Table of Contents

Benefits of Using Durability Additives in Asphalt Mixing

Asphalt is a commonly used material in road construction due to its durability and ability to withstand heavy traffic loads. However, over time, asphalt pavements can deteriorate due to factors such as weathering, traffic, and aging. To combat these issues and extend the lifespan of asphalt pavements, durability additives are often used in the asphalt mixing process.

Durability additives are materials that are added to asphalt mixtures to enhance their performance and longevity. These additives can improve the resistance of asphalt pavements to factors such as cracking, rutting, and moisture damage. By incorporating durability additives into the asphalt mixture, the overall quality and durability of the pavement can be significantly enhanced.

One of the key benefits of using durability additives in asphalt mixing is the improved resistance to cracking. Cracking is a common issue in asphalt pavements, especially in regions with extreme temperature fluctuations. Durability additives can help prevent cracking by improving the flexibility and elasticity of the asphalt mixture. This, in turn, helps to maintain the structural integrity of the pavement and reduce the need for costly repairs.

In addition to cracking resistance, durability additives can also improve the resistance of asphalt pavements to rutting. Rutting is a form of deformation that occurs in asphalt pavements due to repeated traffic loading. By incorporating durability additives into the asphalt mixture, the pavement can better withstand the stresses and strains caused by heavy traffic, resulting in a smoother and more durable surface.

Another benefit of using durability additives in asphalt mixing is the enhanced resistance to moisture damage. Moisture can seep into asphalt pavements through cracks and joints, leading to deterioration and reduced lifespan. Durability additives can help seal the asphalt mixture and prevent water infiltration, thereby protecting the pavement from moisture-related damage.

