Table of Contents

Benefits of Using UV Resistance Additives in Asphalt Pavement

Asphalt pavement is a popular choice for road construction due to its durability and cost-effectiveness. However, exposure to UV radiation can cause the asphalt to deteriorate over time, leading to cracks, potholes, and other forms of damage. To combat this issue, UV resistance additives are often used in the production of asphalt pavement.

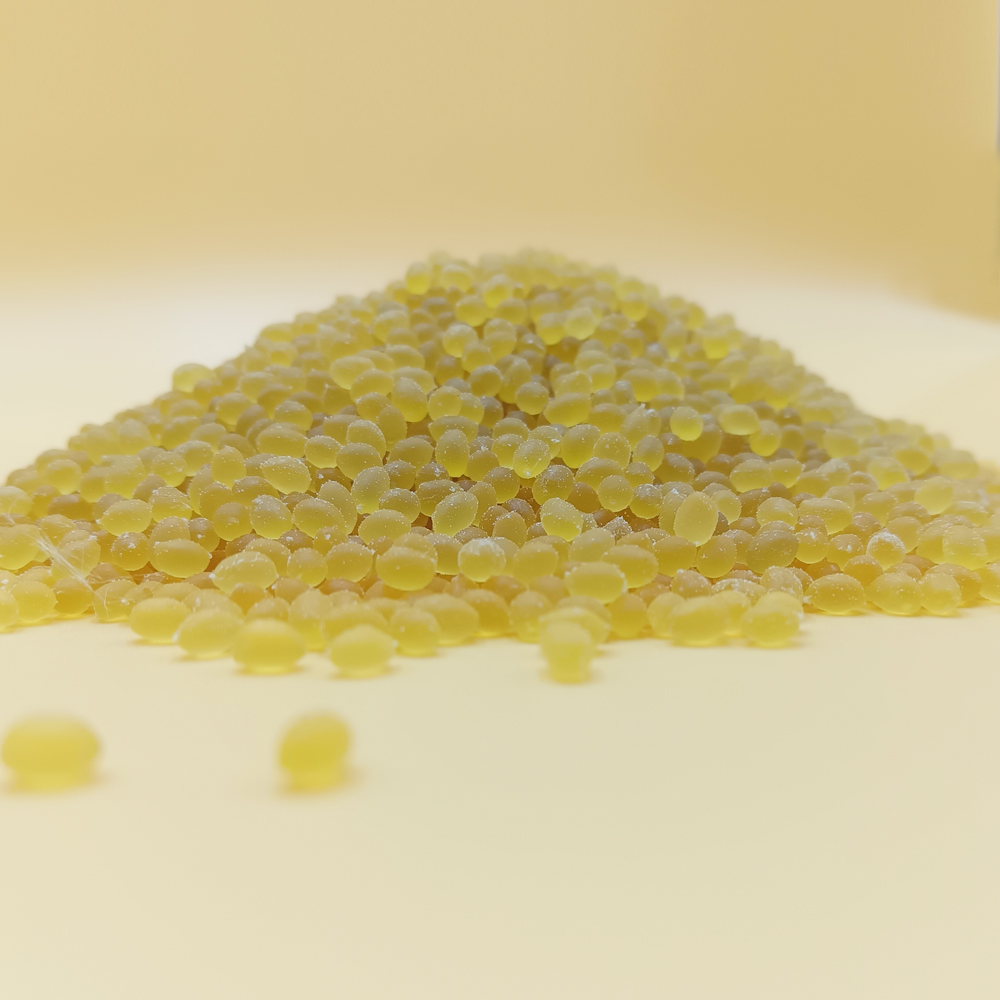

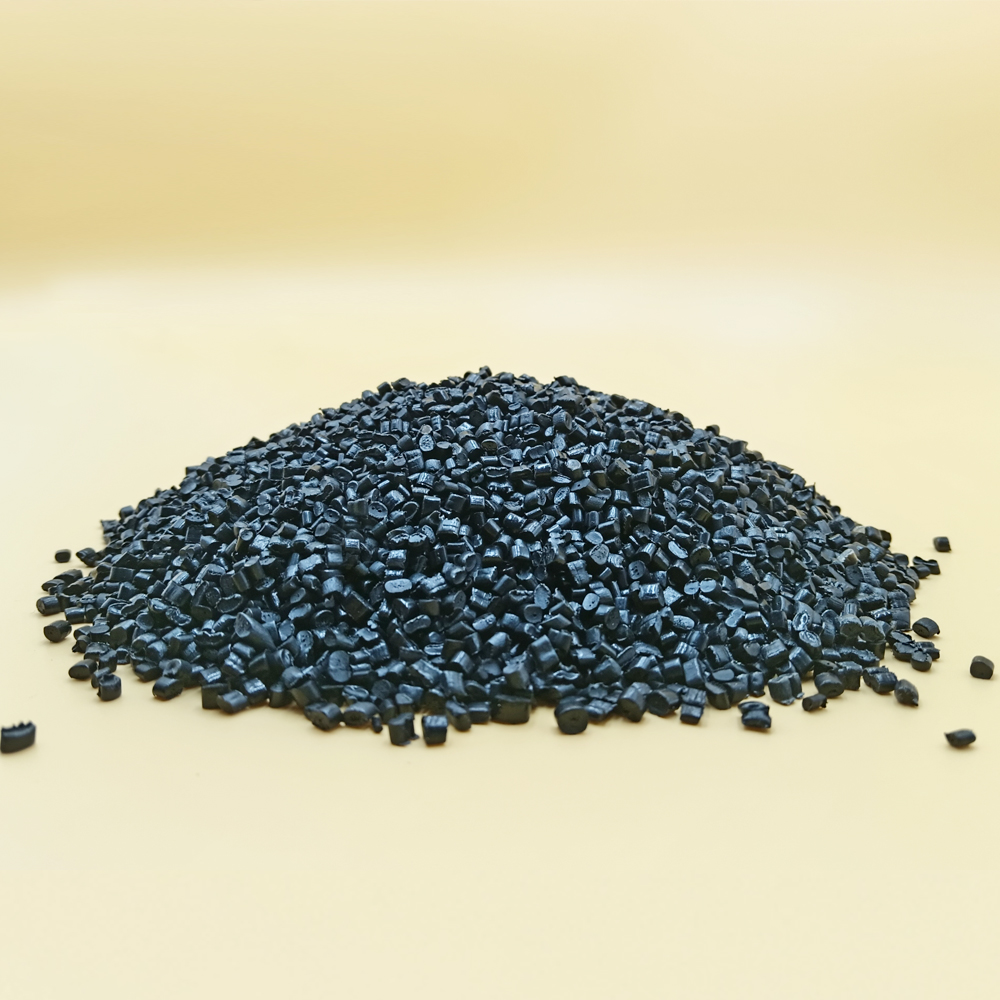

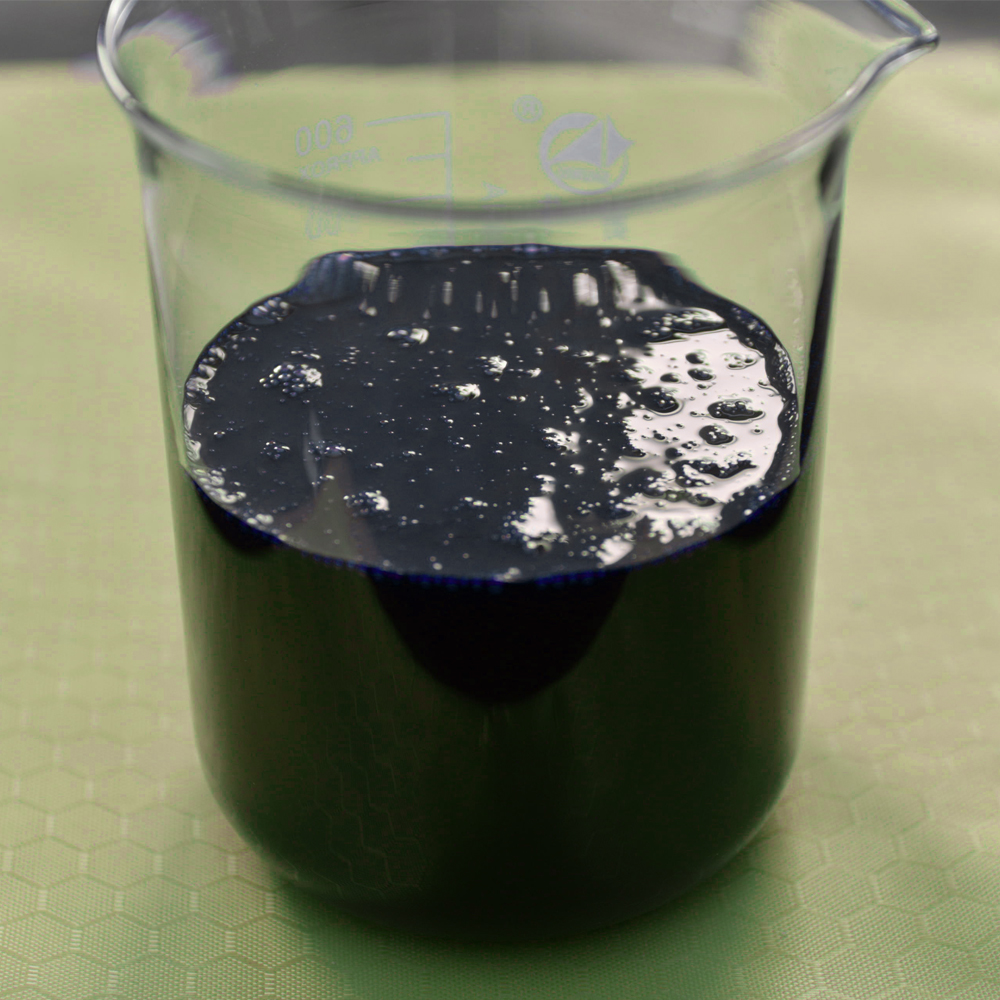

UV resistance additives are chemical compounds that are mixed into the asphalt mixture during production. These additives help to protect the asphalt from the harmful effects of UV radiation, prolonging the lifespan of the pavement and reducing the need for costly repairs and maintenance.

One of the key benefits of using UV resistance additives in asphalt pavement is increased durability. UV radiation can cause the asphalt to become brittle and prone to cracking, especially in hot climates. By incorporating UV resistance additives into the asphalt mixture, the pavement becomes more resistant to UV damage, resulting in a longer lifespan and reduced maintenance costs.

In addition to increased durability, UV resistance additives can also improve the overall performance of the asphalt pavement. These additives help to maintain the flexibility of the asphalt, preventing it from becoming stiff and prone to cracking. This flexibility allows the pavement to better withstand the stresses of heavy traffic and changing weather conditions, ensuring a smoother and safer driving surface for motorists.

| No. | Product |

| 1 | Warm Mix Asphalt (WMA) Additive |

Furthermore, UV resistance additives can also enhance the appearance of the asphalt pavement. UV radiation can cause the asphalt to fade and lose its color over time, giving it a worn and unattractive appearance. By using UV resistance additives, the asphalt retains its color and appearance for longer, improving the aesthetic appeal of the pavement and enhancing the overall look of the road.

