Table of Contents

Benefits of Using Warm Mix Additives in Asphalt Production

Asphalt is a commonly used material in road construction due to its durability and ability to withstand heavy traffic. However, traditional hot mix asphalt production can be energy-intensive and costly. In recent years, warm mix additives have gained popularity as a more sustainable and cost-effective alternative. These additives lower the production temperature of asphalt, resulting in numerous benefits for both producers and end-users.

| No. | Commodity Name |

| 1 | Asphalt modifier additives |

One of the primary benefits of using warm mix additives in asphalt production is reduced energy consumption. Traditional hot mix asphalt production requires high temperatures to heat the aggregate and binder, which can be energy-intensive. By lowering the production temperature with warm mix additives, producers can significantly reduce their energy consumption and greenhouse gas emissions. This not only helps to lower production costs but also contributes to a more sustainable and environmentally friendly production process.

| Part | Commodity Name |

| 1 | Liquid Anti-strip Agents |

In addition to energy savings, warm mix additives offer improved workability and compaction of asphalt mixtures. The lower production temperature allows for better coating and adhesion of the aggregate particles, resulting in a more uniform and durable pavement. This can Lead to longer-lasting roads with reduced maintenance and repair costs. Furthermore, the improved workability of warm mix asphalt can also result in faster construction times, reducing traffic disruptions and improving overall project efficiency.

| Serial Number | Product Name |

| 1 | Rutting Inhibitor Agent for Roadway |

Another benefit of using warm mix additives in asphalt production is enhanced pavement performance. The lower production temperature helps to preserve the properties of the binder, resulting in a more flexible and resilient pavement. This can improve resistance to cracking and rutting, leading to longer pavement life and reduced maintenance costs. Additionally, warm mix additives can improve the moisture resistance of asphalt mixtures, reducing the risk of moisture damage and extending the life of the pavement.

Furthermore, warm mix additives can also improve the sustainability of asphalt production by reducing emissions of harmful pollutants. The lower production temperature results in lower emissions of volatile organic compounds (VOCs) and other air pollutants, helping to improve air quality and reduce the environmental impact of asphalt production. This can be particularly beneficial in urban areas where air quality is a concern, as warm mix additives can help to mitigate the environmental impact of road construction projects.

| Part | Name |

| 1 | warm mix pavement enhancers |

| Number | Article Name |

| 1 | High Viscosity modifiers |

Overall, the benefits of using warm mix additives in asphalt production are numerous and significant. From energy savings and improved workability to enhanced pavement performance and reduced environmental impact, warm mix additives offer a more sustainable and cost-effective alternative to traditional hot mix asphalt production. By incorporating warm mix additives into their production processes, asphalt producers can improve the quality and durability of their pavements while also reducing their environmental footprint. As the demand for sustainable construction practices continues to grow, warm mix additives are poised to play a key role in the future of asphalt production.

| No. | Name |

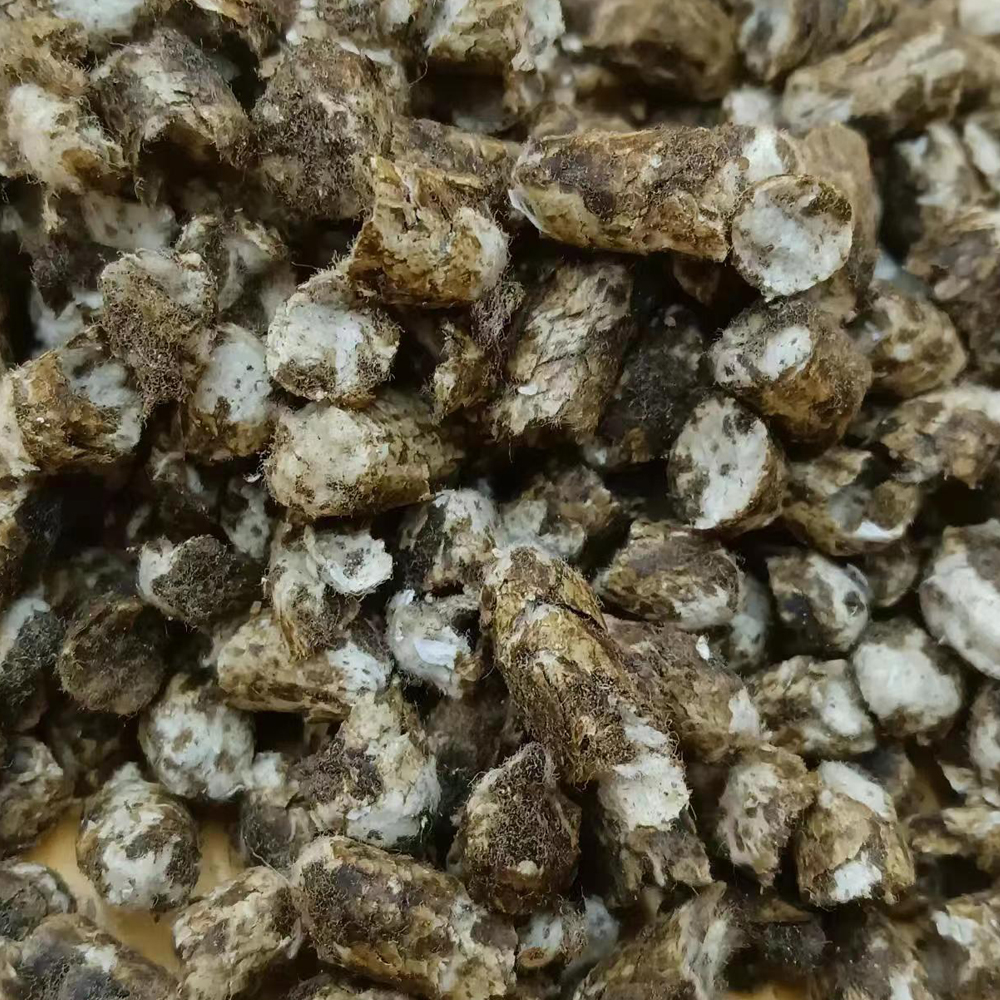

| 1 | Wood Cellulose Fibre |