| Nr. | Product Name |

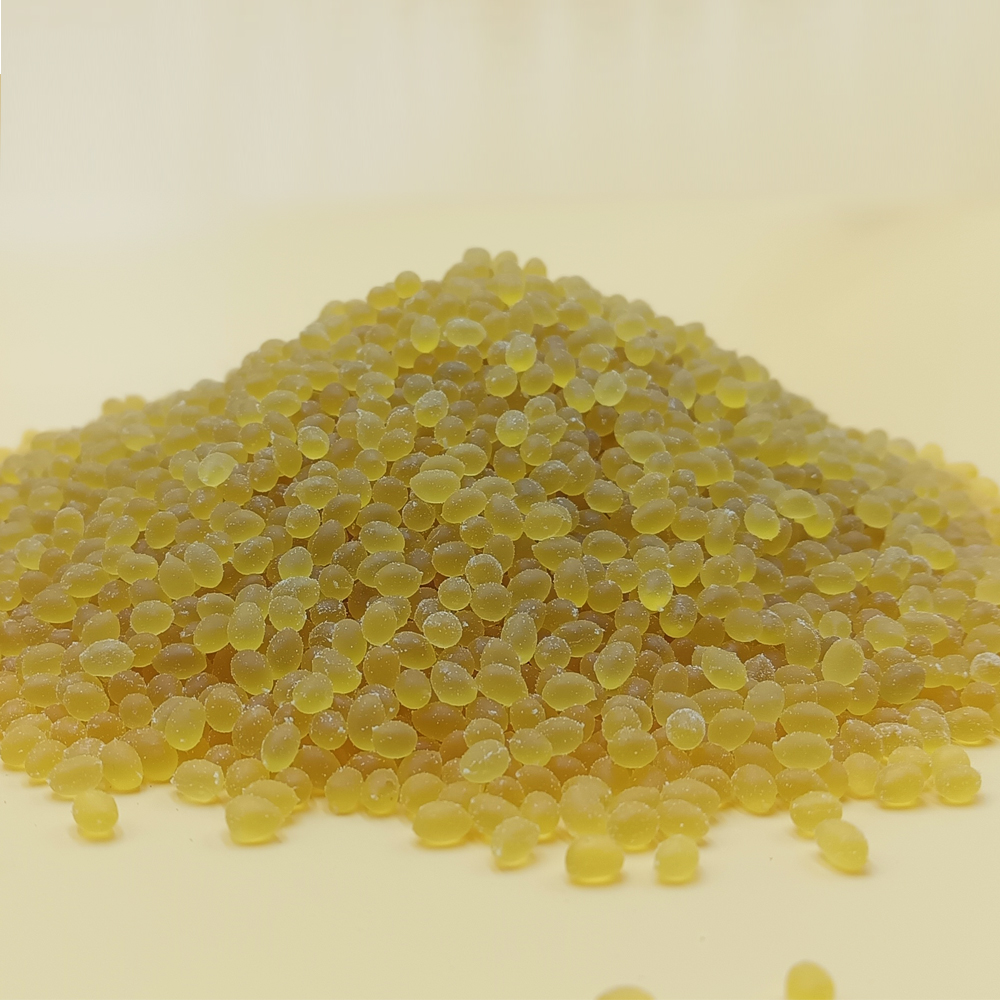

| 1 | Warm Mix Asphalt Component |

| Serial Number | Product |

| 1 | Bitumen pavement design additives |

Furthermore, durability additives can also improve the overall performance of asphalt pavements by enhancing their resistance to aging. As asphalt pavements age, they can become brittle and prone to cracking and deterioration. Durability additives can help slow Down the aging process by improving the durability and flexibility of the asphalt mixture, resulting in a longer-lasting pavement.

Overall, the use of durability additives in asphalt mixing offers a range of benefits that can help extend the lifespan of asphalt pavements and reduce maintenance costs. By improving the resistance of asphalt pavements to factors such as cracking, rutting, moisture damage, and aging, durability additives can enhance the overall quality and performance of asphalt pavements.

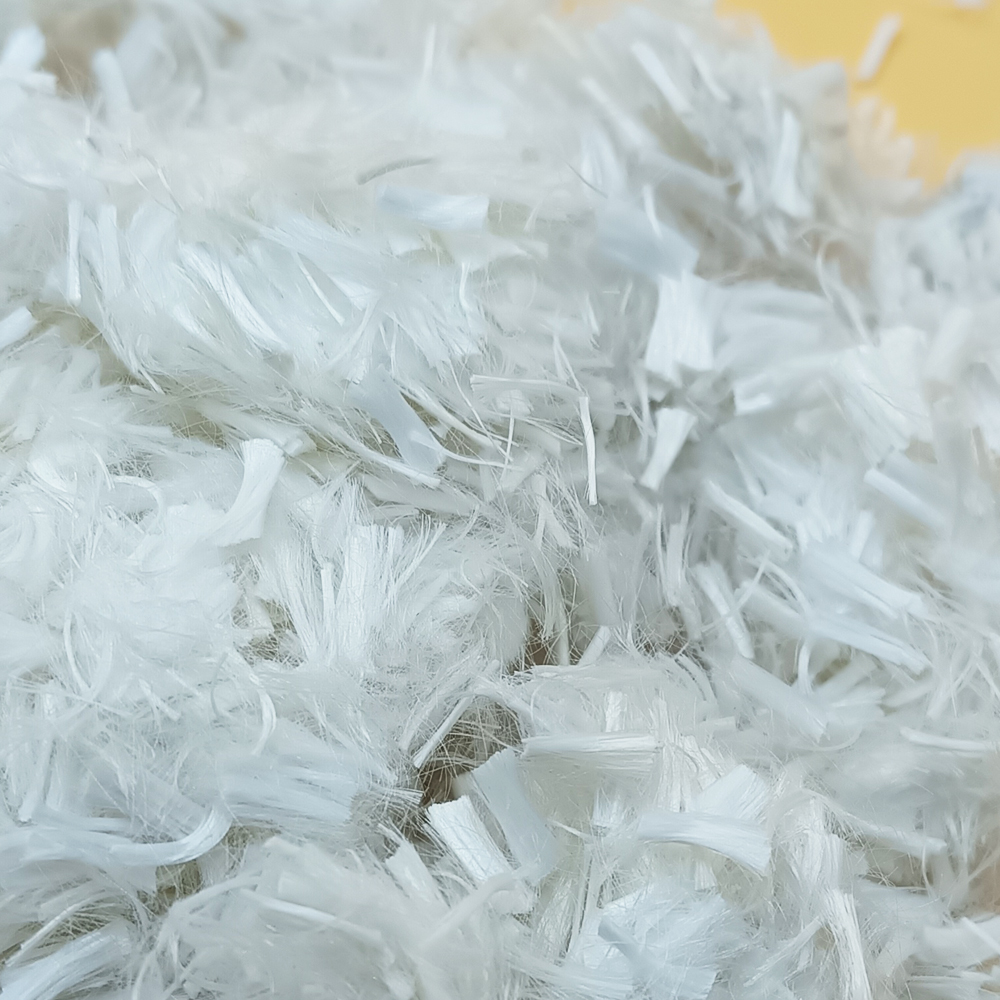

| Part | Article Name |

| 1 | for Road maintenance Polypropylene Fiber for road |

In conclusion, durability additives play a crucial role in enhancing the durability and longevity of asphalt pavements. By incorporating these additives into the asphalt mixture, road construction professionals can create pavements that are more resistant to cracking, rutting, moisture damage, and aging. Ultimately, the use of durability additives in asphalt mixing can help improve the overall quality and performance of asphalt pavements, leading to safer and more durable roadways for motorists and pedestrians alike.

