Table of Contents

Benefits of Using Dry Type Transformers in Industrial Applications

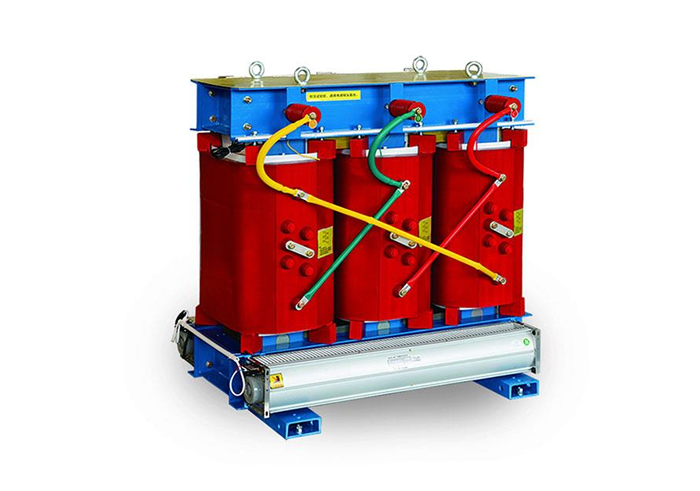

Transformers are essential components in electrical systems, as they help to regulate voltage Levels and ensure the safe and efficient distribution of electricity. There are two main types of transformers commonly used in industrial applications: dry type transformers and oil-filled transformers. In this article, we will explore the benefits of using dry type transformers in industrial settings.

Dry type transformers, as the name suggests, do not use oil as a cooling medium. Instead, they rely on air or other gases to dissipate heat generated during operation. This makes them a safer and more environmentally friendly option compared to oil-filled transformers, which can pose a risk of oil leaks and fires.

One of the key advantages of dry type transformers is their ability to operate in indoor environments without the need for special ventilation or fire suppression systems. This makes them ideal for use in buildings where space is limited or where strict Safety regulations are in place. Additionally, dry type transformers are more resistant to environmental contaminants such as dust, dirt, and moisture, which can degrade the performance of oil-filled transformers over time.

Another benefit of using dry type transformers is their lower maintenance requirements. Since they do not contain oil, there is no need for regular oil testing, filtering, or replacement. This can result in significant cost savings over the lifespan of the transformer. Additionally, dry type transformers have a longer service life compared to oil-filled transformers, as they are less susceptible to degradation from heat and moisture.

In terms of efficiency, dry type transformers are on par with oil-filled transformers, providing reliable voltage regulation and power distribution. They are also more energy-efficient, as they do not require energy to heat and circulate oil for cooling purposes. This can Lead to lower energy costs and reduced carbon emissions, making dry type transformers a more sustainable choice for industrial applications.

| Type | Rated\\u00a0capacity\\u00a0\\uff08KVA\\uff09 | Voltage\\u00a0combination\\uff08KV\\uff09 | Off-load\\u00a0losses\\uff08W\\uff09 | Load\\u00a0losses\\uff08W\\uff09 | Off-load\\u00a0current\\u00a0\\uff08%\\uff09 | Short-circuit\\u00a0impedance\\u00a0\\uff08%\\uff09 |