| No. | Article Name |

| 1 | Viscosity enhancing modifiers |

Another benefit of using UV resistance additives in asphalt pavement is environmental protection. UV radiation can break Down the chemical bonds in the asphalt, releasing harmful pollutants into the Environment. By incorporating UV resistance additives into the asphalt mixture, the pavement becomes more resistant to UV damage, reducing the release of pollutants and helping to protect the environment.

| Nr. | Item |

| 1 | Liquid anti-stripping agent |

Overall, the use of UV resistance additives in asphalt pavement offers a wide range of benefits, including increased durability, improved performance, enhanced appearance, and environmental protection. By incorporating these additives into the production process, road builders can create asphalt pavements that are more resilient, longer-lasting, and better able to withstand the challenges of everyday use.

| No. | Article Name |

| 1 | rut resistance modifier for highway |

In conclusion, UV resistance additives play a crucial role in the production of asphalt pavement, helping to protect the pavement from the damaging effects of UV radiation. By using these additives, road builders can create asphalt pavements that are more durable, perform better, look better, and are more environmentally friendly. As the demand for high-quality, long-lasting roads continues to grow, the use of UV resistance additives in asphalt pavement will become increasingly important in ensuring the longevity and sustainability of our road infrastructure.

The Role of Production Additives in Enhancing Asphalt Quality

Asphalt pavement is a crucial component of our infrastructure, providing a durable and reliable surface for roads, parking lots, and other paved areas. However, over time, asphalt can deteriorate due to various factors, including exposure to ultraviolet (UV) radiation from the sun. UV radiation can cause the asphalt to become brittle and prone to cracking, reducing its lifespan and requiring costly repairs.

| Serial Number | Products |

| 1 | lignins fiber |

To combat the effects of UV radiation on asphalt pavement, production additives are often used during the manufacturing process. These additives are designed to enhance the UV resistance of the asphalt, improving its durability and longevity. By incorporating UV resistance additives into the asphalt mix, producers can create a more resilient pavement that can withstand the harsh effects of the sun.

| Serial Number | Name |

| 1 | for Road Security Industrial fiber |

| Part | Products |

| 1 | Asphalt friction modifiers |

One of the key benefits of using UV resistance additives in asphalt production is the ability to extend the lifespan of the pavement. By increasing the asphalt’s resistance to UV radiation, additives can help prevent premature deterioration and cracking, allowing the pavement to remain in good condition for longer periods. This can result in cost savings for municipalities and other entities responsible for maintaining roads and parking lots, as they can avoid the need for frequent repairs and resurfacing.

In addition to extending the lifespan of the pavement, UV resistance additives can also improve the overall quality of the asphalt. By enhancing the asphalt’s resistance to UV radiation, additives can help maintain the pavement’s flexibility and prevent it from becoming brittle over time. This can reduce the likelihood of cracking and other forms of damage, ensuring that the pavement remains smooth and safe for vehicles and pedestrians.

Furthermore, UV resistance additives can also enhance the appearance of the asphalt pavement. By protecting the asphalt from the damaging effects of UV radiation, additives can help maintain the pavement’s color and texture, preventing it from fading or becoming discolored over time. This can improve the aesthetic appeal of the pavement and enhance the overall appearance of the surrounding area.

Overall, the use of UV resistance additives in asphalt production plays a crucial role in enhancing the quality and longevity of asphalt pavement. By increasing the asphalt’s resistance to UV radiation, additives can help prevent premature deterioration, improve durability, and enhance the appearance of the pavement. This can result in cost savings for municipalities and other entities responsible for maintaining paved surfaces, as well as a safer and more attractive environment for drivers and pedestrians.

In conclusion, UV resistance additives are an essential component of asphalt production, helping to protect the pavement from the damaging effects of UV radiation. By incorporating these additives into the asphalt mix, producers can create a more durable and long-lasting pavement that can withstand the rigors of daily use. As our infrastructure continues to expand and evolve, the use of UV resistance additives will play an increasingly important role in ensuring the quality and longevity of our asphalt pavement.