Table of Contents

Benefits of Using Asphalt Warm Mix Additive

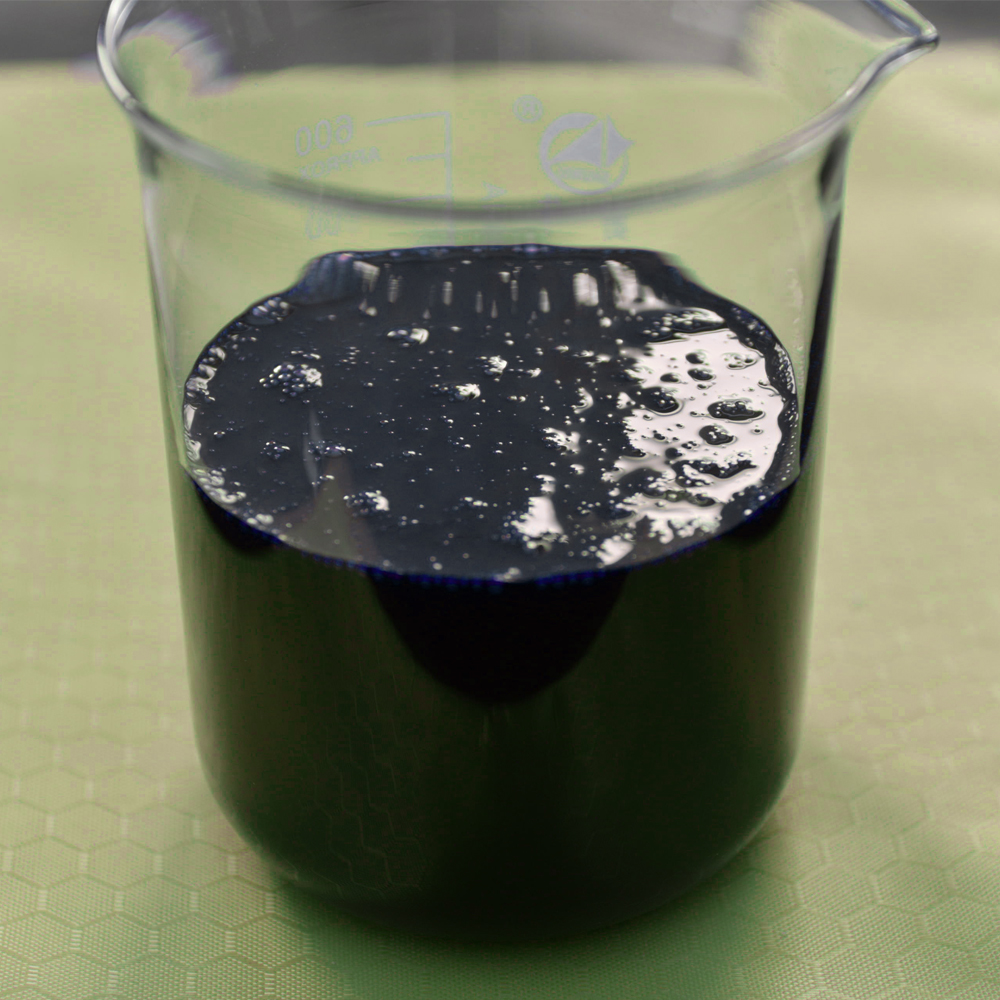

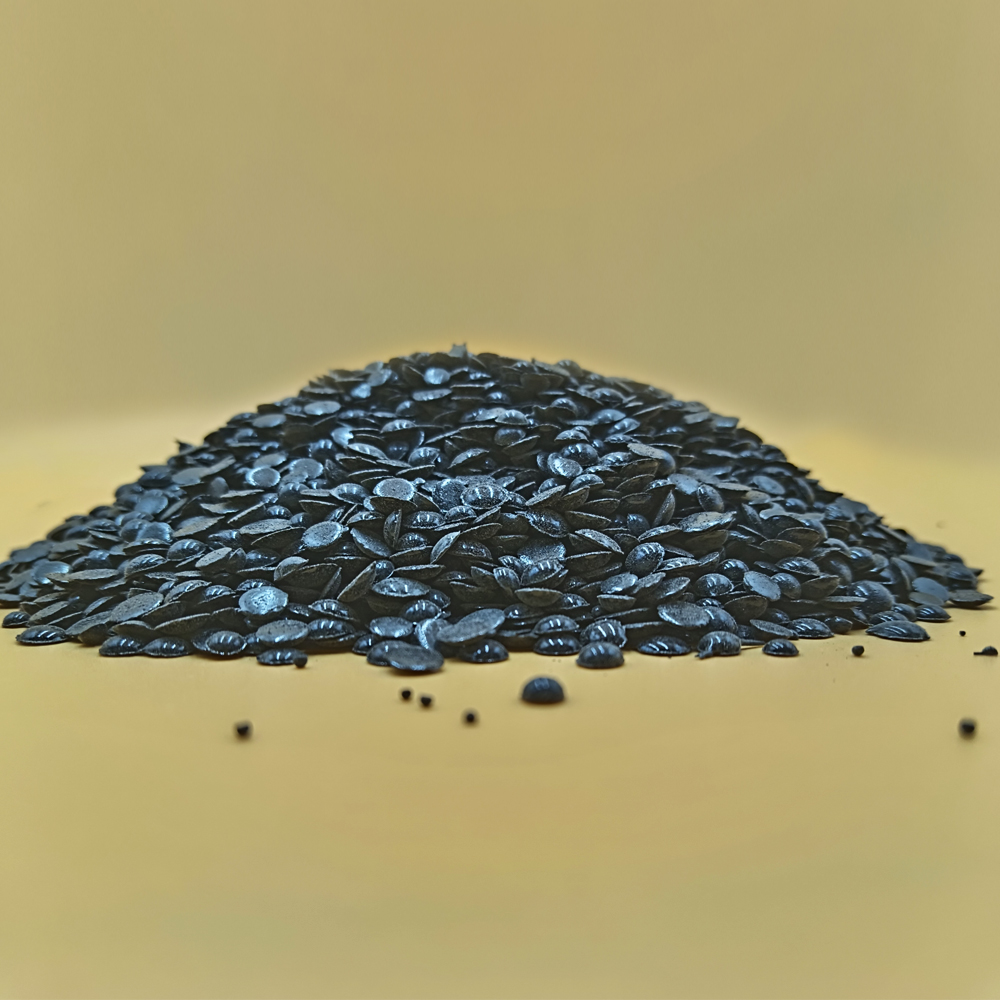

Asphalt warm mix additives have become increasingly popular in the construction industry due to their numerous benefits. These additives are designed to lower the production and placement temperatures of asphalt mixtures, resulting in reduced energy consumption, lower emissions, and improved workability. One such additive that has gained recognition for its effectiveness is the Asphalt Warm Mixing Enhancer.

| Serial Number | Article Name |

| 1 | Rut Resistance modifier for Asphalt |

| No. | Commodity Name |

| 1 | Liquid Anti-strip agent |

The Asphalt Warm Mixing Enhancer is a specially formulated additive that is added to asphalt mixtures to improve their workability and performance at lower temperatures. By reducing the viscosity of the asphalt binder, this additive allows for easier mixing and compaction, resulting in a more uniform and durable pavement. In addition, the use of warm mix additives like the Asphalt Warm Mixing Enhancer can help reduce the amount of energy required to produce and place asphalt mixtures, leading to cost savings and environmental benefits.

| Number | Item |

| 1 | natural cellulosic fibers |

| Serial Number | Product |

| 1 | Asphalt paving modifiers |

One of the key benefits of using the Asphalt Warm Mixing Enhancer is its ability to lower the production and placement temperatures of asphalt mixtures. By reducing the temperature at which the asphalt binder becomes workable, this additive can help contractors extend the paving season and work more efficiently in colder weather conditions. This can be particularly beneficial in regions with shorter construction seasons or where traditional hot mix asphalt may be difficult to produce and place.

