Table of Contents

الفولاذ المستخدم في بناء البرجين التوأمين

فهم قطر أسلاك الفولاذ ذات قياس 9

يبلغ قطر السلك الفولاذي ذو قياس 9 حوالي 0.1144 بوصة، أو 2.906 ملم. يعتبر هذا السُمك مثاليًا للتطبيقات التي تتطلب قوة ومتانة عالية، كما هو الحال في تشييد المباني الشاهقة مثل البرجين التوأمين. لعب استخدام الأسلاك الفولاذية مقاس 9 في بناء البرجين التوأمين دورًا حاسمًا في قدرتهم على تحمل القوى الموضوعة عليهم.

بالإضافة إلى قوتها ومتانتها، من السهل نسبيًا العمل مع الأسلاك الفولاذية مقاس 9. . وهذا يجعله خيارًا شائعًا لمشاريع البناء حيث الدقة والدقة مهمة. سمح استخدام الأسلاك الفولاذية ذات القياس 9 في بناء البرجين التوأمين بإنشاء تصميمات هيكلية معقدة ومعقدة ساعدت في جعل المباني بارزة في أفق مدينة نيويورك.

بشكل عام، الفولاذ المستخدم في بناء لعب البرجان التوأم، بما في ذلك الأسلاك الفولاذية ذات قياس 9، دورًا حاسمًا في السلامة الهيكلية للمباني والتصميم العام. ساعد استخدام الفولاذ عالي القوة ومنخفض السبائك مثل ASTM A36، جنبًا إلى جنب مع سمك سلك فولاذي قياس 9، على ضمان قدرة البرجين التوأمين على تحمل الوزن الهائل والضغط الواقع عليهما. إن قطر الأسلاك الفولاذية ذات قياس 9 هو مجرد مثال واحد على العديد من العوامل التي تدخل في تشييد المباني الشاهقة وغيرها من الهياكل.

The Twin Towers, also known as the World Trade Center in New York City, were iconic symbols of the city’s skyline before the tragic events of September 11, 2001. These towers were constructed using a variety of materials, including steel. The steel used in the construction of the Twin Towers was a crucial component in their structural integrity and overall design.

The steel used in the construction of the Twin Towers was a high-strength, low-Alloy Steel known as ASTM A36. This type of steel is commonly used in construction due to its strength and durability. The steel used in the Twin Towers was specifically chosen for its ability to withstand the immense weight and stress placed on the buildings.

