Table of Contents

The Benefits of Using Densen Customized Stainless Steel Polished Parts

Stainless steel is a versatile and durable material that is commonly used in a wide range of industries, from automotive to aerospace. Its strength, corrosion resistance, and aesthetic appeal make it a popular choice for many applications. When it comes to stainless steel parts, the finish is an important consideration. A polished finish not only enhances the appearance of the part but also provides additional benefits such as improved corrosion resistance and easier cleaning.

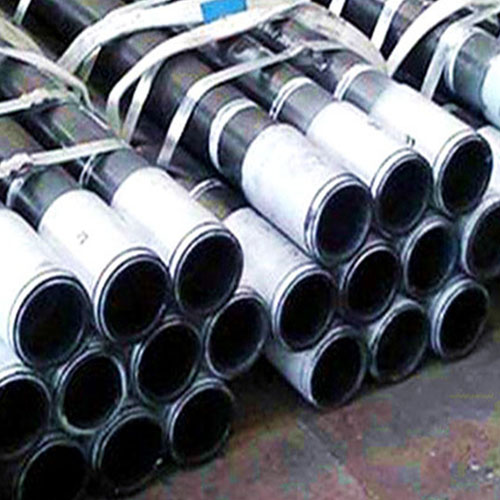

Densen is a leading provider of customized stainless steel polished parts, offering a wide range of services to meet the needs of their customers. One of the most popular services they offer is mirror polishing, which creates a highly reflective surface that is both visually appealing and functional. Mirror polishing is achieved through a series of abrasive processes that remove imperfections and create a smooth, shiny finish.

One of the key benefits of using Densen’s mirror polished stainless steel parts is the enhanced aesthetic appeal. The mirror-like finish creates a sleek and modern look that is perfect for high-end applications. Whether it’s a lighter casing, a medical device, or a piece of Furniture, mirror polished stainless steel parts add a touch of sophistication to any product.

In addition to its visual appeal, mirror polishing also offers practical benefits. The smooth surface created by the polishing process makes the stainless steel parts easier to clean and maintain. This is especially important in industries where cleanliness is a priority, such as food processing or medical equipment manufacturing. The reflective surface also helps to repel dirt and grime, keeping the parts looking new for longer.

Another benefit of using Densen’s mirror polished stainless steel parts is the improved corrosion resistance. The polishing process removes surface imperfections that can trap moisture and Lead to corrosion. By creating a smooth, uniform surface, mirror polishing helps to protect the stainless steel from environmental factors that can cause rust and degradation. This makes the parts more durable and long-lasting, saving time and money on maintenance and replacement costs.

Densen’s mirror polishing services are also highly customizable, allowing customers to achieve the exact finish they desire. Whether it’s a high-gloss shine or a satin finish, Densen can tailor their polishing process to meet the specific requirements of each project. This level of customization ensures that the finished parts not only look great but also perform optimally in their intended application.

In conclusion, the benefits of using Densen’s customized stainless steel polished parts are clear. From enhanced aesthetic appeal to improved corrosion resistance, mirror polishing offers a range of advantages that make it an ideal choice for a wide range of applications. Whether you’re looking to add a touch of elegance to your product or improve its performance and durability, Densen’s mirror polishing services can help you achieve your goals.