Table of Contents

Benefits of Using API 5L Oil Casing and Tubing in Oil Well Operations

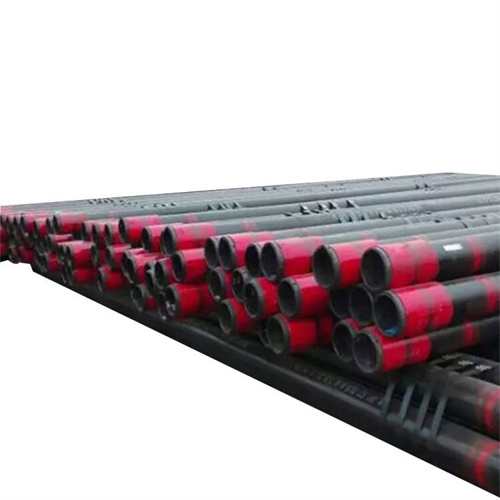

API 5L, API 5CT J55, K55, N80, L80, and P110 are all grades of oil casing and tubing that are commonly used in oil well operations. These materials are specifically designed to withstand the harsh conditions of oil drilling and extraction, providing a reliable and durable solution for protecting the wellbore and ensuring the efficient production of oil and gas.

One of the key benefits of using API 5L oil casing and tubing is their high strength and durability. These materials are manufactured to meet strict industry standards, ensuring that they can withstand the extreme pressures and temperatures that are often encountered in oil well operations. This means that they are less likely to fail or degrade over time, reducing the risk of costly downtime and repairs.

In addition to their strength, API 5L oil casing and tubing also offer excellent corrosion resistance. The materials used in their construction are specifically chosen for their ability to resist corrosion from the harsh Chemicals and fluids that are present in oil wells. This helps to prolong the life of the casing and tubing, ensuring that they can continue to protect the wellbore and maintain the integrity of the well for years to come.

Another benefit of using API 5L oil casing and tubing is their versatility. These materials are available in a range of grades and sizes, allowing them to be tailored to the specific requirements of each well. Whether drilling in shallow or deep wells, in onshore or offshore locations, there is an API 5L casing and tubing solution that can meet the needs of the operation.

Furthermore, API 5L oil casing and tubing are designed to be easy to install and maintain. Their standardized dimensions and connections make them simple to assemble and disassemble, reducing the time and labor required for installation and maintenance. This can help to streamline operations and minimize downtime, ultimately improving the efficiency and productivity of the well.

In addition to the benefits of using API 5L oil casing and tubing, it is also important to consider the environmental impact of these materials. By using high-quality, durable casing and tubing, operators can help to prevent leaks and spills that can harm the Environment and pose a risk to human health. This can help to ensure that oil well operations are conducted in a safe and responsible manner, protecting both the environment and the surrounding communities.

Overall, API 5L oil casing and tubing offer a range of benefits that make them an ideal choice for oil well operations. Their strength, durability, corrosion resistance, versatility, ease of installation, and environmental benefits all contribute to their value as a reliable and efficient solution for protecting the wellbore and ensuring the successful production of oil and gas. By choosing API 5L oil casing and tubing, operators can help to optimize their operations and minimize the risks associated with oil drilling and extraction.

Comparison of API 5CT Grades J55, K55, N80, L80, and P110 for Oil Casing and Tubing Applications

API 5CT is a standard specification for seamless casing and tubing used in the oil and gas industry. It sets out the technical requirements for the manufacture of these products, including chemical composition, mechanical properties, and testing procedures. Within the API 5CT standard, there are several grades of casing and tubing that are commonly used in oil well applications. These grades include J55, K55, N80, L80, and P110.

J55 is a commonly used grade of casing and tubing that has a minimum yield strength of 55,000 psi. It is typically used in shallow wells where the pressure is not as high. K55 is similar to J55 in terms of chemical composition and mechanical properties, but it has a higher minimum yield strength of 55,000 psi. This makes it suitable for deeper wells with higher pressure Levels.

N80 is a higher grade of casing and tubing with a minimum yield strength of 80,000 psi. It is commonly used in medium-depth wells where the pressure is moderate. N80 is known for its excellent resistance to corrosion and cracking, making it a popular choice for a wide range of oil well applications.

L80 is a higher grade of casing and tubing with a minimum yield strength of 80,000 psi. It is similar to N80 in terms of chemical composition and mechanical properties, but it has a higher resistance to corrosion and cracking. L80 is often used in wells with high pressure and high temperature conditions, where the casing and tubing are subjected to harsh environments.

P110 is the highest grade of casing and tubing with a minimum yield strength of 110,000 psi. It is designed for use in deep wells with high pressure and high temperature conditions. P110 has excellent mechanical properties and is known for its high resistance to corrosion and cracking. It is often used in challenging oil well applications where other grades of casing and tubing may not be suitable.

When comparing the different grades of API 5CT casing and tubing, it is important to consider the specific requirements of the well and the operating conditions. J55 and K55 are suitable for shallow wells with lower pressure levels, while N80 and L80 are better suited for medium-depth wells with moderate pressure. P110 is the best choice for deep wells with high pressure and high temperature conditions.

In conclusion, API 5CT grades J55, K55, N80, L80, and P110 offer a range of options for oil casing and tubing applications. Each grade has its own unique properties and strengths, making it important to carefully consider the specific requirements of the well before selecting the appropriate grade. By understanding the differences between these grades, oil and gas companies can make informed decisions when choosing casing and tubing for their wells.