Table of Contents

Noise Reduction Techniques for CNC Equipment

Noise Reduction Techniques for CNC Equipment

In the world of manufacturing, CNC equipment plays a crucial role in producing high-quality products efficiently. However, one common issue that many manufacturers face is the noise generated by CNC equipment during operation. This noise can be not only disruptive to workers but also a sign of potential problems within the equipment itself. In order to address this issue, it is important to implement noise reduction techniques that can help minimize the noise Levels produced by CNC equipment.

One effective way to reduce noise in CNC equipment is by ensuring that the motor and reducer are properly matched. When the motor and reducer are not properly matched, it can Lead to increased noise levels as the equipment struggles to operate efficiently. By ensuring that the motor and reducer are compatible and properly matched, manufacturers can help reduce the overall noise levels produced by the CNC equipment.

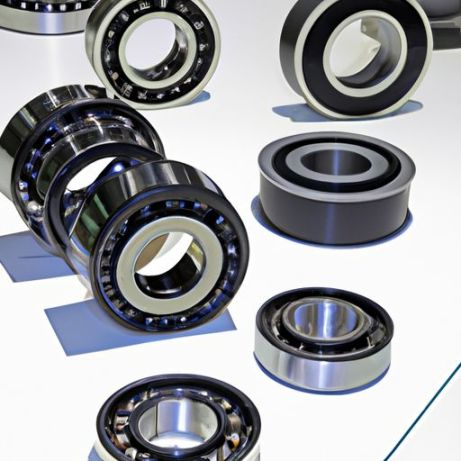

Another important factor to consider when trying to reduce noise in CNC equipment is the use of Special Bearings. Special bearings, such as the 6305-2RZ bearing, are designed to help reduce noise levels and improve the overall performance of the equipment. These bearings are specifically engineered to withstand high speeds and low temperatures, making them ideal for use in CNC equipment where noise reduction is a priority.

In addition to using special bearings, manufacturers can also implement other noise reduction techniques such as proper lubrication and maintenance of the equipment. By ensuring that the equipment is properly lubricated and maintained, manufacturers can help reduce the friction and wear that can lead to increased noise levels. Regular maintenance checks can also help identify any potential issues before they escalate into larger problems that can result in increased noise levels.

Furthermore, manufacturers can also consider implementing soundproofing measures in the manufacturing facility to help reduce the overall noise levels produced by CNC equipment. Soundproofing Materials such as Acoustic Panels and sound-absorbing foam can help absorb and reduce the noise generated by the equipment, creating a quieter and more comfortable work Environment for employees.

In conclusion, noise reduction techniques are essential for minimizing the noise levels produced by CNC equipment. By ensuring that the motor and reducer are properly matched, using special bearings designed for high-speed and low-temperature applications, and implementing proper lubrication and maintenance practices, manufacturers can help reduce the overall noise levels produced by CNC equipment. Additionally, soundproofing measures can also be implemented to further reduce noise levels in the manufacturing facility. By taking these steps, manufacturers can create a quieter and more efficient work environment for employees while also prolonging the life of their CNC equipment.

Matching Bearings for Special CNC Equipment: 6305-2RZ High Speed Low Friction Bearings

In the world of CNC equipment, precision and efficiency are key factors in ensuring optimal performance. One crucial component that plays a significant role in the overall functionality of CNC machines is the bearing. Bearings are essential in reducing friction and ensuring smooth operation of rotating parts in CNC equipment. When it comes to matching bearings for special CNC equipment, the 6305-2RZ high-speed low-friction bearing stands out as a top choice for many manufacturers and operators.

The 6305-2RZ bearing is specially designed to meet the demands of high-speed CNC equipment while maintaining low friction levels. This makes it an ideal choice for applications where noise reduction and energy efficiency are crucial. The 6305-2RZ bearing is known for its ability to operate at high speeds without compromising on performance, making it a popular choice for CNC machines that require precision and reliability.

One of the key features of the 6305-2RZ bearing is its reduced noise levels. In CNC equipment, noise can be a significant issue, affecting both the performance of the machine and the working environment. The 6305-2RZ bearing is designed to minimize noise levels, ensuring a quieter operation that is more conducive to a productive work environment. This makes it an excellent choice for CNC machines that are used in noise-sensitive environments or require precision Machining.

Another important factor to consider when choosing bearings for CNC equipment is friction. Friction can have a significant impact on the performance and efficiency of CNC machines, affecting both the speed and accuracy of the machining process. The 6305-2RZ bearing is specifically designed to reduce friction levels, ensuring smooth operation and optimal performance. This makes it an ideal choice for CNC machines that require high-speed operation and precision machining.

The 6305-2RZ bearing is also known for its high-speed capabilities. In CNC equipment, speed is a critical factor in determining the efficiency and productivity of the machine. The 6305-2RZ bearing is designed to operate at high speeds, making it an excellent choice for CNC machines that require fast and accurate machining. This high-speed capability ensures that the machine can handle demanding machining tasks with ease, resulting in improved productivity and performance.

Overall, the 6305-2RZ high-speed low-friction bearing is a top choice for matching bearings for special CNC equipment. Its ability to reduce noise levels, minimize friction, and operate at high speeds makes it an ideal choice for CNC machines that require precision, efficiency, and reliability. By choosing the 6305-2RZ bearing for your CNC equipment, you can ensure optimal performance and longevity, ultimately leading to improved productivity and profitability.