| SC12-30 | 30 | 6,6.3,6.6,10,11/0.4 | 150 | 710 | 2.0 | 4.0 |

| SC12-50 | 50 | 6,6.3,6.6,10,11/0.4 | 215 | 1000 | 2.0 | 4.0 |

| SC12-80 | 80 | 6,6.3,6.6,10,11/0.4 | 295 | 1380 | 1.5 | 4.0 |

| SC12-100 | 100 | 6,6.3,6.6,10,11/0.4 | 320 | 1570 | 1.5 | 4.0 |

| SC12-125 | 125 | 6,6.3,6.6,10,11/0.4 | 375 | 1850 | 1.3 | 4.0 |

| SCB12-160 | 160 | 6,6.3,6.6,10,11/0.4 | 430 | 2130 | 1.3 | 4.0 |

| SCB12-200 | 200 | 6,6.3,6.6,10,11/0.4 | 495 | 2530 | 1.1 | 4.0 |

| SCB12-250 | 250 | 6,6.3,6.6,10,11/0.4 | 575 | 2760 | 1.1 | 4.0 |

| SCB12-315 | 315 | 6,6.3,6.6,10,11/0.4 | 705 | 3470 | 1.0 | 4.0 |

| SCB12-400 | 400 | 6,6.3,6.6,10,11/0.4 | 785 | 3990 | 1.0 | 4.0 |

| SCB12-500 | 500 | 6,6.3,6.6,10,11/0.4 | 930 | 4880 | 1.0 | 4.0 |

| SCB12-630 | 630 | 6,6.3,6.6,10,11/0.4 | 1070 | 5880 | 0.85 | 4.0 |

| SCB12-630 | 630 | 6,6.3,6.6,10,11/0.4 | 1040 | 5960 | 0.85 | 6.0 |

| SCB12-800 | 800 | 6,6.3,6.6,10,11/0.4 | 1210 | 6960 | 0.85 | 6.0 |

| SCB12-1000 | 1000 | 6,6.3,6.6,10,11/0.4 | 1410 | 8130 | 0.85 | 6.0 |

| SCB12-1250 | 1250 | 6,6.3,6.6,10,11/0.4 | 1670 | 9690 | 0.85 | 6.0 |

| SCB12-1600 | 1600 | 6,6.3,6.6,10,11/0.4 | 1960 | 11700 | 0.85 | 6.0 |

| SCB12-2000 | 2000 | 6,6.3,6.6,10,11/0.4 | 2440 | 14400 | 0.7 | 6.0 |

| SCB12-2500 | 2500 | 6,6.3,6.6,10,11/0.4 | 2880 | 17100 | 0.7 | 6.0 |

When it comes to installation, dry type transformers offer greater flexibility and ease of use compared to oil-filled transformers. They can be mounted in any orientation and do not require a separate containment system for oil spills. This makes them easier to transport, handle, and install, saving time and labor costs during the setup process.

In conclusion, dry type transformers offer a range of benefits for industrial applications, including safety, environmental friendliness, low maintenance requirements, efficiency, and ease of installation. As a China exporter and maker of professional transformers, we are committed to providing high-quality products that meet the needs of our customers. To learn more about our dry type transformers and other products, please visit our website or watch our informative videos. Thank you for considering us as your trusted partner in electrical solutions.

How to Choose the Right Oil Filled Transformer for Your Power Distribution Needs

When it comes to power distribution, transformers play a crucial role in ensuring that electricity is efficiently transmitted from power plants to homes and businesses. There are various types of transformers available on the market, each with its own set of advantages and disadvantages. Two common types of transformers are dry type transformers and oil-filled transformers. In this article, we will discuss the differences between these two types of transformers and provide some tips on how to choose the right oil-filled transformer for your power distribution needs.

Dry type transformers, as the name suggests, do not use any liquid coolant for insulation. Instead, they rely on air to dissipate heat generated during operation. These transformers are typically used in indoor applications where fire safety is a concern, as they do not pose a risk of oil leakage or fire. Dry type transformers are also more environmentally friendly, as they do not contain any oil that could potentially leak and contaminate the surrounding Environment.

On the other hand, oil-filled transformers use oil as a coolant and insulating medium. The oil helps to dissipate heat more efficiently than air, allowing the transformer to operate at higher temperatures without overheating. Oil-filled transformers are commonly used in outdoor applications, such as pole-mounted transformers, where the risk of fire is lower and the transformer needs to withstand harsh weather conditions.

When choosing an oil-filled transformer for your power distribution needs, there are several factors to consider. First and foremost, you need to determine the power rating of the transformer, which is measured in kilovolt-amperes (kVA). The power rating of the transformer should be sufficient to handle the maximum load that will be connected to it, ensuring that it can deliver a steady supply of electricity without overheating or overloading.

Another important factor to consider is the voltage rating of the transformer. The voltage rating should match the voltage of the electrical system where the transformer will be installed, ensuring compatibility and safe operation. It is also important to consider the insulation class of the transformer, which indicates the maximum temperature that the insulation material can withstand. Choosing a transformer with a higher insulation class will ensure greater reliability and longevity.

In addition to these technical specifications, it is also important to consider the reputation and reliability of the transformer manufacturer. Look for a reputable and experienced transformer maker or exporter, such as those based in China, who have a proven track record of producing high-quality transformers that meet international standards. Professional transformer manufacturers will also provide technical support and assistance to help you choose the right transformer for your specific power distribution needs.

To learn more about oil-filled transformers and how to choose the right one for your power distribution needs, consider watching videos or tutorials provided by professional transformer makers and exporters. These videos can provide valuable insights into the different types of transformers available, their features and benefits, and how to select the best transformer for your specific application.

