Table of Contents

Advantages of Dry Type Transformers for Industrial Applications

Transformers are an essential component in the electrical distribution system, responsible for stepping up or stepping Down voltage Levels to ensure efficient Power Transmission. When it comes to industrial applications, choosing the right type of transformer is crucial to ensure reliable and safe operation. Two common types of transformers used in industrial settings are dry type transformers and oil-filled transformers.

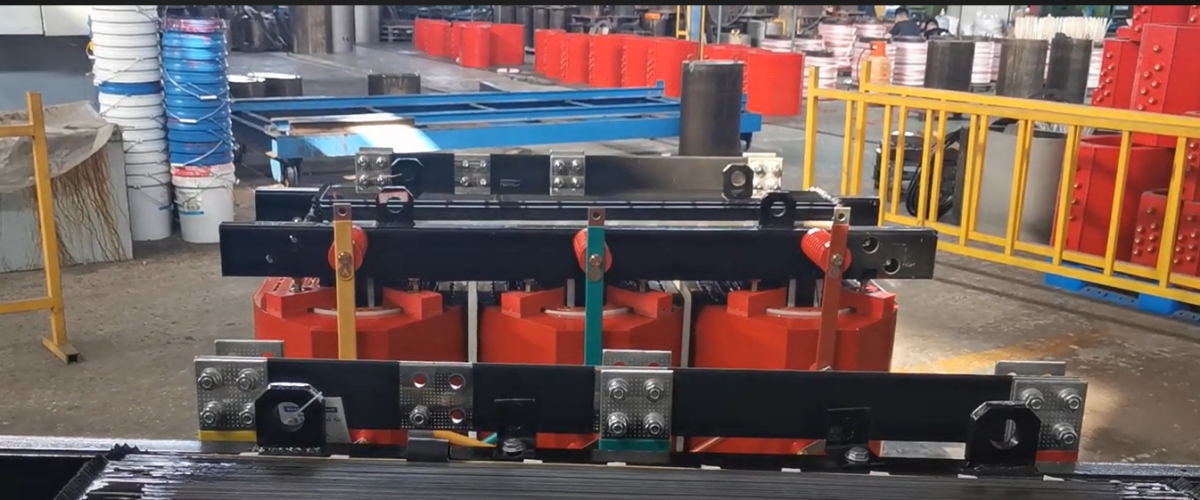

Dry type transformers, as the name suggests, do not use any liquid coolant for insulation. Instead, they rely on air or solid insulation materials to protect the windings from electrical faults. This design feature offers several advantages that make dry type transformers a popular choice for industrial applications.

One of the main advantages of dry type transformers is their environmental friendliness. Unlike oil-filled transformers, which require regular maintenance and pose a risk of oil leaks and spills, dry type transformers are maintenance-free and do not pose any environmental hazards. This makes them a preferred choice for industries that prioritize sustainability and environmental responsibility.

| model | Rating\\u00a0capacity\\u00a0\\uff08KVA\\uff09 | No-load\\u00a0losses\\uff08W\\uff09 | Voltage\\u00a0combination\\u00a0\\uff08KV\\uff09 | Load\\u00a0losses\\uff08W\\uff09 | No-load\\u00a0current\\u00a0\\uff08%\\uff09 | Short-circuit\\u00a0voltage\\u00a0\\uff08%\\uff09 |

