Table of Contents

Benefits of Using API5CT J55, N80, L80, N80q, P110 Casing Seamless Pipe in Oil and Gas Industry

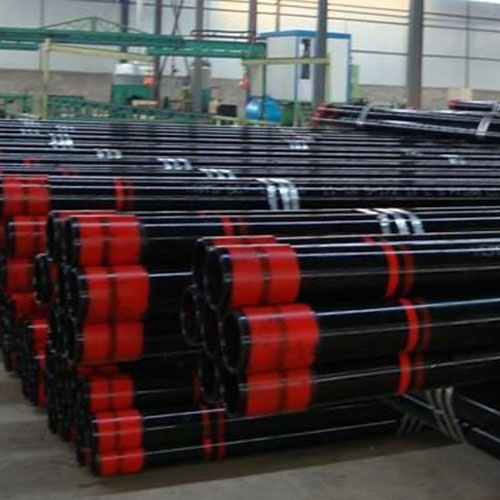

The oil and gas industry relies heavily on the use of high-quality casing seamless pipes to ensure the efficient and safe extraction of oil and gas from the ground. API5CT J55, N80, L80, N80q, and P110 are some of the most commonly used grades of casing seamless pipes in the industry. These pipes are designed to withstand high pressure, corrosive environments, and extreme temperatures, making them ideal for use in oil and gas wells.

One of the key benefits of using API5CT J55, N80, L80, N80q, and P110 casing seamless pipes is their high strength and durability. These pipes are made from high-quality steel that has been carefully engineered to meet the rigorous demands of the oil and gas industry. This means that they can withstand the high pressures and temperatures that are often encountered in oil and gas wells, ensuring that they provide reliable performance over the long term.

In addition to their strength and durability, API5CT J55, N80, L80, N80q, and P110 casing seamless pipes also offer excellent corrosion resistance. This is crucial in the oil and gas industry, where pipes are constantly exposed to corrosive substances such as saltwater, hydrogen sulfide, and Other Chemicals. By using corrosion-resistant casing seamless pipes, companies can minimize the risk of pipe failure and ensure the Safety and integrity of their operations.

Another benefit of using API5CT J55, N80, L80, N80q, and P110 casing seamless pipes is their versatility. These pipes are available in a wide range of sizes and specifications, making them suitable for a variety of applications in the oil and gas industry. Whether companies are drilling in shallow or deep wells, onshore or offshore, or in conventional or unconventional reservoirs, there is a casing seamless pipe that can meet their specific needs.

Furthermore, API5CT J55, N80, L80, N80q, and P110 casing seamless pipes are easy to install and maintain, reducing downtime and increasing operational efficiency. Their seamless design eliminates the need for welding, which can weaken the pipe and increase the risk of failure. Additionally, these pipes are designed to be easily connected and disconnected, allowing for quick and efficient installation and removal as needed.

https://www.youtube.com/watch?v=z-oXqbR-OFYOverall, the use of API5CT J55, N80, L80, N80q, and P110 casing seamless pipes offers numerous benefits to companies in the oil and gas industry. From their high strength and durability to their corrosion resistance, versatility, and ease of installation, these pipes are an essential component of any successful oil and gas operation. By choosing the right grade of casing seamless pipe for their specific needs, companies can ensure the safety, efficiency, and reliability of their operations for years to come.

Comparison of API5CT J55, N80, L80, N80q, P110 Casing Seamless Pipe Grades

API5CT J55, N80, L80, N80q, and P110 are all grades of casing seamless pipes that are commonly used in the oil and gas industry. Each grade has its own unique properties and characteristics that make it suitable for different applications. In this article, we will compare these grades to help you understand their differences and choose the right one for your specific needs.

Let’s start with API5CT J55. This grade is the lowest strength casing pipe in the API5CT specification. It has a minimum yield strength of 55,000 psi and a minimum tensile strength of 75,000 psi. J55 is commonly used in shallow wells where the pressure is not too high. It is also suitable for wells with mild sour conditions. However, J55 is not recommended for wells with high pressure or high sour conditions due to its lower strength.

Next, we have N80. N80 is a medium-strength casing pipe with a minimum yield strength of 80,000 psi and a minimum tensile strength of 100,000 psi. N80 is a popular choice for wells with moderate to high pressure and sour conditions. It is also commonly used in deep wells where the pressure is high. N80 is known for its good mechanical properties and resistance to corrosion. It is a versatile grade that can be used in a wide range of applications.

Moving on to L80. L80 is a higher-strength casing pipe with a minimum yield strength of 80,000 psi and a minimum tensile strength of 95,000 psi. L80 is often used in wells with high pressure and high temperature conditions. It is also suitable for wells with moderate sour conditions. L80 is known for its excellent mechanical properties and resistance to corrosion. It is a reliable grade that can withstand harsh operating conditions.

N80q is a modified version of N80 with higher mechanical properties. It has a minimum yield strength of 80,000 psi and a minimum tensile strength of 110,000 psi. N80q is designed for wells with high pressure and high temperature conditions. It is also suitable for wells with severe sour conditions. N80q is known for its superior mechanical properties and resistance to corrosion. It is a premium grade that is used in demanding applications.

Lastly, we have P110. P110 is the highest-strength casing pipe in the API5CT specification. It has a minimum yield strength of 110,000 psi and a minimum tensile strength of 140,000 psi. P110 is commonly used in wells with very high pressure and high temperature conditions. It is also suitable for wells with severe sour conditions. P110 is known for its exceptional mechanical properties and resistance to corrosion. It is a premium grade that is used in the most demanding applications.

In conclusion, API5CT J55, N80, L80, N80q, and P110 are all grades of casing seamless pipes that are used in the oil and gas industry. Each grade has its own unique properties and characteristics that make it suitable for different applications. When choosing a grade, it is important to consider the specific requirements of your well, such as pressure, temperature, and sour conditions. By understanding the differences between these grades, you can select the right one for your specific needs.