| Type | Rated\\u00a0capacity\\u00a0\\uff08KVA\\uff09 | Off-load\\u00a0losses\\uff08W\\uff09 | Voltage\\u00a0combination\\u00a0\\uff08KV\\uff09 | Load\\u00a0losses\\uff08W\\uff09 | Off-load\\u00a0current\\u00a0\\uff08%\\uff09 | Short-circuit\\u00a0voltage\\u00a0\\uff08%\\uff09 |

| S11-M-30 | 30 | 100 | 6,6.3,10,10.5,11/0.4 | 600 | 2.3 | 4.0 |

| S11-M-50 | 50 | 130 | 6,6.3,10,10.5,11/0.4 | 870 | 2.0 | 4.0 |

| S11-M-63 | 63 | 150 | 6,6.3,10,10.5,11/0.4 | 1040 | 1.9 | 4.0 |

| S11-M-80 | 80 | 180 | 6,6.3,10,10.5,11/0.4 | 1250 | 1.9 | 4.0 |

| S11-M-100 | 100 | 200 | 6,6.3,10,10.5,11/0.4 | 1500 | 1.8 | 4.0 |

| S11-M-125 | 125 | 240 | 6,6.3,10,10.5,11/0.4 | 1800 | 1.7 | 4.0 |

| S11-M-160 | 160 | 280 | 6,6.3,10,10.5,11/0.4 | 2200 | 1.6 | 4.0 |

| S11-M-200 | 200 | 340 | 6,6.3,10,10.5,11/0.4 | 2600 | 1.5 | 4.0 |

| S11-M-250 | 250 | 400 | 6,6.3,10,10.5,11/0.4 | 3050 | 1.4 | 4.0 |

| S11-M-315 | 315 | 480 | 6,6.3,10,10.5,11/0.4 | 3650 | 1.4 | 4.0 |

| S11-M-400 | 400 | 570 | 6,6.3,10,10.5,11/0.4 | 4300 | 1.3 | 4.0 |

| S11-M-500 | 500 | 680 | 6,6.3,10,10.5,11/0.4 | 5100 | 1.2 | 4.0 |

| S11-M-630 | 630 | 810 | 6,6.3,10,10.5,11/0.4 | 6200 | 1.1 | 4.5 |

| S11-M-800 | 800 | 980 | 6,6.3,10,10.5,11/0.4 | 7500 | 1.0 | 4.5 |

| S11-M-1000 | 1000 | 1150 | 6,6.3,10,10.5,11/0.4 | 10300 | 1.0 | 4.5 |

| S11-M-1250 | 1250 | 1360 | 6,6.3,10,10.5,11/0.4 | 12800 | 0.9 | 4.5 |

| S11-M-1600 | 1600 | 1640 | 6,6.3,10,10.5,11/0.4 | 14500 | 0.8 | 4.5 |

| S11-M-2000 | 2000 | 2280 | 6,6.3,10,10.5,11/0.4 | 17820 | 0.6 | 5.0 |

| S11-M-2500 | 2500 | 2700 | 6,6.3,10,10.5,11/0.4 | 20700 | 0.6 | 5.0 |

| S11-M-30- | 30 | 90 | 20,22/0.4 | 660 | 2.1 | 5.5 |

| S11-M-50- | 50 | 130 | 20,22/0.4 | 960 | 2 | 5.5 |

| S11-M-63- | 63 | 150 | 20,22/0.4 | 1145 | 1.9 | 5.5 |

| S11-M-80- | 80 | 180 | 20,22/0.4 | 1370 | 1.8 | 5.5 |

| S11-M-100- | 100 | 200 | 20,22/0.4 | 1650 | 1.6 | 5.5 |

| S11-M-125- | 125 | 240 | 20,22/0.4 | 1980 | 1.5 | 5.5 |

| S11-M-160- | 160 | 290 | 20,22/0.4 | 2420 | 1.4 | 5.5 |

| S11-M-200- | 200 | 330 | 20,22/0.4 | 2860 | 1.3 | 5.5 |

| S11-M-250- | 250 | 400 | 20,22/0.4 | 3350 | 1.2 | 5.5 |

| S11-M-315- | 315 | 480 | 20,22/0.4 | 4010 | 1.1 | 5.5 |

| S11-M-400- | 400 | 570 | 20,22/0.4 | 4730 | 1 | 5.5 |

| S11-M-500 | 500 | 680 | 20,22/0.4 | 5660 | 1 | 5.5 |

| S11-M-630 | 630 | 810 | 20,22/0.4 | 6820 | 0.9 | 6 |

| S11-M-800 | 800 | 980 | 20,22/0.4 | 8250 | 1.8 | 6 |

| S11-M-1000 | 1000 | 1150 | 20,22/0.4 | 11330 | 0.7 | 6 |

| S11-M-1250 | 1250 | 1350 | 20,22/0.4 | 13200 | 0.7 | 6 |

| S11-M-1600 | 1600 | 1630 | 20,22/0.4 | 15950 | 0.6 | 6 |

In conclusion, choosing the right oil-filled transformer for your power distribution needs requires careful consideration of technical specifications, voltage rating, insulation class, and the reputation of the transformer manufacturer. By following these tips and seeking guidance from professional transformer makers and exporters, you can ensure that you select a high-quality transformer that meets your power distribution requirements and provides reliable and efficient operation for years to come.