Table of Contents

Benefits of Using Asphalt Pavement Cold-Resistant Additives

Asphalt pavement is a popular choice for road construction due to its durability and cost-effectiveness. However, one of the challenges faced by asphalt pavement is its susceptibility to cold temperatures, which can cause cracking and deterioration. To address this issue, liquid anti-aging asphalt additives have been developed to improve the cold resistance of asphalt pavement.

These additives are designed to enhance the performance of asphalt pavement in cold weather conditions by increasing its flexibility and resistance to cracking. By incorporating these additives into the asphalt mix, road builders can create a more durable and long-lasting pavement that can withstand the rigors of winter weather.

One of the key benefits of using asphalt pavement cold-resistant additives is the extended lifespan of the pavement. Cold temperatures can cause asphalt pavement to become brittle and prone to cracking, leading to costly repairs and maintenance. By using anti-aging additives, road builders can significantly increase the lifespan of the pavement, reducing the need for frequent repairs and saving money in the long run.

In addition to improving the durability of asphalt pavement, cold-resistant additives can also enhance the Safety of the road. Cracks and potholes in the pavement can pose a hazard to drivers, especially in icy or snowy conditions. By using anti-aging additives to prevent cracking and deterioration, road builders can create a smoother and safer driving surface for motorists.

Furthermore, asphalt pavement cold-resistant additives can also help reduce the environmental impact of road construction. By extending the lifespan of the pavement, fewer materials are needed for repairs and maintenance, reducing the amount of waste generated from road construction projects. Additionally, the improved durability of the pavement means fewer disruptions to traffic flow due to road closures for repairs, resulting in reduced emissions from idling vehicles.

Overall, the use of liquid anti-aging asphalt additives offers a wide range of benefits for road builders and motorists alike. By improving the cold resistance of asphalt pavement, these additives can extend the lifespan of the pavement, enhance safety, and reduce the environmental impact of road construction. With the increasing demand for durable and sustainable infrastructure, asphalt pavement cold-resistant additives are becoming an essential tool for road builders looking to create long-lasting and resilient roads.

In conclusion, the benefits of using asphalt pavement cold-resistant additives are clear. By incorporating these additives into the asphalt mix, road builders can create a more durable, safe, and environmentally friendly pavement that can withstand the challenges of cold weather. As the demand for sustainable infrastructure continues to grow, the use of liquid anti-aging asphalt additives will play an increasingly important role in the construction of resilient and long-lasting roads.

How Liquid Anti-Aging Asphalt Additives Improve Pavement Durability

Asphalt pavement is a crucial component of our transportation infrastructure, providing a smooth and durable surface for vehicles to travel on. However, over time, asphalt pavement can deteriorate due to a variety of factors, including weather conditions, traffic loads, and aging. One of the most common issues that asphalt pavement faces is aging, which can Lead to cracking, rutting, and other forms of deterioration. To combat this problem, liquid anti-aging asphalt additives have been developed to improve the durability and longevity of asphalt pavement.

