Table of Contents

Benefits of Using 8 Head Automatic Pick Nozzle in Electronics Production Machinery

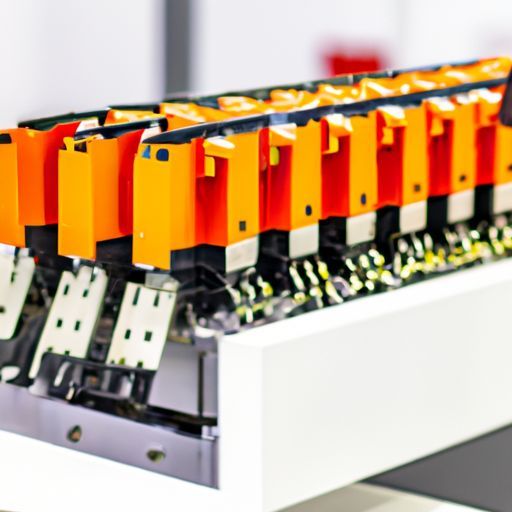

In the fast-paced world of electronics production, efficiency and precision are key factors in ensuring high-quality products are manufactured in a timely manner. One crucial component in this process is the pick and place machine, which is responsible for accurately placing electronic components onto printed circuit Boards (PCBs). To enhance the performance of these machines, many manufacturers are turning to the use of 8 head automatic pick nozzles.

These advanced pick nozzles offer a number of benefits that can significantly improve the efficiency and accuracy of electronics production machinery. One of the key advantages of using an 8 head automatic pick nozzle is the ability to pick up multiple components simultaneously. This feature allows for faster placement of components onto the PCB, reducing production time and increasing overall output.

In addition to speed, the precision of the 8 head automatic pick nozzle is unmatched. The advanced technology used in these nozzles ensures that components are placed with the utmost accuracy, minimizing the risk of errors and defects in the final product. This level of precision is essential in the production of high-quality electronic products, where even the smallest deviation can result in a malfunctioning device.

Another benefit of using an 8 head automatic pick nozzle is the versatility it offers in terms of component size and shape. These nozzles are designed to accommodate a wide range of component sizes, from tiny Resistors and Capacitors to larger ICs and Connectors. This flexibility allows manufacturers to produce a variety of electronic products without the need for multiple pick and place machines, saving both time and money.

Furthermore, the high speed of the 8 head automatic pick nozzle can greatly increase the overall productivity of electronics production machinery. By reducing the time it takes to place components onto the PCB, manufacturers can produce more products in a shorter amount of time, ultimately leading to higher profits and a competitive edge in the market.

In addition to speed and precision, the 8 head automatic pick nozzle also offers ease of use and maintenance. These nozzles are designed to be user-friendly, with intuitive controls and minimal setup required. This allows operators to quickly learn how to use the machine and make adjustments as needed, reducing downtime and increasing overall efficiency.

Furthermore, the advanced technology used in 8 head automatic pick nozzles ensures that they require minimal maintenance and upkeep. This means that manufacturers can focus on production without having to worry about constant repairs or replacements, saving both time and money in the long run.

Overall, the benefits of using an 8 head automatic pick nozzle in electronics production machinery are clear. From increased speed and precision to versatility and ease of use, these advanced pick nozzles offer a number of advantages that can greatly improve the efficiency and productivity of electronics manufacturing. By investing in this technology, manufacturers can stay ahead of the competition and produce high-quality electronic products that meet the demands of today’s market.

Step-by-Step Guide on Using Place Machine LED Making Machine for PCB Production in Electronic Products Machinery High Speed

In the world of electronics production, efficiency and precision are key factors in ensuring high-quality products. One essential piece of equipment that plays a crucial role in the production process is the pick and place machine. This machine is responsible for accurately placing electronic components onto printed circuit boards (PCBs) with speed and accuracy. One popular type of pick and place machine is the 8 head automatic pick nozzle machine, which is designed to handle a wide range of components and speeds up the production process significantly.

When it comes to PCB production, the pick and place machine is a vital component in the Assembly Line. This machine is responsible for picking up electronic components from reels or trays and placing them onto the PCB with precision. The 8 head automatic pick nozzle machine is equipped with eight individual nozzles, allowing it to pick up multiple components simultaneously and place them onto the PCB in a single pass. This not only speeds up the production process but also ensures that components are placed accurately and securely.

Using a pick and place machine like the 8 head automatic pick nozzle machine requires careful calibration and setup to ensure optimal performance. The first step in using this machine is to load the components onto the reels or trays and input the placement data into the machine’s Software. This data includes the coordinates for each component on the PCB, as well as information on the component size and orientation.

Once the machine is loaded with the necessary components and the placement data is inputted, the next step is to calibrate the machine. This involves adjusting the placement heads and nozzles to ensure that they are aligned correctly and can pick up and place components accurately. Calibration is a crucial step in the setup process, as it ensures that the machine will operate smoothly and efficiently during production.

After the machine is calibrated, it is ready to start the production process. The machine will automatically pick up components from the reels or trays and place them onto the PCB according to the placement data inputted into the software. The 8 head automatic pick nozzle machine is capable of placing components at high speeds, making it ideal for high-volume production runs.

One of the key advantages of using a pick and place machine like the 8 head automatic pick nozzle machine is its ability to handle a wide range of components. This machine is equipped with multiple nozzles of varying sizes, allowing it to pick up components of different shapes and sizes with ease. This versatility makes the machine suitable for a variety of electronic products, from small Consumer Electronics to larger industrial equipment.

In conclusion, the 8 head automatic pick nozzle machine is a valuable tool in the electronics production process. Its ability to handle multiple components simultaneously and place them onto PCBs with speed and accuracy makes it an essential piece of equipment for high-speed production lines. By following the steps outlined in this guide, users can effectively utilize this machine to streamline their PCB production process and produce high-quality electronic products efficiently.