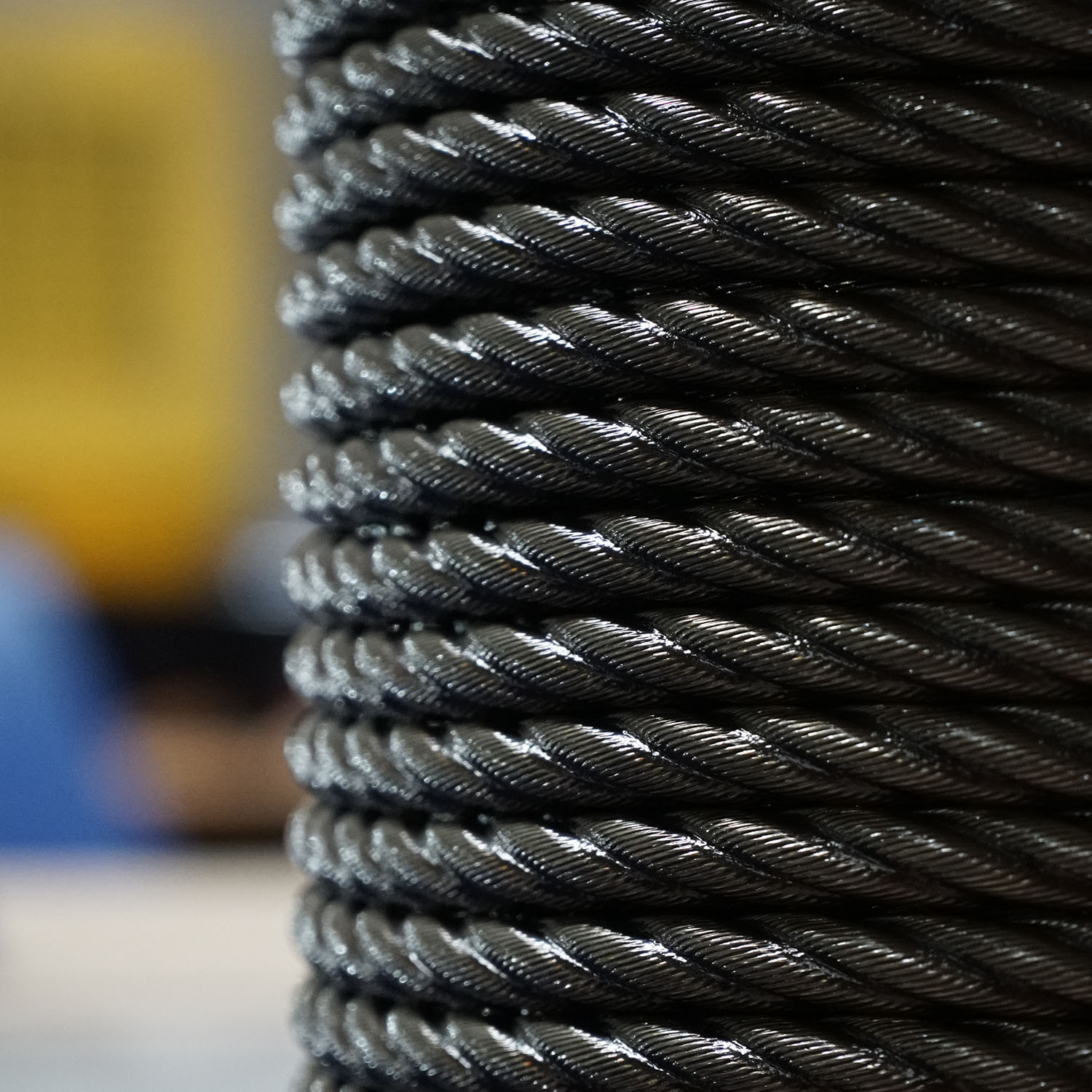

One important aspect of steel construction is the gauge of the steel wire used. The gauge of a steel wire refers to its diameter, with lower gauge numbers indicating thicker wire. In the case of the Twin Towers, the steel wire used was 9 gauge. This means that the diameter of the steel wire used in the construction of the Twin Towers was relatively thick, providing additional strength and support to the buildings.

Understanding the diameter of 9 gauge steel wire is important in the context of construction and structural engineering. Thicker steel wire, such as 9 gauge, is often used in applications where strength and durability are paramount. In the case of the Twin Towers, the use of 9 gauge steel wire helped to ensure the structural integrity of the buildings.

The diameter of 9 gauge steel wire is approximately 0.1144 inches, or 2.906 millimeters. This thickness is ideal for applications where high strength and durability are required, such as in the construction of tall buildings like the Twin Towers. The use of 9 gauge steel wire in the construction of the Twin Towers played a crucial role in their ability to withstand the forces placed upon them.

In addition to its strength and durability, 9 gauge steel wire is also relatively easy to work with. This makes it a popular choice for construction projects where precision and accuracy are important. The use of 9 gauge steel wire in the construction of the Twin Towers allowed for the creation of intricate and complex structural designs that helped to make the buildings stand out on the New York City skyline.

Overall, the steel used in the construction of the Twin Towers, including the 9 gauge steel wire, played a crucial role in the buildings’ structural integrity and overall design. The use of high-strength, low-alloy steel like ASTM A36, combined with the thickness of 9 gauge steel wire, helped to ensure that the Twin Towers were able to withstand the immense weight and stress placed upon them. The diameter of 9 gauge steel wire is just one example of the many factors that go into the construction of tall buildings and other structures.