| No. | Product |

| 1 | High viscosity asphalt agent |

In addition to improving workability and extending the paving season, the Asphalt Warm Mixing Enhancer can also help reduce emissions and improve air quality. By lowering the production temperatures of asphalt mixtures, this additive can reduce the amount of energy required to heat the asphalt binder, resulting in lower greenhouse gas emissions and other pollutants. This can help contractors meet environmental regulations and sustainability goals while still achieving high-quality pavement performance.

Furthermore, the use of warm mix additives like the Asphalt Warm Mixing Enhancer can Lead to cost savings for contractors and project owners. By reducing the amount of energy needed to produce and place asphalt mixtures, this additive can help lower production costs and improve overall project economics. In addition, the improved workability and compaction of warm mix asphalt can result in a more durable pavement that requires less maintenance over time, further reducing long-term costs for project owners.

Overall, the benefits of using the Asphalt Warm Mixing Enhancer are clear. From improved workability and extended paving seasons to reduced emissions and cost savings, this additive offers a range of advantages for contractors and project owners alike. By incorporating warm mix additives into their asphalt mixtures, construction professionals can achieve high-quality pavement performance while also meeting environmental and economic goals. As the construction industry continues to prioritize sustainability and efficiency, the Asphalt Warm Mixing Enhancer is sure to play a key role in shaping the future of asphalt pavement technology.

How Asphalt Warm Mixing Enhancer Improves Road Construction

Asphalt warm mixing enhancer is a crucial component in improving road construction processes. This additive is designed to lower the production temperature of asphalt mixtures, making them easier to work with and more environmentally friendly. By using warm mix technology, construction crews can reduce energy consumption, emissions, and overall costs while still achieving high-quality results.

One of the key benefits of using an asphalt warm mixing enhancer is the ability to lower the production temperature of asphalt mixtures. Traditional hot mix asphalt requires high temperatures to be produced, which can be both costly and energy-intensive. By incorporating warm mix technology into the production process, construction crews can reduce the temperature at which the asphalt is mixed and laid, resulting in significant energy savings.

In addition to reducing energy consumption, warm mix technology also helps to lower emissions during the production process. The lower temperatures required for warm mix asphalt production result in reduced emissions of greenhouse gases and other pollutants. This is not only beneficial for the Environment but also for the health and Safety of construction workers and nearby residents.

Furthermore, using an asphalt warm mixing enhancer can lead to cost savings for construction companies. By lowering the production temperature of asphalt mixtures, crews can reduce the amount of fuel needed to heat the materials, resulting in lower operating costs. Additionally, the use of warm mix technology can extend the paving season, allowing construction crews to work in colder temperatures and in regions where traditional hot mix asphalt may not be feasible.

| Nr. | Name |

| 1 | for Streets anti Crack Fiber |

| Number | Commodity Name |

| 1 | Warm asphalt mixture constituents |

Another advantage of using an asphalt warm mixing enhancer is the improved workability of the asphalt mixtures. Warm mix technology allows for better coating and adhesion of the asphalt binder to the aggregate particles, resulting in a more durable and long-lasting pavement. This can help to reduce maintenance costs and extend the lifespan of the road, ultimately saving money for both construction companies and taxpayers.

| Nr. | Products |

| 1 | Basalt fiber structural reinforcement |

Overall, asphalt warm mixing enhancer plays a crucial role in improving road construction processes. By lowering production temperatures, reducing emissions, and improving workability, this additive offers a wide range of benefits for construction companies, the environment, and the community. As the demand for sustainable and cost-effective construction practices continues to grow, warm mix technology is becoming an increasingly popular choice for road projects around the world. By incorporating an asphalt warm mixing enhancer into their production processes, construction companies can achieve high-quality results while also reducing their environmental impact and operating costs.