Table of Contents

Benefits of Using Asphalt Anti-Stripping Additives

Asphalt anti-stripping additives, also known as asphalt bonding agents, are essential components in the construction and maintenance of asphalt pavements. These additives play a crucial role in enhancing the adhesion between asphalt binder and aggregate, thereby improving the overall performance and durability of the pavement. In this article, we will explore the benefits of using asphalt anti-stripping additives and why they are a valuable investment for any asphalt project.

One of the primary benefits of using asphalt anti-stripping additives is their ability to prevent moisture damage. Moisture is one of the leading causes of pavement distress, as it can weaken the bond between the asphalt binder and aggregate, leading to stripping and rutting. By incorporating anti-stripping additives into the asphalt mix, the adhesion between the binder and aggregate is significantly improved, reducing the risk of moisture damage and extending the lifespan of the pavement.

In addition to preventing moisture damage, asphalt anti-stripping additives also enhance the overall performance of the pavement. These additives improve the cohesion and adhesion properties of the asphalt mix, resulting in a more durable and resilient pavement that can withstand heavy traffic loads and harsh weather conditions. This, in turn, reduces the need for frequent repairs and maintenance, saving time and money in the long run.

Furthermore, asphalt anti-stripping additives can improve the workability of the asphalt mix, making it easier to handle and compact during construction. This can Lead to a smoother and more uniform pavement surface, reducing the risk of surface defects and improving the overall aesthetics of the pavement. Additionally, the improved workability of the asphalt mix can help contractors achieve better compaction and density, resulting in a stronger and more durable pavement.

Another benefit of using asphalt anti-stripping additives is their environmental impact. By improving the performance and durability of the pavement, these additives can help reduce the need for frequent resurfacing and reconstruction, which can generate significant amounts of waste and consume valuable resources. By extending the lifespan of the pavement, anti-stripping additives can help reduce the overall environmental footprint of asphalt projects and contribute to sustainable construction practices.