| S11-M-30 | 30 | 100 | 6,6.3,10,10.5,11/0.4 | 600 | 2.3 | 4.0 |

| S11-M-50 | 50 | 130 | 6,6.3,10,10.5,11/0.4 | 870 | 2.0 | 4.0 |

| S11-M-63 | 63 | 150 | 6,6.3,10,10.5,11/0.4 | 1040 | 1.9 | 4.0 |

| S11-M-80 | 80 | 180 | 6,6.3,10,10.5,11/0.4 | 1250 | 1.9 | 4.0 |

| S11-M-100 | 100 | 200 | 6,6.3,10,10.5,11/0.4 | 1500 | 1.8 | 4.0 |

| S11-M-125 | 125 | 240 | 6,6.3,10,10.5,11/0.4 | 1800 | 1.7 | 4.0 |

| S11-M-160 | 160 | 280 | 6,6.3,10,10.5,11/0.4 | 2200 | 1.6 | 4.0 |

| S11-M-200 | 200 | 340 | 6,6.3,10,10.5,11/0.4 | 2600 | 1.5 | 4.0 |

| S11-M-250 | 250 | 400 | 6,6.3,10,10.5,11/0.4 | 3050 | 1.4 | 4.0 |

| S11-M-315 | 315 | 480 | 6,6.3,10,10.5,11/0.4 | 3650 | 1.4 | 4.0 |

| S11-M-400 | 400 | 570 | 6,6.3,10,10.5,11/0.4 | 4300 | 1.3 | 4.0 |

| S11-M-500 | 500 | 680 | 6,6.3,10,10.5,11/0.4 | 5100 | 1.2 | 4.0 |

| S11-M-630 | 630 | 810 | 6,6.3,10,10.5,11/0.4 | 6200 | 1.1 | 4.5 |

| S11-M-800 | 800 | 980 | 6,6.3,10,10.5,11/0.4 | 7500 | 1.0 | 4.5 |

| S11-M-1000 | 1000 | 1150 | 6,6.3,10,10.5,11/0.4 | 10300 | 1.0 | 4.5 |

| S11-M-1250 | 1250 | 1360 | 6,6.3,10,10.5,11/0.4 | 12800 | 0.9 | 4.5 |

| S11-M-1600 | 1600 | 1640 | 6,6.3,10,10.5,11/0.4 | 14500 | 0.8 | 4.5 |

| S11-M-2000 | 2000 | 2280 | 6,6.3,10,10.5,11/0.4 | 17820 | 0.6 | 5.0 |

| S11-M-2500 | 2500 | 2700 | 6,6.3,10,10.5,11/0.4 | 20700 | 0.6 | 5.0 |

| S11-M-30- | 30 | 90 | 20,22/0.4 | 660 | 2.1 | 5.5 |

| S11-M-50- | 50 | 130 | 20,22/0.4 | 960 | 2 | 5.5 |

| S11-M-63- | 63 | 150 | 20,22/0.4 | 1145 | 1.9 | 5.5 |

| S11-M-80- | 80 | 180 | 20,22/0.4 | 1370 | 1.8 | 5.5 |

| S11-M-100- | 100 | 200 | 20,22/0.4 | 1650 | 1.6 | 5.5 |

| S11-M-125- | 125 | 240 | 20,22/0.4 | 1980 | 1.5 | 5.5 |

| S11-M-160- | 160 | 290 | 20,22/0.4 | 2420 | 1.4 | 5.5 |

| S11-M-200- | 200 | 330 | 20,22/0.4 | 2860 | 1.3 | 5.5 |

| S11-M-250- | 250 | 400 | 20,22/0.4 | 3350 | 1.2 | 5.5 |

| S11-M-315- | 315 | 480 | 20,22/0.4 | 4010 | 1.1 | 5.5 |

| S11-M-400- | 400 | 570 | 20,22/0.4 | 4730 | 1 | 5.5 |

| S11-M-500 | 500 | 680 | 20,22/0.4 | 5660 | 1 | 5.5 |

| S11-M-630 | 630 | 810 | 20,22/0.4 | 6820 | 0.9 | 6 |

| S11-M-800 | 800 | 980 | 20,22/0.4 | 8250 | 1.8 | 6 |

| S11-M-1000 | 1000 | 1150 | 20,22/0.4 | 11330 | 0.7 | 6 |

| S11-M-1250 | 1250 | 1350 | 20,22/0.4 | 13200 | 0.7 | 6 |

| S11-M-1600 | 1600 | 1630 | 20,22/0.4 | 15950 | 0.6 | 6 |

In addition to being environmentally friendly, dry type transformers are also safer to operate. Since they do not contain any flammable liquids, the risk of fire is significantly reduced. This is especially important in industrial settings where Safety is a top priority. Furthermore, dry type transformers are more resistant to short circuits and overloads, making them a reliable and durable option for industrial applications.

Another advantage of dry type transformers is their compact size and lightweight design. This makes them easier to install and transport, saving time and labor costs. In addition, dry type transformers are suitable for indoor installation, as they do not require special ventilation or fire protection measures. This flexibility in installation options makes dry type transformers a versatile choice for a wide range of industrial applications.

Furthermore, dry type transformers are known for their high efficiency and low maintenance requirements. With no need for oil monitoring or replacement, dry type transformers offer a cost-effective solution for industrial facilities looking to minimize downtime and maintenance costs. Additionally, dry type transformers have a longer lifespan compared to oil-filled transformers, providing a reliable and long-lasting power distribution solution for industrial operations.

| model | Rating\\u00a0capacity\\u00a0\\uff08KVA\\uff09 | Voltage\\u00a0combination\\uff08KV\\uff09 | Off-load\\u00a0losses\\uff08W\\uff09 | Load\\u00a0losses\\uff08W\\uff09 | Off-load\\u00a0current\\u00a0\\uff08%\\uff09 | Short-circuit\\u00a0voltage\\u00a0\\uff08%\\uff09 |

| SC10-800 | 800 | 33,35,38/6,6.3,6.6,10,11 | 2200 | 9400 | 1.1 | 6.0 |

| SC10-1000 | 1000 | Voltage\\u00a0combination\\uff08KV\\uff09 | 2610 | 10800 | 1.1 | 6.0 |

| SC10-1250 | 1250 | 6,6.3,6.6,10,11/0.4 | 3060 | 11900 | 1.0 | 6.0 |

| SC10-1500 | 1500 | Voltage\\u00a0combination\\uff08KV\\uff09 | 3600 | 15400 | 1.0 | 6.0 |