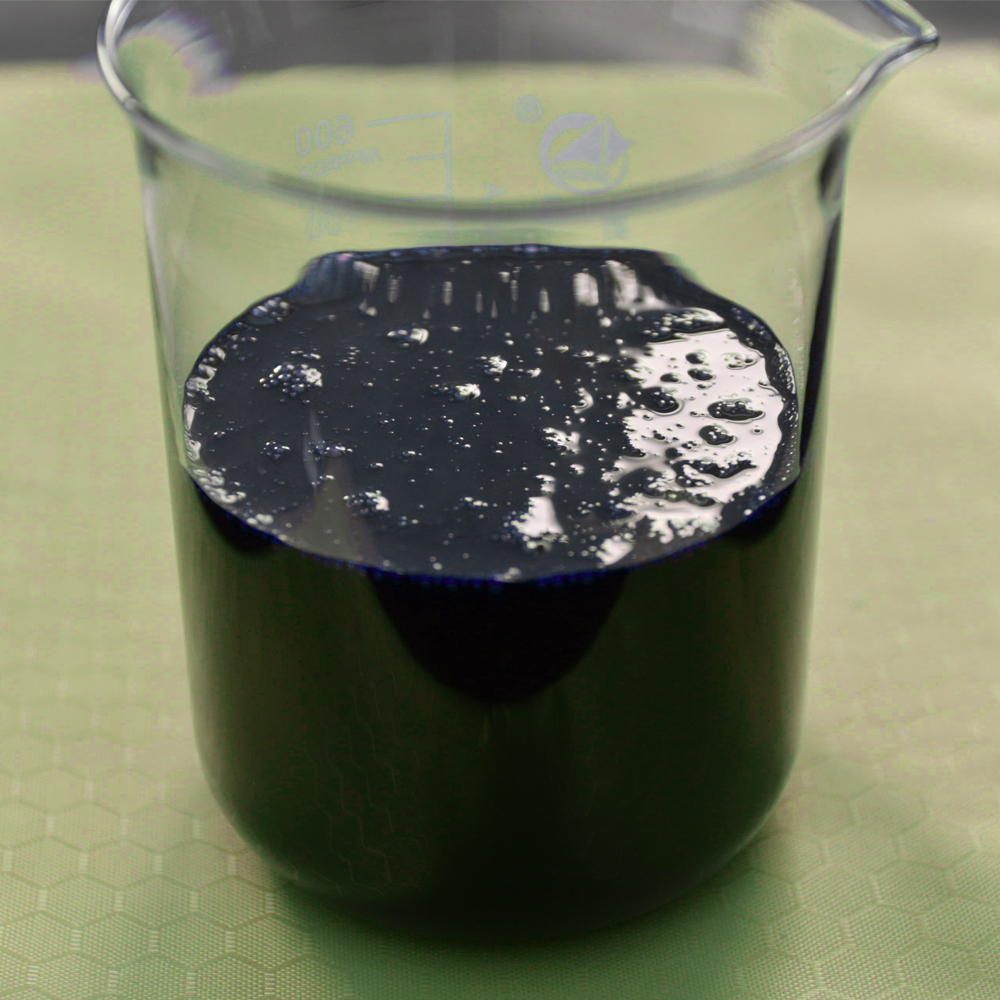

Liquid anti-aging asphalt additives are specially formulated Chemicals that are mixed with asphalt during the production process. These additives work by enhancing the properties of the asphalt binder, making it more resistant to the effects of aging. One of the key benefits of using liquid anti-aging asphalt additives is that they help to prevent the oxidation of the asphalt binder, which is a common cause of aging in asphalt pavement. By reducing oxidation, these additives can help to maintain the flexibility and elasticity of the asphalt binder, preventing it from becoming brittle and prone to cracking.

| Part | Name |

| 1 | Road construction mixtures |

In addition to preventing oxidation, liquid anti-aging asphalt additives also help to improve the overall durability of the asphalt pavement. These additives can enhance the adhesion between the asphalt binder and the aggregate, creating a stronger and more cohesive pavement structure. This improved adhesion helps to reduce the risk of rutting and other forms of deformation, ensuring that the pavement remains smooth and stable under heavy traffic loads.

Another important benefit of using liquid anti-aging asphalt additives is that they can help to improve the cold-resistance of the pavement. Cold temperatures can cause asphalt pavement to become stiff and brittle, increasing the risk of cracking and other forms of damage. By enhancing the flexibility and elasticity of the asphalt binder, these additives can help to maintain the integrity of the pavement even in cold weather conditions. This can help to extend the lifespan of the pavement and reduce the need for costly repairs and maintenance.

Overall, liquid anti-aging asphalt additives play a crucial role in improving the durability and longevity of asphalt pavement. By preventing oxidation, enhancing adhesion, and improving cold-resistance, these additives can help to ensure that the pavement remains in good condition for many years to come. As our transportation infrastructure continues to face increasing demands, the use of liquid anti-aging asphalt additives will become increasingly important in maintaining the safety and efficiency of our roadways. By investing in these additives, we can help to protect our infrastructure and ensure that our roads remain smooth and reliable for all users.