| Part | Product Name |

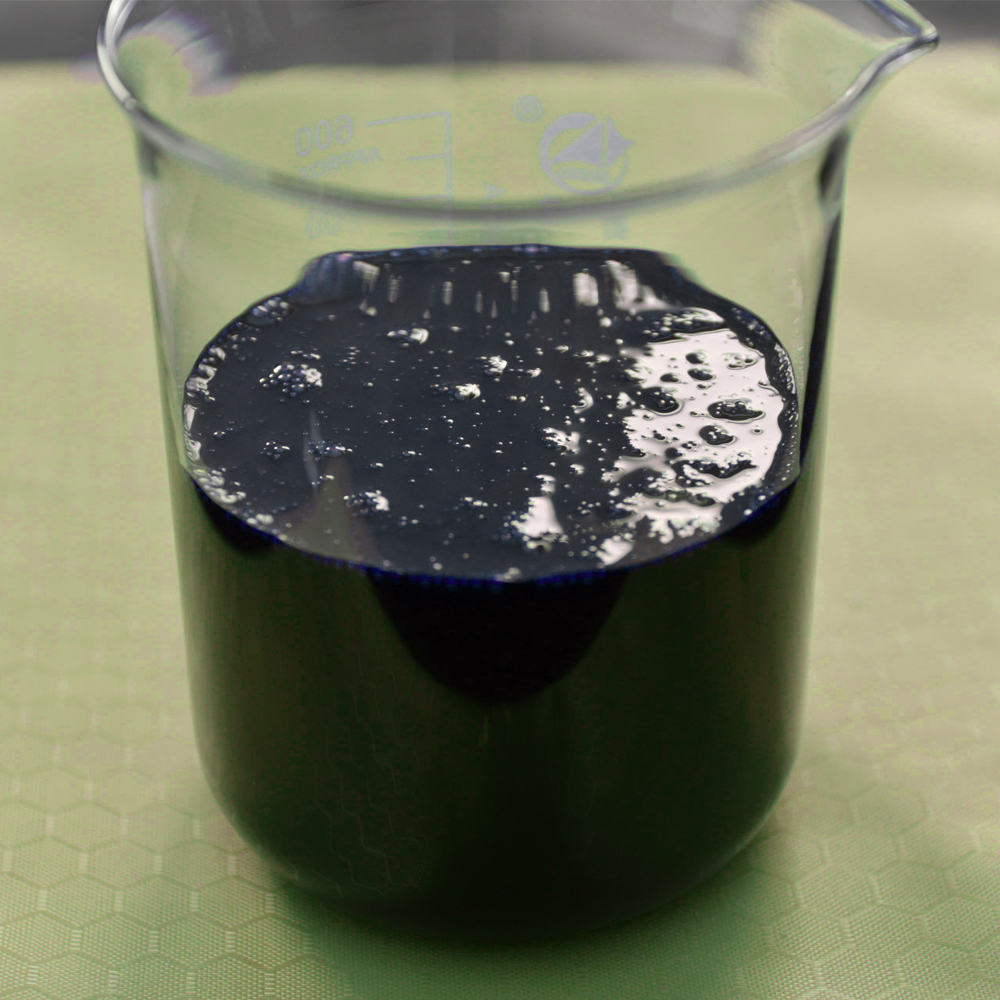

| 1 | Stripping resistance agent |

Overall, the benefits of using asphalt anti-stripping additives are clear. These additives can prevent moisture damage, enhance pavement performance, improve workability, and reduce environmental impact, making them a valuable investment for any asphalt project. Whether you are constructing a new pavement or maintaining an existing one, incorporating asphalt anti-stripping additives into your asphalt mix can help ensure a durable, long-lasting, and sustainable pavement that will stand the test of time.

How to Choose the Right Asphalt Bonding Agent Additive

Asphalt bonding agent additives, also known as anti-stripping additives, are crucial components in asphalt mixtures that help improve the bond between asphalt and aggregates. This is essential for ensuring the durability and longevity of asphalt pavements. With so many options available on the market, choosing the right asphalt bonding agent additive can be a daunting task. In this article, we will discuss some key factors to consider when selecting the right additive for your asphalt mixture.

One of the most important factors to consider when choosing an asphalt bonding agent additive is the type of aggregate being used in the asphalt mixture. Different aggregates have different surface characteristics, which can affect the bond between the asphalt and the aggregate. For example, aggregates with high moisture content or certain types of surface coatings may require a different type of bonding agent additive compared to aggregates with a more porous surface. It is important to consider the specific properties of the aggregates being used in order to select an additive that will provide the best bond.

Another important factor to consider when choosing an asphalt bonding agent additive is the climate and environmental conditions in which the asphalt pavement will be placed. Different additives have different resistance to moisture and temperature fluctuations, so it is important to select an additive that is suitable for the specific climate and environmental conditions of the project site. For example, in areas with high Levels of rainfall, it may be necessary to use an additive that provides enhanced moisture resistance to prevent stripping and premature pavement failure.

In addition to considering the type of aggregate and environmental conditions, it is also important to consider the compatibility of the asphalt bonding agent additive with the asphalt binder being used in the mixture. Some additives may not be compatible with certain types of asphalt binders, which can lead to issues such as reduced bond strength or premature aging of the pavement. It is important to consult with the manufacturer of the asphalt binder to ensure that the additive being used is compatible with the binder.

When selecting an asphalt bonding agent additive, it is also important to consider the application rate and mixing procedures recommended by the manufacturer. Using the correct application rate and following the recommended mixing procedures are essential for achieving the desired bond strength and performance of the asphalt pavement. It is important to carefully follow the manufacturer’s instructions to ensure that the additive is properly dispersed throughout the asphalt mixture.

In conclusion, choosing the right asphalt bonding agent additive is crucial for ensuring the durability and longevity of asphalt pavements. By considering factors such as the type of aggregate, environmental conditions, compatibility with asphalt binders, and application rate, you can select an additive that will provide the best bond between the asphalt and aggregates. Consulting with the manufacturer of the asphalt binder and following their recommendations for application and mixing procedures will help ensure the success of your asphalt pavement project.