| SC10-2000 | 2000 | 6,6.3,6.6,10,11/0.4 | 4130 | 18200 | 0.9 | 7.0 |

| SC10-2500 | 2500 | Voltage\\u00a0combination\\uff08KV\\uff09 | 4750 | 21800 | 0.9 | 7.0 |

| SC10-3150 | 3150 | 6,6.3,6.6,10,11/0.4 | 5880 | 24500 | 0.8 | 8.0 |

| SC10-4000 | 4000 | Voltage\\u00a0combination\\uff08KV\\uff09 | 6860 | 29400 | 0.8 | 8.0 |

| SC10-5000 | 5000 | 6,6.3,6.6,10,11/0.4 | 8180 | 34960 | 0.7 | 8.0 |

| SC10-6300 | 6300 | Voltage\\u00a0combination\\uff08KV\\uff09 | 9680 | 40800 | 0.7 | 8.0 |

| SC10-8000 | 8000 | 6,6.3,6.6,10,11/0.4 | 11000 | 46060 | 0.6 | 9.0 |

| SC10-10000 | 10000 | Voltage\\u00a0combination\\uff08KV\\uff09 | 12660 | 56500 | 0.6 | 9.0 |

| SC10-12500 | 12500 | 6,6.3,6.6,10,11/0.4 | 15400 | 64600 | 0.5 | 9.0 |

| SC10-16000 | 16000 | Voltage\\u00a0combination\\uff08KV\\uff09 | 18900 | 76000 | 0.5 | 9.0 |

| SC10-20000 | 20000 | 6,6.3,6.6,10,11/0.4 | 22400 | 85500 | 0.4 | 10.0 |

In conclusion, dry type transformers offer several advantages that make them a preferred choice for industrial applications. From their environmental friendliness and safety features to their compact size and high efficiency, dry type transformers provide a reliable and cost-effective solution for powering industrial equipment. Whether you are looking to upgrade your existing transformer system or install a new power distribution system, dry type transformers are a professional and reliable option to consider.

How to Choose the Right Oil Filled Transformer for Your Power Distribution Needs

When it comes to power distribution, choosing the right transformer is crucial. Transformers play a vital role in converting electrical energy from one voltage level to another, ensuring that electricity can be safely and efficiently distributed to homes, businesses, and industries. One of the key decisions you’ll need to make when selecting a transformer is whether to opt for a dry type or oil-filled transformer.

Dry type transformers are typically used in indoor applications where fire safety is a concern. These transformers are filled with a solid insulating material, such as epoxy resin, which eliminates the risk of oil leaks and fires. Dry type transformers are also more environmentally friendly than their oil-filled counterparts, as they do not require regular oil changes and maintenance.

On the other hand, oil-filled transformers are commonly used in outdoor applications where fire safety is less of a concern. These transformers are filled with mineral oil, which acts as a coolant and insulating material. Oil-filled transformers are generally more efficient than dry type transformers, as the oil helps to dissipate heat more effectively. However, they do require regular maintenance to ensure that the oil is clean and free of contaminants.

When choosing between a dry type and oil-filled transformer, it’s important to consider your specific application and requirements. If fire safety is a top priority, a dry type transformer may be the best option. However, if efficiency and performance are key considerations, an oil-filled transformer may be more suitable.

In addition to deciding between a dry type and oil-filled transformer, you’ll also need to consider whether a ground-mounted transformer is the right choice for your needs. Ground-mounted transformers are typically installed outdoors and are designed to withstand harsh weather conditions. These transformers are often used in industrial settings where space is not a constraint.

When selecting a ground-mounted transformer, it’s important to consider factors such as the size of the transformer, the voltage rating, and the load capacity. It’s also essential to ensure that the transformer is installed correctly and maintained regularly to prevent any issues or malfunctions.

If you’re in the market for a transformer, whether it be dry type, oil-filled, or ground-mounted, it’s essential to work with a reputable and experienced manufacturer. China has emerged as a leading exporter of transformers, with many companies offering high-quality products at competitive prices.

When choosing a transformer manufacturer in China, look for a company that has a proven track record of delivering reliable and efficient transformers. It’s also important to consider factors such as the company’s certifications, quality control processes, and customer reviews.

To learn more about choosing the right transformer for your power distribution needs, consider watching videos from professional transformer makers and exporters in China. These videos can provide valuable insights into the different types of transformers available, as well as tips for selecting the best transformer for your specific requirements.

In conclusion, selecting the right transformer for your power distribution needs is a critical decision that requires careful consideration. Whether you opt for a dry type or oil-filled transformer, or choose a ground-mounted transformer, it’s essential to work with a reputable manufacturer to ensure that you receive a high-quality product that meets your requirements. By doing your research and seeking advice from professionals, you can make an informed decision that will help you achieve reliable and efficient power distribution.