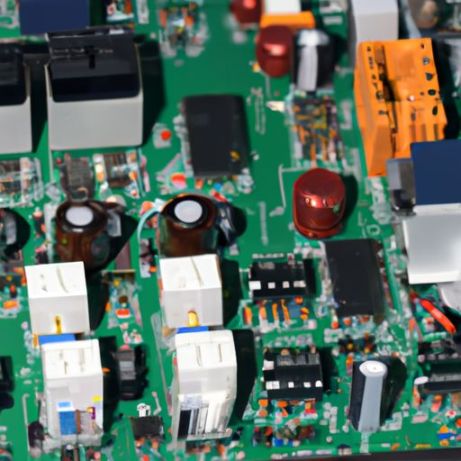

Electronic controls and power modules Boards are essential components in industrial applications where high temperatures are a concern. These boards are designed to withstand extreme heat and provide reliable performance in challenging environments. In this article, we will explore the benefits of using electronic controls and power modules boards in industrial settings, as well as the advantages of Ceramic PCB solutions for high-temperature applications.

One of the primary benefits of using electronic controls and power modules boards in industrial applications is their ability to operate efficiently at high temperatures. These boards are specifically designed to withstand heat and maintain their performance even in the most demanding conditions. This is crucial for industries such as automotive, aerospace, and oil and gas, where temperature fluctuations can be significant.

In addition to their high-temperature capabilities, electronic controls and power modules boards offer increased reliability and durability compared to traditional PCBs. These boards are built to last, with robust construction and high-quality materials that ensure long-term performance. This reliability is essential in industrial applications where downtime can be costly and disruptive to operations.

Furthermore, electronic controls and power modules boards provide enhanced functionality and flexibility for industrial systems. These boards can be customized to meet specific requirements, allowing for greater control and precision in industrial processes. Whether it’s monitoring temperature, regulating power output, or controlling machinery, electronic controls and power modules boards offer a versatile solution for a wide range of applications.

Another advantage of using electronic controls and power modules boards in industrial settings is their compact size and lightweight design. These boards can be easily integrated into existing systems without taking up valuable space or adding unnecessary weight. This is particularly important in industries where space is limited, such as automotive manufacturing or aerospace engineering.

Ceramic PCB solutions are another key component in high-temperature applications, offering additional benefits for industrial systems. Ceramic PCBs are known for their excellent thermal conductivity and heat dissipation properties, making them ideal for use in environments where temperature control is critical. These boards can withstand extreme heat without compromising performance, making them a reliable choice for industrial applications.

In addition to their thermal properties, ceramic PCB solutions offer high mechanical strength and resistance to corrosion, making them a durable and long-lasting option for industrial systems. These boards are designed to withstand harsh conditions and provide reliable performance in challenging environments. This durability is essential for industries where equipment is subjected to heavy use and wear.

Furthermore, ceramic PCB solutions offer excellent electrical insulation properties, reducing the risk of short circuits and electrical failures in industrial systems. This insulation is crucial for maintaining the integrity of electronic controls and power modules boards, ensuring consistent performance and reliability in high-temperature applications.

In conclusion, electronic controls and power modules boards, along with ceramic PCB solutions, offer numerous benefits for industrial applications where high temperatures are a concern. These components provide reliable performance, enhanced functionality, and durability in challenging environments, making them essential for industries such as automotive, aerospace, and oil and gas. By utilizing electronic controls and power modules boards and ceramic PCB solutions, industrial systems can operate efficiently and effectively in even the most extreme conditions.

In conclusion, electronic controls and power modules boards, along with ceramic PCB solutions, offer numerous benefits for industrial applications where high temperatures are a concern. These components provide reliable performance, enhanced functionality, and durability in challenging environments, making them essential for industries such as automotive, aerospace, and oil and gas. By utilizing electronic controls and power modules boards and ceramic PCB solutions, industrial systems can operate efficiently and effectively in even the most extreme conditions.

Advantages of Ceramic PCB Solutions for High Temperature Environments

In high temperature environments, electronic controls and power modules face unique challenges that can impact their performance and reliability. Traditional PCB materials, such as FR4, may not be able to withstand the extreme temperatures and thermal Cycling that are common in these environments. This is where ceramic PCB solutions come in, offering a range of advantages that make them ideal for high temperature applications.

One of the key advantages of ceramic PCB solutions is their ability to withstand high temperatures without compromising performance. Ceramic materials have a much higher thermal conductivity than traditional PCB materials, allowing them to dissipate heat more effectively and prevent overheating. This is crucial in high temperature environments where excessive heat can damage electronic components and Lead to system failure.

In addition to their superior thermal conductivity, ceramic PCB solutions also offer excellent mechanical strength and stability. This makes them highly resistant to thermal cycling, which is the repeated expansion and contraction of materials as they heat up and cool Down. In high temperature environments, thermal cycling can cause traditional PCB materials to warp or crack, leading to reliability issues and potential system failures. Ceramic PCB solutions, on the other hand, are able to withstand thermal cycling without any degradation in performance, ensuring the long-term reliability of electronic controls and power modules.

Another advantage of ceramic PCB solutions is their compatibility with high temperature soldering processes. Traditional PCB materials may not be able to withstand the high temperatures required for lead-free soldering, which can limit the manufacturing options available for high temperature applications. Ceramic PCB solutions, however, are able to withstand the temperatures required for lead-free soldering, making them a versatile and reliable choice for high temperature environments.

Furthermore, ceramic PCB solutions offer excellent chemical resistance, making them ideal for harsh environments where exposure to corrosive substances is a concern. Traditional PCB materials may be susceptible to corrosion over time, leading to performance degradation and potential system failures. Ceramic PCB solutions, on the other hand, are highly resistant to corrosion, ensuring the long-term reliability of electronic controls and power modules in high temperature environments.

Overall, ceramic PCB solutions offer a range of advantages that make them an ideal choice for high temperature applications. From their superior thermal conductivity and mechanical strength to their compatibility with high temperature soldering processes and excellent chemical resistance, ceramic PCB solutions provide the reliability and performance needed to withstand the unique challenges of high temperature environments. By choosing ceramic PCB solutions for electronic controls and power modules in high temperature applications, manufacturers can ensure the long-term reliability and performance of their systems.