Enhancing Pavement Performance with Value-Added Additives in Bitumen

Asphalt is a commonly used material in road construction due to its durability and ability to withstand heavy traffic loads. However, over time, asphalt pavements can deteriorate due to factors such as weathering, traffic, and aging. To enhance the performance and longevity of asphalt pavements, value-added additives are often incorporated into the bitumen during the mixing process.

| No. | Name |

| 1 | Wood Cellulose Fibre |

| No. | Commodity Name |

| 1 | for road Rutting Inhibitor modifier |

One of the key benefits of using value-added additives in asphalt mixing is the improvement in pavement durability. These additives can help increase the resistance of the asphalt pavement to factors such as rutting, cracking, and stripping. By enhancing the durability of the pavement, value-added additives can help extend the lifespan of the road, reducing the need for frequent repairs and maintenance.

In addition to improving pavement durability, value-added additives can also enhance the overall performance of the asphalt pavement. For example, additives such as polymers can help improve the flexibility and elasticity of the asphalt, making it more resistant to cracking and deformation. This can help reduce the occurrence of potholes and other pavement defects, leading to a smoother and safer driving surface for motorists.

Furthermore, value-added additives can also help improve the sustainability of asphalt pavements. By incorporating additives that increase the recycled content of the asphalt mix, such as reclaimed asphalt pavement (RAP) or recycled tire rubber, the environmental impact of road construction can be reduced. This not only helps conserve natural resources but also reduces the amount of waste that ends up in landfills.

| Part | Article Name |

| 1 | Basalt fiber composite reinforcement |

Another benefit of using value-added additives in asphalt mixing is the potential cost savings that can be achieved. While the initial cost of incorporating additives into the asphalt mix may be higher, the long-term benefits in terms of reduced maintenance and repair costs can outweigh this initial investment. By improving the durability and performance of the pavement, value-added additives can help minimize the need for costly repairs and prolong the lifespan of the road.

