Table of Contents

Benefits of Using Cut Steel Wire in Various Applications

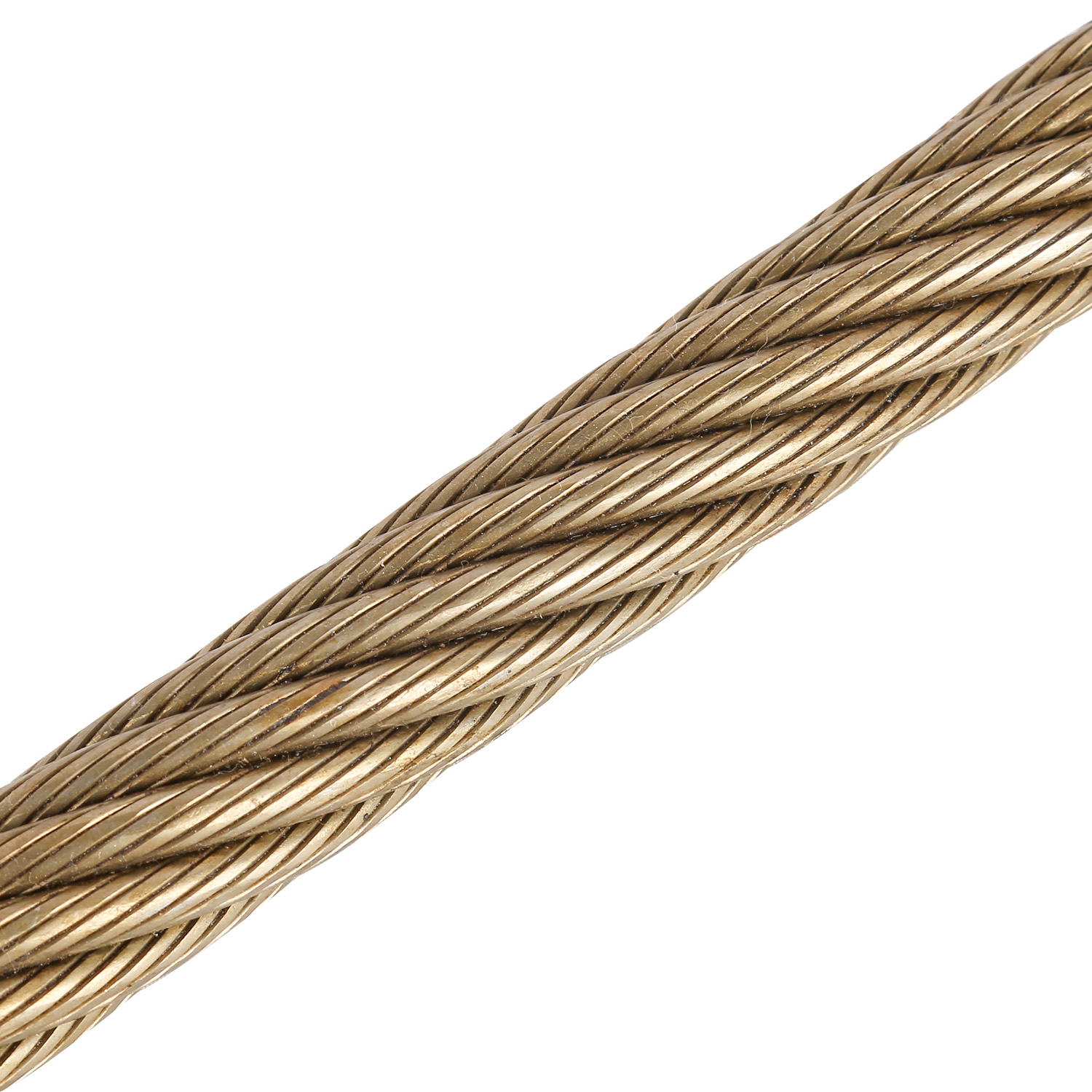

Steel wire is a versatile material that is used in a wide range of applications across various industries. One of the most common forms of steel wire is cut steel wire, which is widely used for its strength, durability, and flexibility. In this article, we will explore the benefits of using cut steel wire in various applications, including steel wire drill brushes and steel wire models.

Cut steel wire is a popular choice for many applications due to its high tensile strength and resistance to corrosion. This makes it an ideal material for use in construction, manufacturing, and other industries where durability and reliability are essential. Cut steel wire is also highly flexible, making it easy to work with and shape into different forms.

One common application of cut steel wire is in the production of steel wire drill brushes. These brushes are used for a variety of tasks, including cleaning, deburring, and polishing metal surfaces. The strong and durable nature of cut steel wire makes it an excellent choice for drill brushes, as it can withstand the rigors of heavy-duty use without breaking or bending.

Another popular application of cut steel wire is in the creation of steel wire models. These models are often used in engineering, architecture, and design to create detailed and accurate representations of structures, machines, and other objects. Cut steel wire is an ideal material for this purpose, as it can be easily manipulated and shaped to create intricate and precise models.

In addition to its strength and durability, cut steel wire is also highly cost-effective. Compared to other materials, such as Aluminum or Copper, steel wire is relatively inexpensive, making it a budget-friendly option for many applications. This affordability, combined with its long-lasting properties, makes cut steel wire a smart choice for businesses and individuals looking to save money without sacrificing quality.

