Table of Contents

Benefits of Road Fiber Factories in Improving Infrastructure

Road fiber factories play a crucial role in improving infrastructure by providing high-quality materials for road construction. These factories produce fiber-reinforced concrete, which is known for its durability and longevity. By incorporating fibers into concrete, roads become more resistant to cracking and deterioration, resulting in lower maintenance costs and longer service life.

One of the key benefits of road fiber factories is the ability to customize the fiber content to meet specific project requirements. Different types of fibers, such as steel, synthetic, or glass, can be used to enhance the performance of concrete in various ways. For example, steel fibers are commonly used to increase the tensile strength of concrete, while synthetic fibers can improve impact resistance. By tailoring the fiber content to the needs of a particular project, road fiber factories can ensure that roads are built to last.

In addition to enhancing the performance of concrete, fibers can also improve the workability of the material during construction. By reducing the amount of water and Cement needed in the mix, fibers can help to create a more cohesive and uniform concrete mixture. This not only makes the construction process more efficient but also results in a smoother and more durable road surface.

Furthermore, road fiber factories are able to produce materials that are environmentally friendly. By using recycled materials in the production of fibers, these factories can help to reduce waste and minimize the environmental impact of road construction. Additionally, the use of fiber-reinforced concrete can Lead to reduced energy consumption and lower greenhouse gas emissions over the life of the road.

Another advantage of road fiber factories is the ability to produce materials that are cost-effective. While the initial cost of fiber-reinforced concrete may be slightly higher than traditional concrete, the long-term savings in maintenance and repair costs can more than offset this initial investment. By building roads with materials that are more durable and resistant to wear and tear, municipalities can save money in the long run and ensure that their infrastructure remains in good condition for years to come.