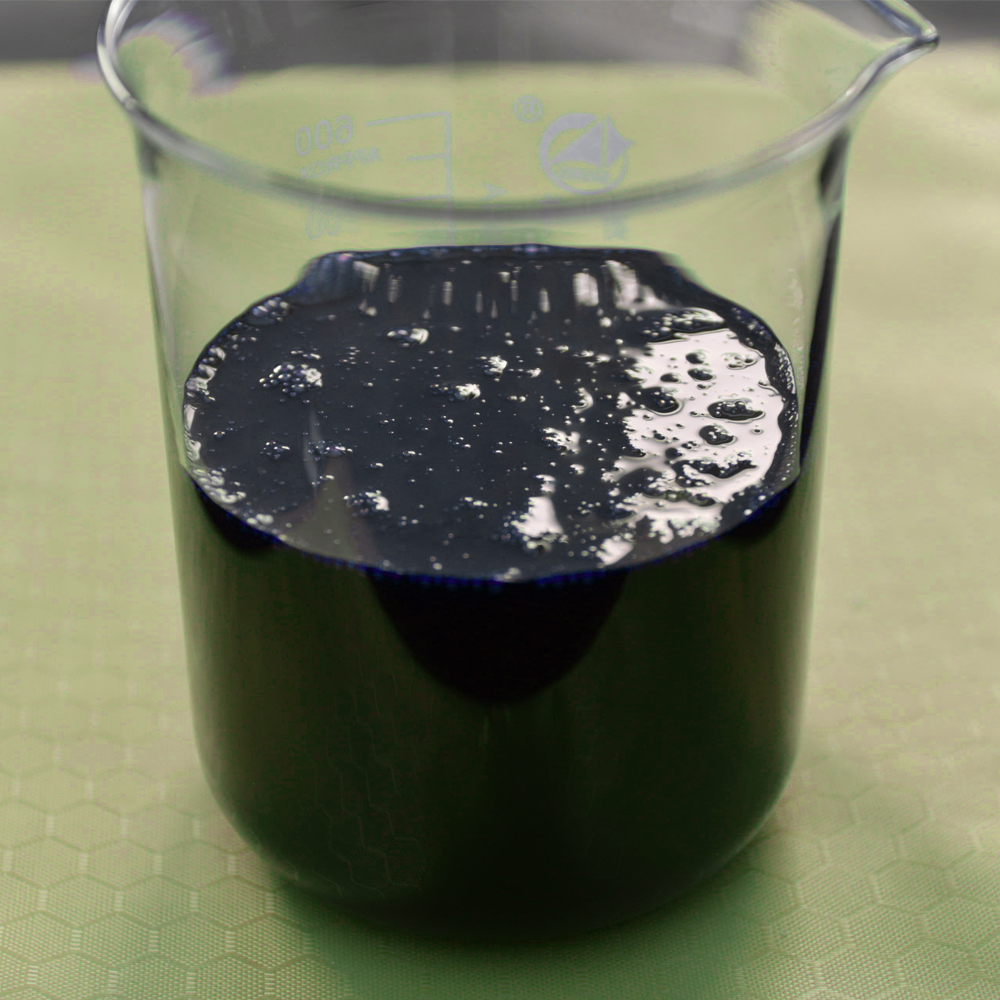

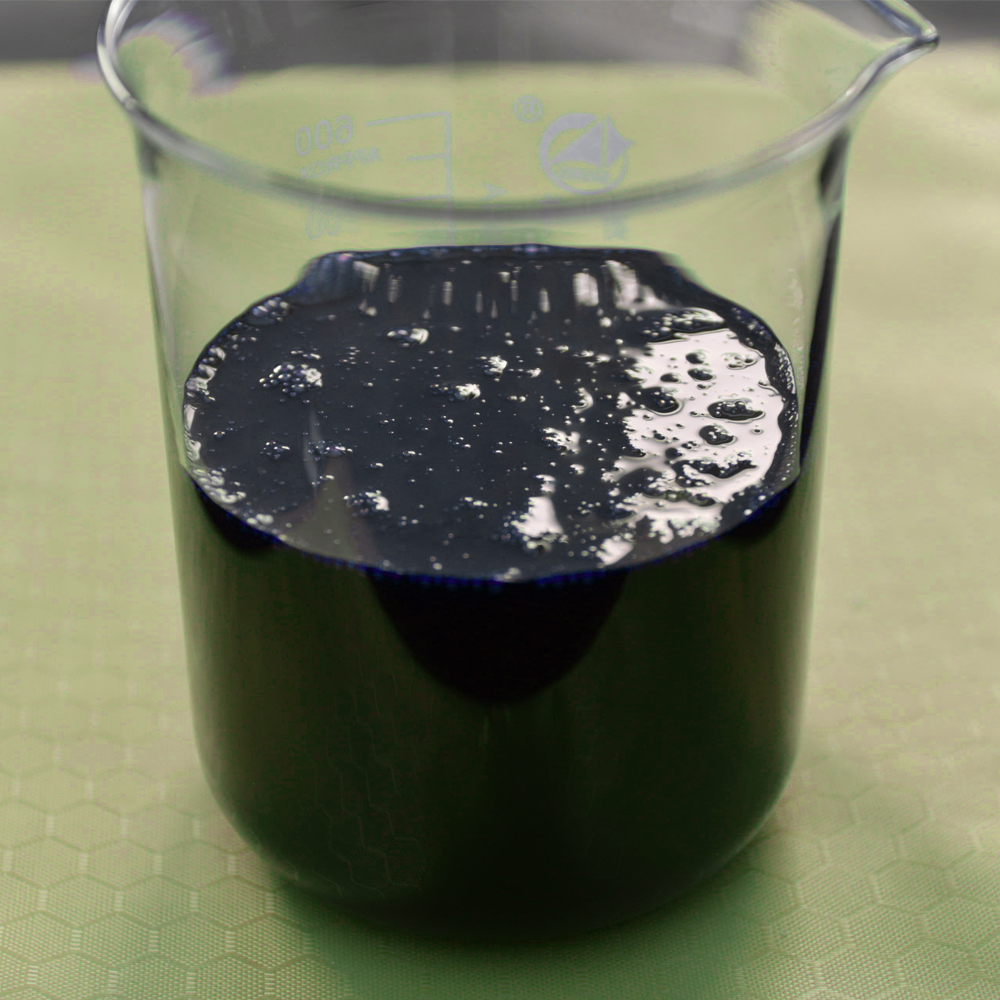

| Part | Product |

| 1 | Asphalt stripping resistance agent |

In conclusion, value-added additives play a crucial role in enhancing the performance and longevity of asphalt pavements. By improving pavement durability, enhancing performance, increasing sustainability, and potentially reducing costs, these additives offer a range of benefits for road construction projects. As the demand for more durable and sustainable road infrastructure continues to grow, the use of value-added additives in asphalt mixing is likely to become increasingly important in the years to come. By incorporating these additives into asphalt mixes, road authorities and contractors can ensure that their pavements are built to last and withstand the challenges of heavy traffic and harsh weather conditions.

| Part | Product Name |

| 1 | Viscosity enhancing Asphalt Binder |