Furthermore, cut steel wire is also environmentally friendly. Steel is a highly recyclable material, which means that cut steel wire can be easily recycled and reused, reducing waste and minimizing the environmental impact of production. By choosing cut steel wire for your applications, you can help contribute to a sustainable and eco-friendly practices.

Overall, the benefits of using cut steel wire in various applications are clear. Its strength, durability, flexibility, cost-effectiveness, and environmental friendliness make it a versatile and practical choice for a wide range of industries. Whether you are in construction, manufacturing, engineering, or design, cut steel wire is sure to meet your needs and exceed your expectations. Consider incorporating cut steel wire into your next project and experience the many advantages it has to offer.

How to Properly Use a Steel Wire Drill Brush for Cleaning

Steel wire drill brushes are a versatile tool that can be used for a variety of cleaning tasks. Whether you are removing rust, paint, or grime from metal surfaces, a steel wire drill brush can make the job much easier and more efficient. However, it is important to use this tool properly to avoid damaging the surface you are cleaning or injuring yourself. In this article, we will discuss how to properly use a steel wire drill brush for cleaning.

First and foremost, it is important to choose the right size and shape of steel wire drill brush for the task at hand. Steel wire drill brushes come in a variety of sizes and shapes, including cup brushes, wheel brushes, and end brushes. Cup brushes are ideal for cleaning large, flat surfaces, while wheel brushes are better suited for curved or irregular surfaces. End brushes are perfect for getting into tight spaces and corners. Make sure to select the appropriate brush for the job to ensure the best results.

Before using a steel wire drill brush, it is important to take proper Safety precautions. Wear safety goggles to protect your eyes from flying debris, and gloves to protect your hands from sharp wire bristles. It is also a good idea to wear a dust mask to prevent inhaling any particles that may be released during the cleaning process. Additionally, make sure to secure the workpiece properly to prevent it from moving or shifting while you are using the drill brush.

When using a steel wire drill brush, it is important to start at a low speed and gradually increase the speed as needed. Using a high speed right away can cause the wire bristles to fling off and potentially cause injury. Start by gently pressing the brush against the surface you are cleaning, and let the bristles do the work. Avoid applying too much pressure, as this can cause the bristles to wear out quickly and may damage the surface you are cleaning.

As you are using the steel wire drill brush, make sure to keep it moving at all times. Holding the brush in one spot for too long can cause heat buildup and potentially damage the surface you are cleaning. Move the brush back and forth, up and Down, and in circular motions to ensure even cleaning. If you are working on a large surface, it may be helpful to divide it into smaller sections and work on one section at a time.

After you have finished using the steel wire drill brush, make sure to clean it thoroughly to remove any debris or residue that may have accumulated on the bristles. Use a wire brush or compressed air to remove any buildup, and store the brush in a dry, clean place to prevent rusting. Proper maintenance of your steel wire drill brush will ensure that it lasts for a long time and continues to provide effective cleaning results.

In conclusion, steel wire drill brushes are a valuable tool for cleaning a variety of surfaces. By choosing the right brush for the job, taking proper safety precautions, and using the brush correctly, you can achieve excellent cleaning results without causing damage to the surface you are working on. Remember to start at a low speed, keep the brush moving, and clean it thoroughly after each use to ensure optimal performance. With proper care and attention, your steel wire drill brush will be a reliable tool for all your cleaning needs.

Step-by-Step Guide to Creating a Steel Wire Model for Hobbyists

Creating a steel wire model can be a rewarding and enjoyable hobby for those who have a passion for crafting and working with their hands. Whether you are a beginner or an experienced hobbyist, this step-by-step guide will help you create a beautiful steel wire model that you can proudly display in your home or give as a unique gift to a loved one.

To start, you will need a few essential tools and materials. The most important tool you will need is a pair of wire cutters. These will allow you to cut the steel wire to the desired lengths and shapes for your model. You will also need a steel wire drill brush, which will help you shape and manipulate the wire into intricate designs and patterns.

Once you have gathered your tools and materials, the first step is to sketch out your design on a piece of paper. This will serve as a guide for you as you begin to shape the steel wire. Start by cutting the wire into the lengths and shapes that you need for your model. Use the wire cutters to carefully trim the wire to the correct size, taking care to make clean and precise cuts.

Next, use the steel wire drill brush to shape the wire into the desired design. This tool is essential for creating intricate details and patterns in the wire. Gently guide the wire through the brush, twisting and turning it as needed to achieve the desired shape. Take your time and work slowly and carefully to ensure that the wire is shaped correctly.

As you work on shaping the wire, be sure to refer back to your sketch often to ensure that you are staying true to your design. Make any necessary adjustments as you go, taking care to maintain the overall shape and structure of the model. Remember that practice makes perfect, so don’t be afraid to experiment and try new techniques to achieve the desired look.

Once you have finished shaping the wire, you can add any additional details or embellishments to your model. This is where your creativity can really shine, so don’t be afraid to let your imagination run Wild. You can add beads, charms, or other decorative elements to enhance the overall look of your model.

Finally, once you are satisfied with the design of your steel wire model, you can secure the wire in place using a strong adhesive or soldering Iron. This will ensure that your model stays intact and can be displayed without fear of it falling apart.

In conclusion, creating a steel wire model is a fun and rewarding hobby that allows you to express your creativity and craftsmanship. By following this step-by-step guide, you can create a beautiful and unique model that you can proudly display in your home or give as a special gift to a loved one. So gather your tools and materials, sketch out your design, and start shaping your steel wire into a work of art today.