Table of Contents

Differences between 304, 304L, 316, 316L, 347, 32750, 32760, and 904L Stainless Steel Pipes

Stainless steel is a popular material used in various industries due to its corrosion resistance, durability, and aesthetic appeal. When it comes to stainless Steel Pipes, there are several grades available, each with its own unique properties and applications. In this article, we will discuss the differences between some of the most commonly used stainless steel grades: 304, 304L, 316, 316L, 347, 32750, 32760, and 904L.

Let’s start with 304 stainless steel, which is one of the most widely used grades in the industry. It is known for its excellent corrosion resistance and is suitable for a wide range of applications, including food processing, chemical processing, and architectural applications. 304L is a low-carbon variant of 304, which offers improved weldability and formability. It is often used in applications where welding is required.

Moving on to 316 stainless steel, this grade is known for its superior corrosion resistance, especially in acidic environments. It is commonly used in marine applications, as well as in the pharmaceutical and medical industries. 316L is the low-carbon version of 316, which offers improved weldability and resistance to intergranular corrosion. It is often used in applications where high corrosion resistance is required.

347 stainless steel is a stabilized grade that contains niobium, which helps to prevent intergranular corrosion. It is commonly used in high-temperature applications, such as in the aerospace and power generation industries. 32750 and 32760 are super duplex stainless steels, which offer excellent corrosion resistance and high strength. They are commonly used in offshore and marine applications, as well as in the oil and gas industry.

Finally, 904L stainless steel is a high-alloy austenitic grade that offers excellent corrosion resistance in a wide range of environments, including sulfuric acid and chloride solutions. It is commonly used in chemical processing, pharmaceutical, and petrochemical industries.

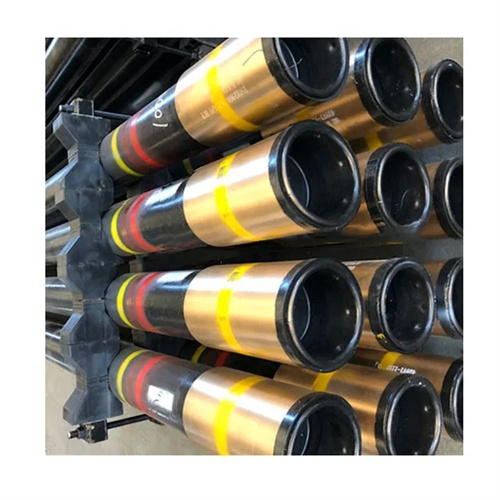

In terms of manufacturing processes, stainless steel pipes are available in two main types: welded and seamless. Welded pipes are made by welding a strip of stainless steel into a tube shape, while seamless pipes are made by extruding a solid billet of stainless steel through a die to form a tube. Both types of pipes have their own advantages and disadvantages.

Welded pipes are generally less expensive and are suitable for applications where high strength is not required. They are commonly used in structural applications, as well as in the automotive and construction industries. Seamless pipes, on the other hand, offer higher strength and are suitable for high-pressure and high-temperature applications. They are commonly used in the oil and gas industry, as well as in the chemical and petrochemical industries.

In conclusion, stainless steel pipes are available in a variety of grades and manufacturing processes, each with its own unique properties and applications. Understanding the differences between these grades can help you choose the right material for your specific needs. Whether you need a pipe for a high-temperature application or a corrosive Environment, there is a stainless steel grade that is suitable for your requirements.