| Serial Number | Item |

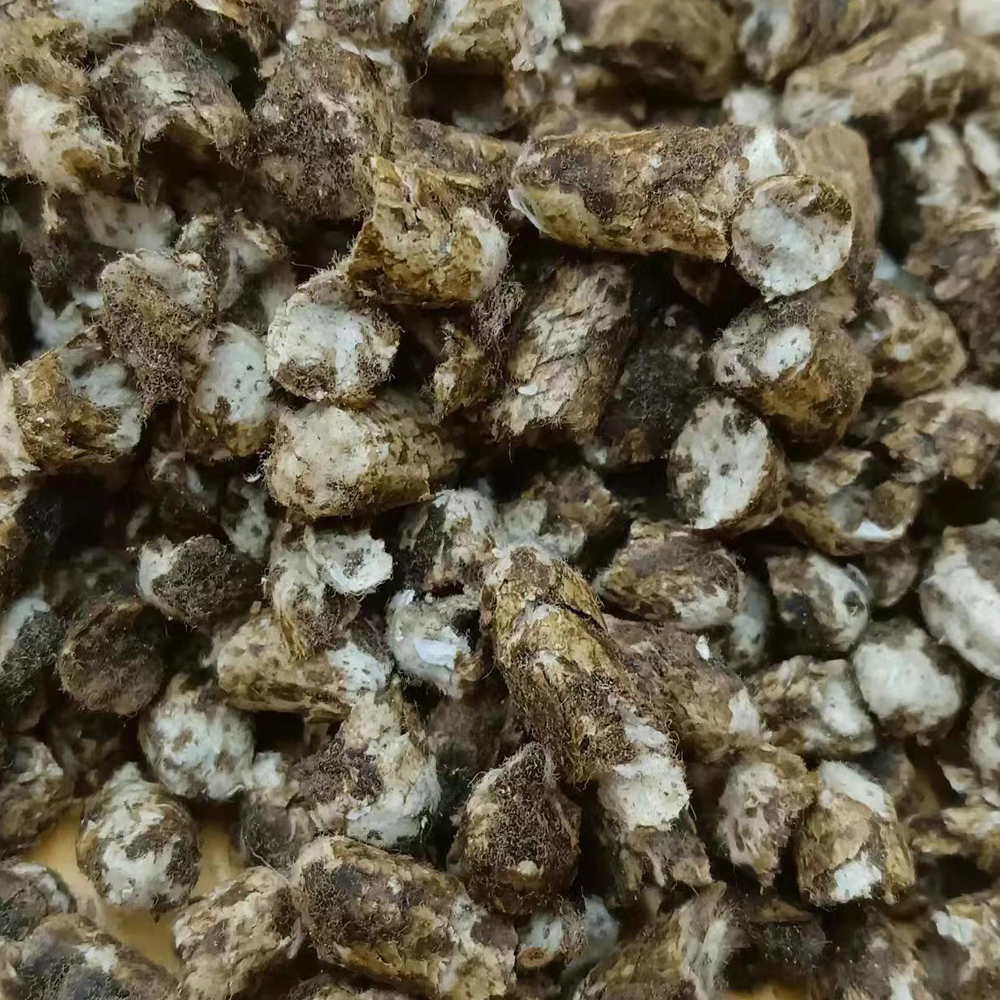

| 1 | Wood Pulp fibers used in asphalt |

Moreover, road fiber factories can help to improve the Safety of roads by reducing the risk of accidents and injuries. By providing a smoother and more uniform road surface, fiber-reinforced concrete can enhance the grip and traction of vehicles, especially in wet or icy conditions. This can help to prevent skidding and improve overall driving conditions, making roads safer for motorists and pedestrians alike.

In conclusion, road fiber factories play a vital role in improving infrastructure by providing high-quality materials for road construction. By customizing fiber content, enhancing concrete performance, improving workability, and reducing environmental impact, these factories can help to create roads that are more durable, cost-effective, and safe. With the growing demand for sustainable and resilient infrastructure, road fiber factories are poised to play an increasingly important role in shaping the future of road construction.

Sustainable Practices in Road Fiber Factories for Environmental Conservation

Road fiber factories play a crucial role in the construction and maintenance of roads, highways, and other infrastructure projects. These factories are responsible for producing the materials used to reinforce and strengthen asphalt and concrete, making them more durable and long-lasting. However, the production processes in road fiber factories can have a significant impact on the Environment if not managed properly. In recent years, there has been a growing emphasis on implementing sustainable practices in road fiber factories to minimize their environmental footprint and promote conservation efforts.

One of the key sustainable practices in road fiber factories is the use of recycled materials. By incorporating recycled materials such as old tires, Plastic Bottles, and other waste products into the production of road fibers, factories can reduce the amount of virgin materials needed and decrease the overall environmental impact of their operations. This not only helps to conserve natural resources but also reduces the amount of waste that ends up in landfills, contributing to a more circular economy.

In addition to using recycled materials, road fiber factories can also implement energy-efficient technologies to reduce their carbon footprint. By investing in energy-efficient equipment and processes, factories can lower their energy consumption and greenhouse gas emissions, leading to a more sustainable operation overall. This can include using Renewable Energy sources such as solar or wind power, as well as optimizing production processes to minimize energy waste.

Furthermore, road fiber factories can also focus on water conservation efforts to reduce their impact on local water resources. By implementing water Recycling and reuse systems, factories can minimize their water consumption and reduce the amount of wastewater generated during production. This not only helps to protect local water sources but also reduces the strain on municipal water treatment facilities, leading to a more sustainable operation overall.

Another important aspect of sustainable practices in road fiber factories is waste management. By implementing proper waste segregation and recycling programs, factories can minimize the amount of waste sent to landfills and promote a more sustainable approach to waste management. This can include recycling scrap materials, reusing packaging, and implementing composting programs to reduce organic waste. By taking a holistic approach to waste management, road fiber factories can significantly reduce their environmental impact and contribute to conservation efforts.

Overall, sustainable practices in road fiber factories are essential for promoting environmental conservation and reducing the industry’s impact on the planet. By incorporating recycled materials, implementing energy-efficient technologies, conserving water, and managing waste effectively, factories can minimize their environmental footprint and contribute to a more sustainable future. Through these efforts, road fiber factories can play a key role in promoting conservation and protecting the environment for future generations.